Valgro Heavy Duty Grinding Machines need coolant to cool and lubricate the grinding process and to remove the sludge from the grinding cabin. Emulsion or Grinding Oil has been developed specially for this process and they are well proved to enhance the lifetime of the grinding belts. VALGRO INDIA has designed and continuously developed wet type belt grinding machines, which work reliable in the rough environment. Wet grinding available with coolant circulation system & filtration unit, Mist exhaust system with proven technology, and process automation.

Feature :

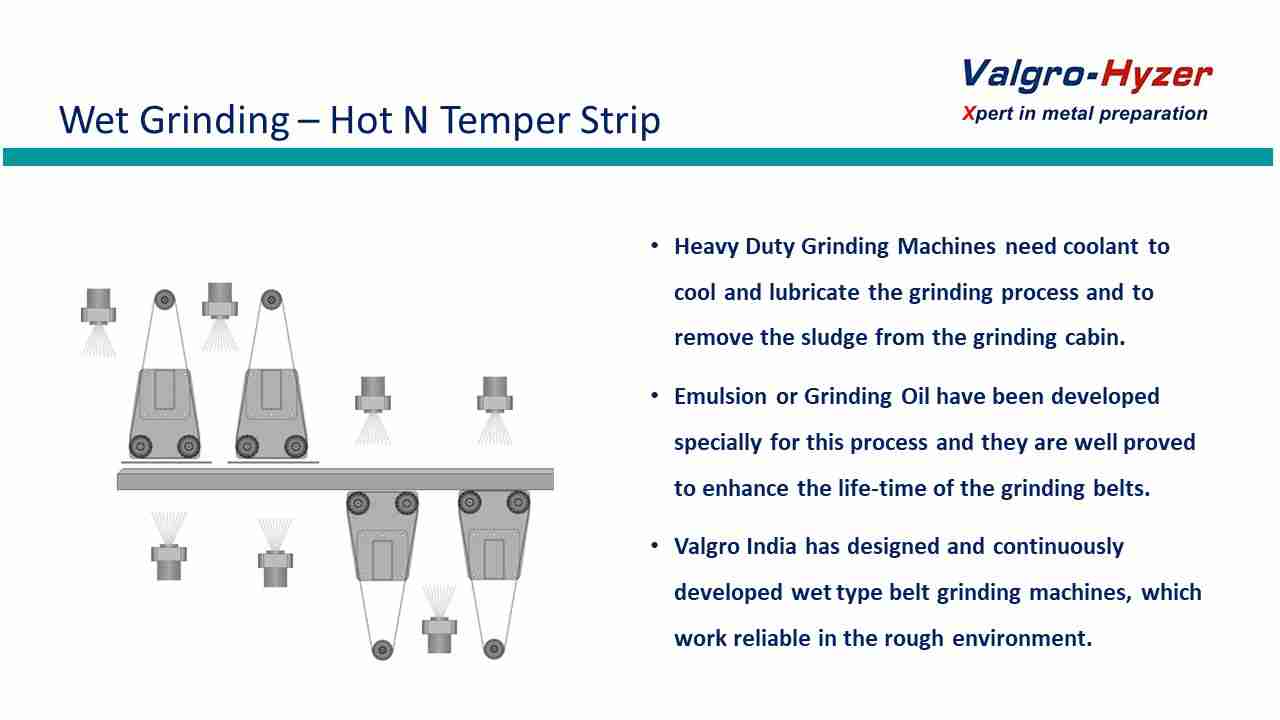

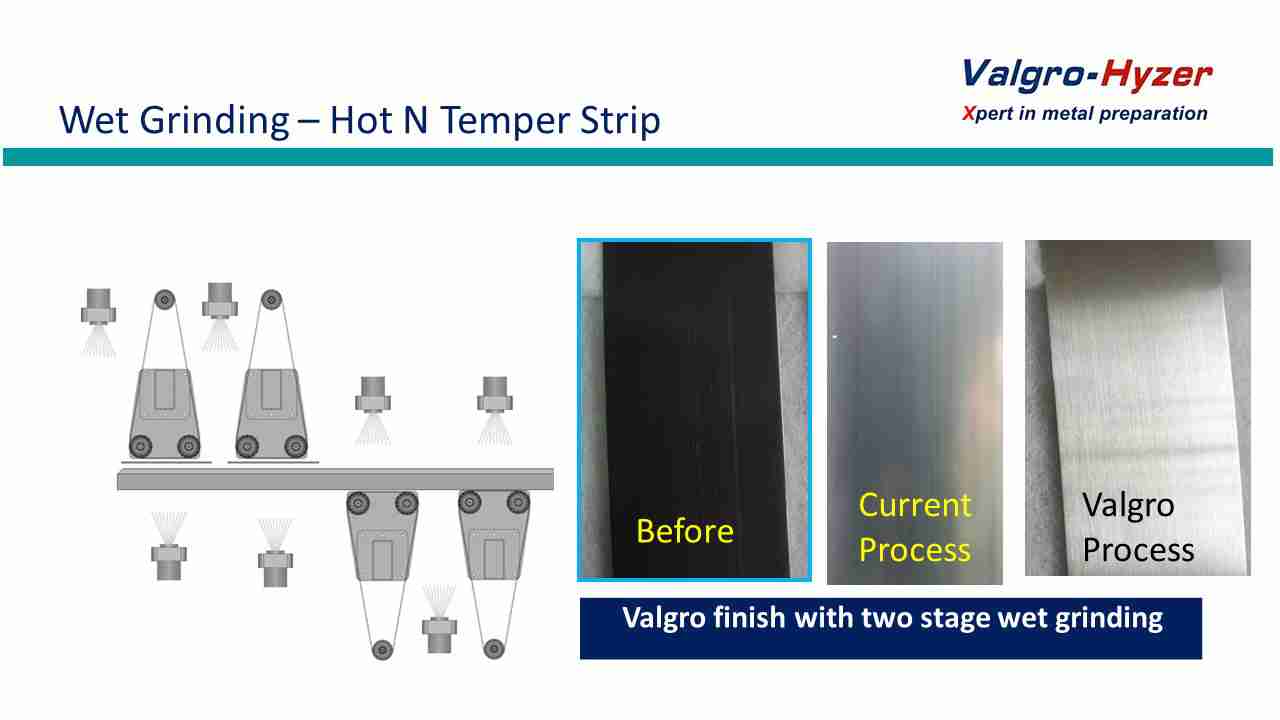

- Heavy Duty Grinding Machines need coolant to cool and lubricate the grinding process and to remove the sludge from the grinding cabin.

- Emulsion or Grinding Oil have been developed specially for this process and they are well proved to enhance the life-time of the grinding belts.

