Knowledge of daily maintenance of polishing machine

All equipment’s needs Maintenance. Depending upon the work conditions the Maintenance varies proportionately.

We often hear of certain Machinery being “Not Good or Bad”.

The fact of matter is machinery needs periodic maintenance. When not done over a long time, no matter how good the machinery be, there will be problems.

Hence, maintenance is particularly important.

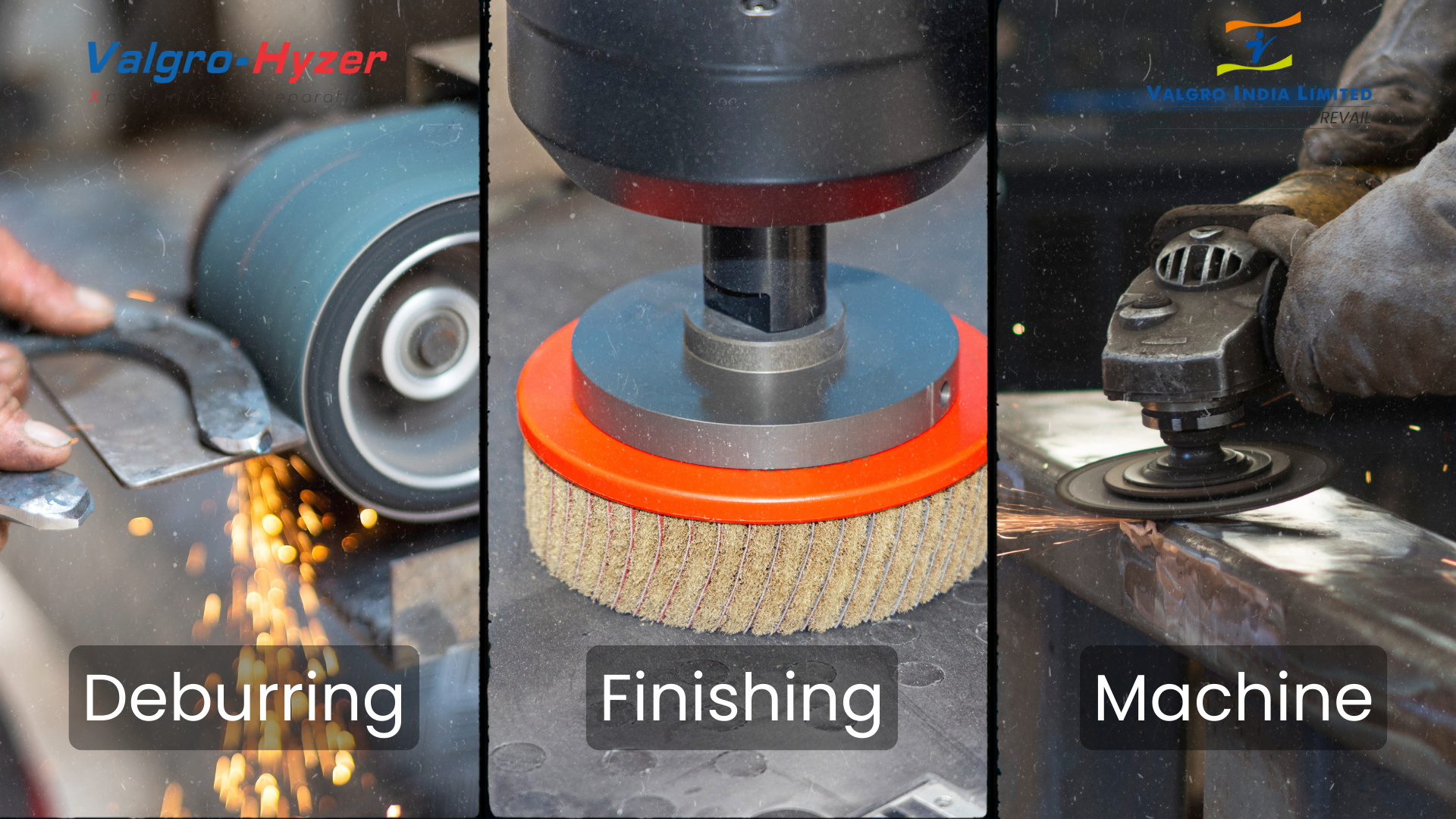

Now, let us introduce the daily maintenance of the polishing machine and wire drawing machine.

1. If there is a lot of dust accumulation, you must remove the motor casing and use a vacuum cleaner to remove the dust

2. After each use, clean the surface of the machine with a clean cloth. Disconnect the power supply.

3. After each use, the body should be wiped clean.

4. Lubricate the wheels and other moving parts every half a month.

5. Check whether the power cord is damaged before operation.

for more detail please mail us sales@valgroabrasives.com