When plating copper bus bars with silver, a minimum of 3 microns and preferably 6 microns should be utilised. In addition, an anti-tarnish treatment would be required to safeguard the finish. Tin is suited for most permanent bus bar applications. Silver should be used to move bus bar components if arcing is a concern.

Anti-tarnish is necessary for both tin and silver plating to maintain the surface clean and conductive. Working with copper bus bars requires coating not just for longevity, but also for integrity and safety.

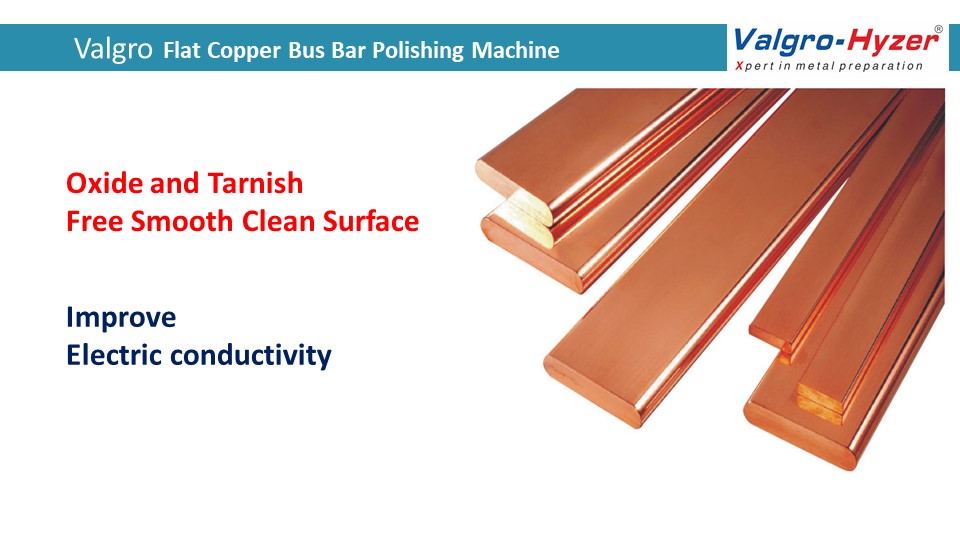

Oxide and Tarnish Free Smooth Clean Surface

Improve Electric conductivity

Features:

- Plug N Play machine

- Operated by any unskilled labour

- Maintains free system (0 maintenance)

- Rust resistance treatment for main body part

- Stress relieved main body & structure

- Buy back facility for Indian market / Good resale value products

- Vertical axis rotating and oscillating brushes

- Adjustable brushing pressure from panel

- consistent brush abrasion

- Solid metal body construction

- Different brush grits combinations are possible to perform different surface treatment

- emergency security switch

- All electrical motors can be switched on and off separately.

