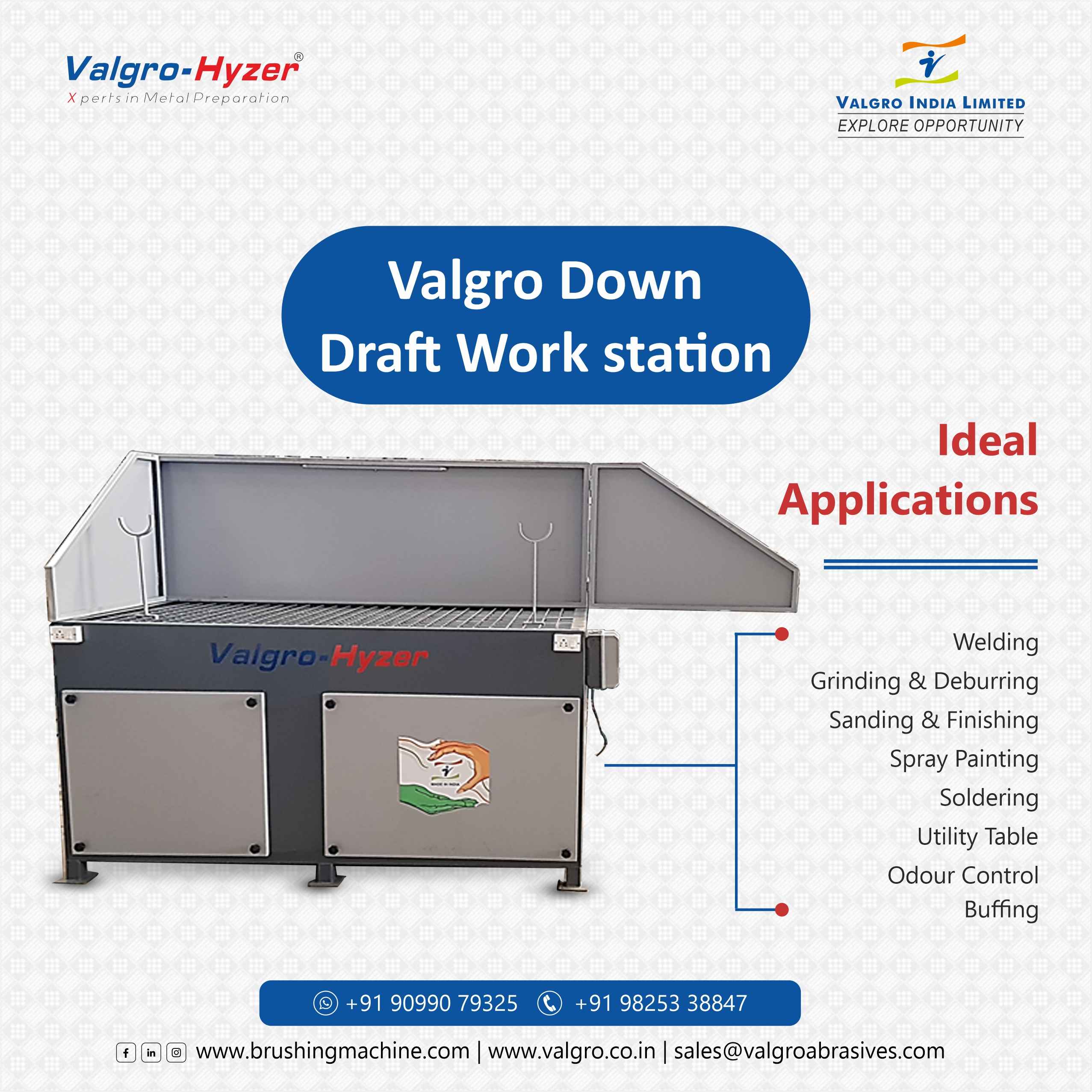

Installing high-quality downdraft tables as part of your production process will provide workers with a safe environment to accomplish their work while ensuring a high level of quality and performance to which you’ve grown accustomed. Downdraft tables have the ability to capture fine dust particles, smoke and fumes at the source, so you don’t have to be concerned about workplace contamination or health conditions affecting your employees.

Features:

- Highly efficient collection either via back and side walls or centrally underneath the work surface

- Height-adjustable and ergonomically designed workplace system

- Modular design and different sizes depending on the application

- Flexible or rigid side walls

- Various work supports

- Simple disposal of discharged material

- Great freedom of movement and legroom

One of the most significant benefits of a downdraft table is that it minimises employees’ exposure to contaminated air. When employees are working, many contaminants are produced, such as fine particles, dust, smoke, and other harmful pollutants, which can end up in the workers’ eyes, nose, and lungs.

Save lifeFine dust can settle in lung tissue and cause scarring and inflammation, impairing normal lung function. Some types of fine dust can travel to the bloodstream, where they can affect the kidneys, liver or brain. Inhaling workplace fumes is no better, and often produces acute effects that require immediate medical intervention.

Technical Specification

- Welding – Ideal capture-at-source equipment for heavy-duty welding applications like stick welding, MIG and TIG welding.

- Deburring – Using quality capture-at-source equipment is the only effective way to eliminate fine dust from the environment when abrasives are used to deburr, polish or finish fabricated materials.

- Grinding – When grinding metals or plastics, a well-ventilated downdraft table will remove dust particles at the source and greatly improve air quality.

- Sanding – Sanding applications are common with wood, metal or plastic, and containing the dust that’s produced is crucial to a safe workplace.

- Cutting – Plasma cutting applications can produce toxic fumes, gasses and particles, but a high-quality downdraft table provides a safe and efficient solution.

- Mixing – When combining granules or powders in an industrial workspace, maintaining air quality is challenging, but a well-placed downdraft table makes all the difference.