- Valgro India has designed and continuously developed wet type belt grinding machines, which work reliable in the rough environment.

Benefits :

- Vibration free uniform surface

- Consistent result from 1st meters to last running meters

- No strip Deformation – No Camber

- Cool running – Smooth running

- Less then 80 DB noise level at brushing machine

- Reduce power consumption – energy saving

- Increase Profit – Reduce Polishing cost

- Supper bright Finish

- Environment free polishing work

Hot N Tamper Strip Polishing brush Line : Wet Grinding

- Cleaning and Activating of strip surface before roll cladding

- Removal of loose scale on strip surfaces

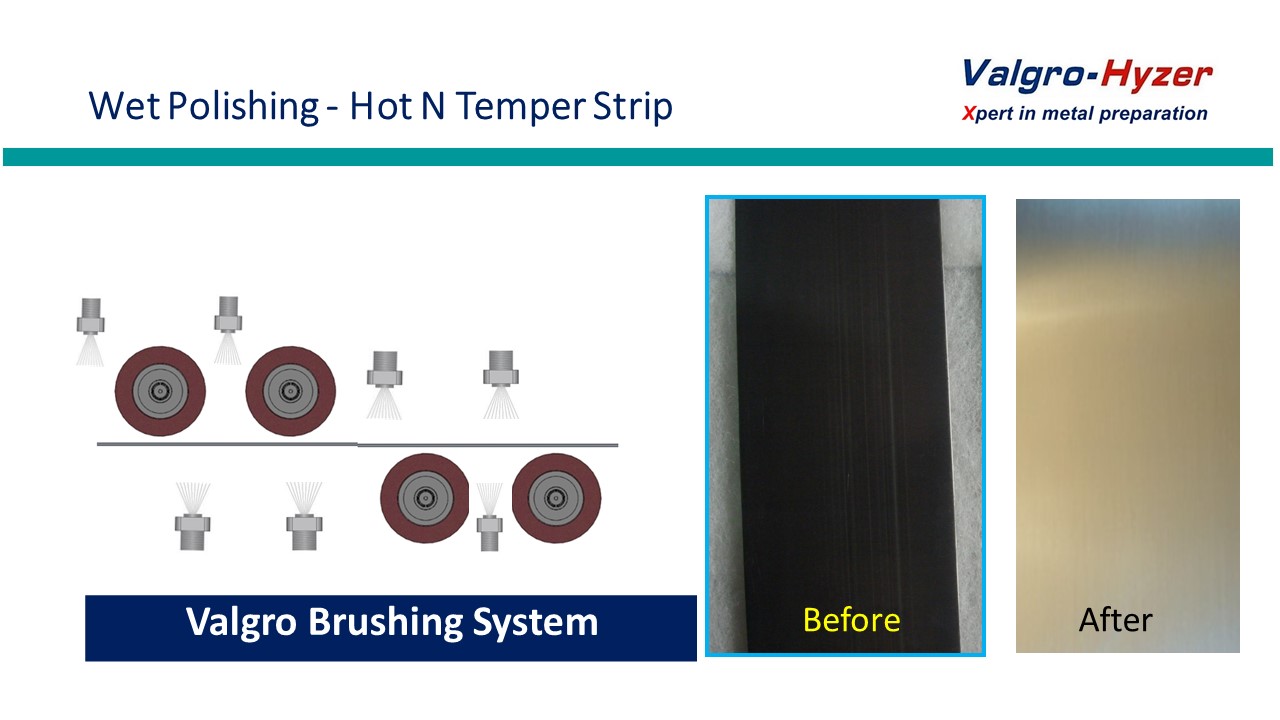

- Removal of annealing colours and minor defects by wet brushing

- Polishing is used to remove the damage remaining from the previous steps.

- This is achieved with steps of successively finer abrasive particles.