Technical Specification

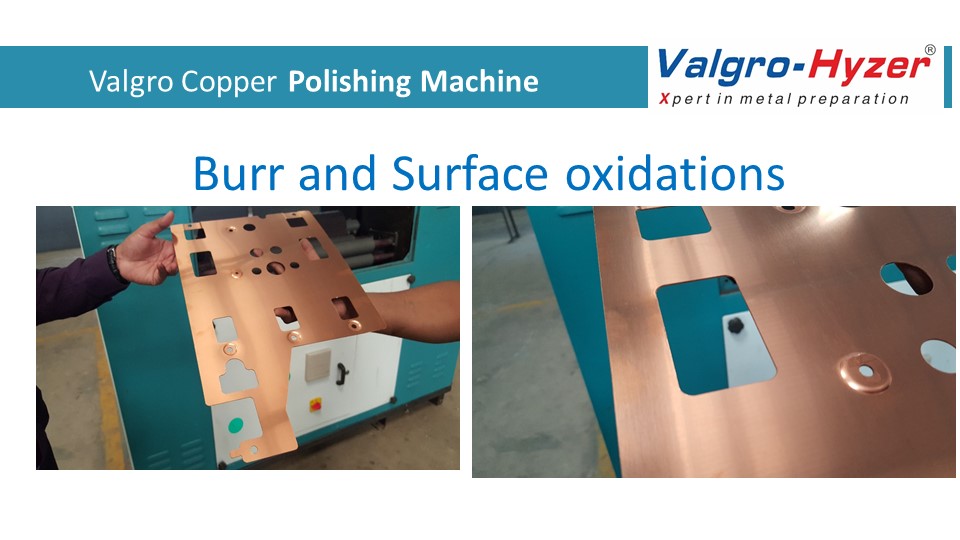

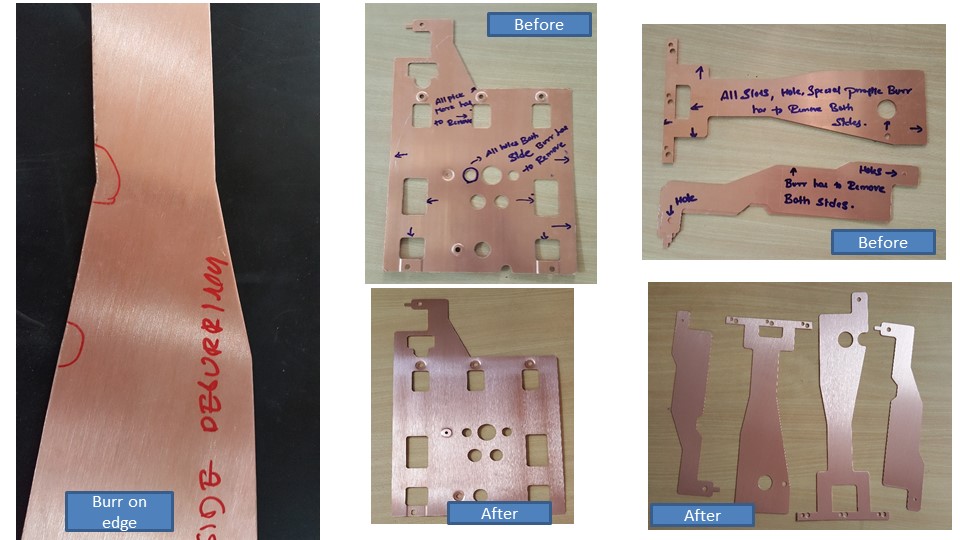

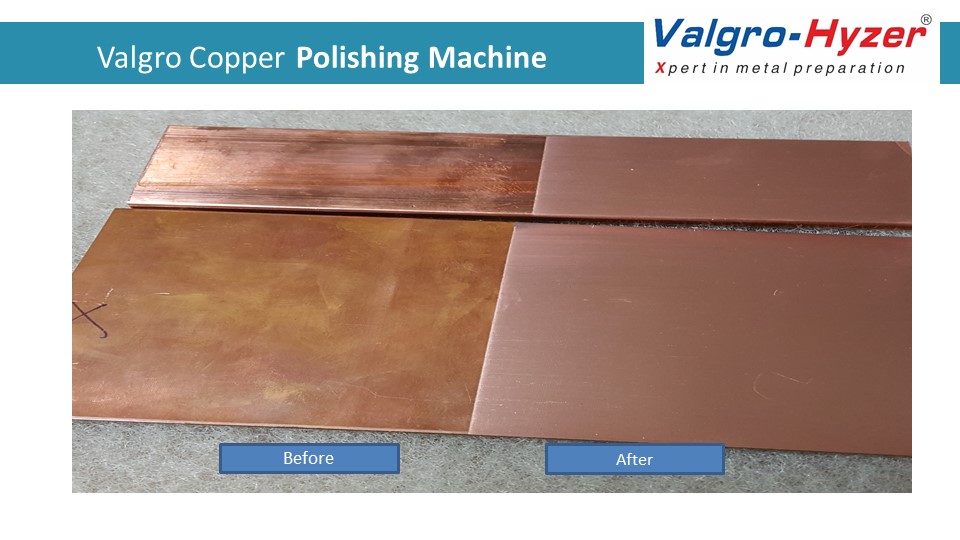

Oxide and Tarnish Free Smooth Clean Surface:

Electrical Panel builders

Bus bar producer

Transmission and transformer Industries