Valgro Coil / Strip grinding, and polishing machines designed for “wet” activities include a coolant recycling mechanism built into the machine. The used coolant, known as “swarf,” is collected at the bottom of the grinding heads and sent to a collecting system, where it is filtered to remove any metal particulates and then returned to the system as a clean coolant.

Heavy construction made of welded steel and spinning elements that have been dynamically balanced provides precise work that is not subject to vibration. Processing may be done simultaneously on either one side or both sides using a single head or several heads.

Valgro grinding and polishing lines are known all over the world for being reliable, sturdy, and easy to use.

The abrasive belt used in Valgro grinding and polishing systems are made for corrective grinding and/or finishing.

Applications, grinding “dry,” or with a flood of coolant on ferrous or non-ferrous alloys.

- Multi-head grinding station with 4 or 6 heads

- Standard or custom-designed systems, with single or multiple heads,

- Wet polishing line

- Oil and water mixed, wet type processing

- Adjustable Pressure on Polishing station

- Easy abrasives belt replacement

- Adjustable conveyor feed speed (Belt / Roller)

- Control by PLC with Touch Screen (Optional).

- Sturdy and latest technological System

- External Electrical Control Panel

- Separate electrical control for all functions

- Adjustable conveyor speed (belt/roller) from) o.5 to 20 MPM

- Emergency security switch

- Width Capacities: 18” thru 84” (457 thru 2134 mm)

- Spindle Drive: 20 thru 300 H.P. (15 thru 225 kW)

- Line Tension: Up to 144,000 lbs. (65, 318 kg)

Applications range from finishing decorative stainless steel to surface conditioning of titanium strips for industrial military use.

- Corrective grinding of ferrous and non-ferrous hot-rolled strip prior to cold rolling

- Polishing stainless steel to No.3 and No.4 Commercial Finishes

- Producing “hairline” finishes

- Surface preparation prior to bonding of bimetals

- Cross-sectional shape correction

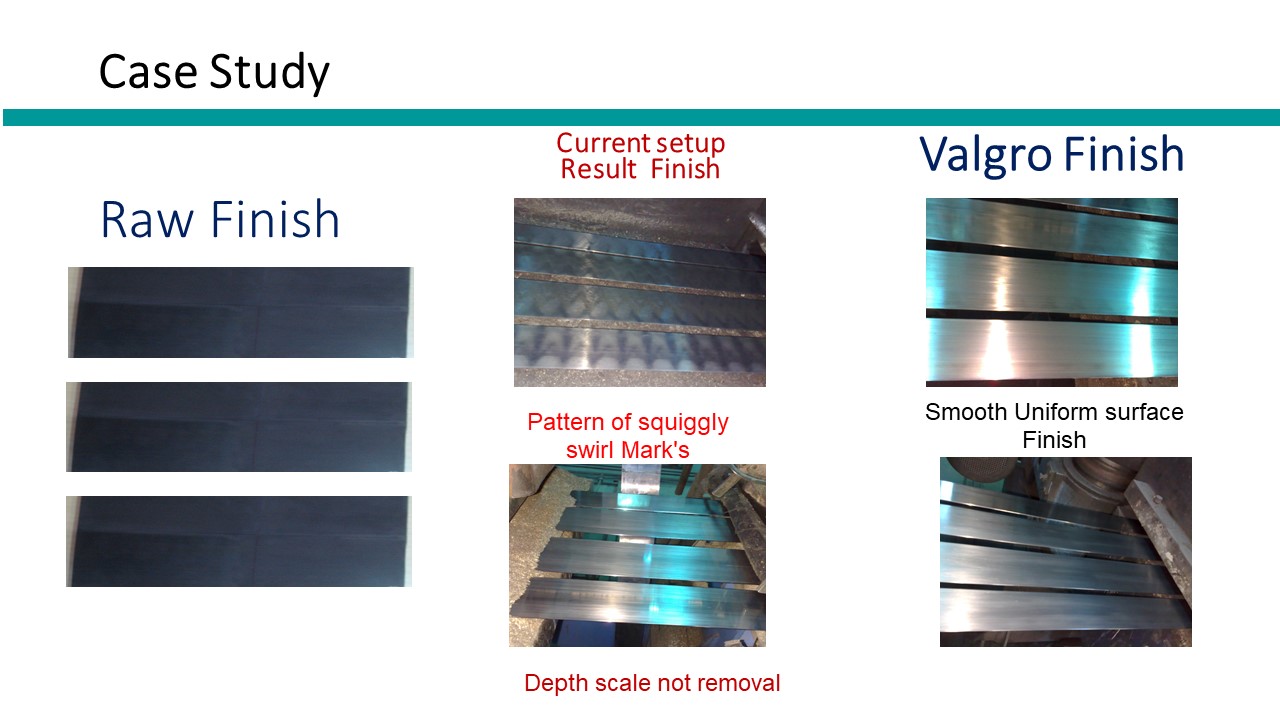

- Scale and surface oxide removal