Parameters to consider when choosing a Polishing Machine

Under the premise of meeting the requirements of various aspects, the polishing machine should also consider the following requirements.

- Design: The design of Machines, when done scientifically delivers Machines & results that not just meet but exceed the Performance parameters. Generally, the Factor of Safety is taken into consideration while designing moving parts & Machine elements working under loads. A good design also takes care of – Ease of Installation, Repairs & any adjustments. A good design eliminates or minimizes breakdown (ie) Increases Availability, thus improving productivity.

- Structure: Modular, Rigid with a good frame building. Welded Joints must be full & clean. Care should be taken during the designing stage to accommodate the future need for accessories onto the structure. The Structure also must be tested for its Mechanical processes.

- Material of Construction: Right selection of material for Machine parts that improve Quality of performance & Aesthetics, Light Weight to work with & ergonomically designed for ease of Operations.

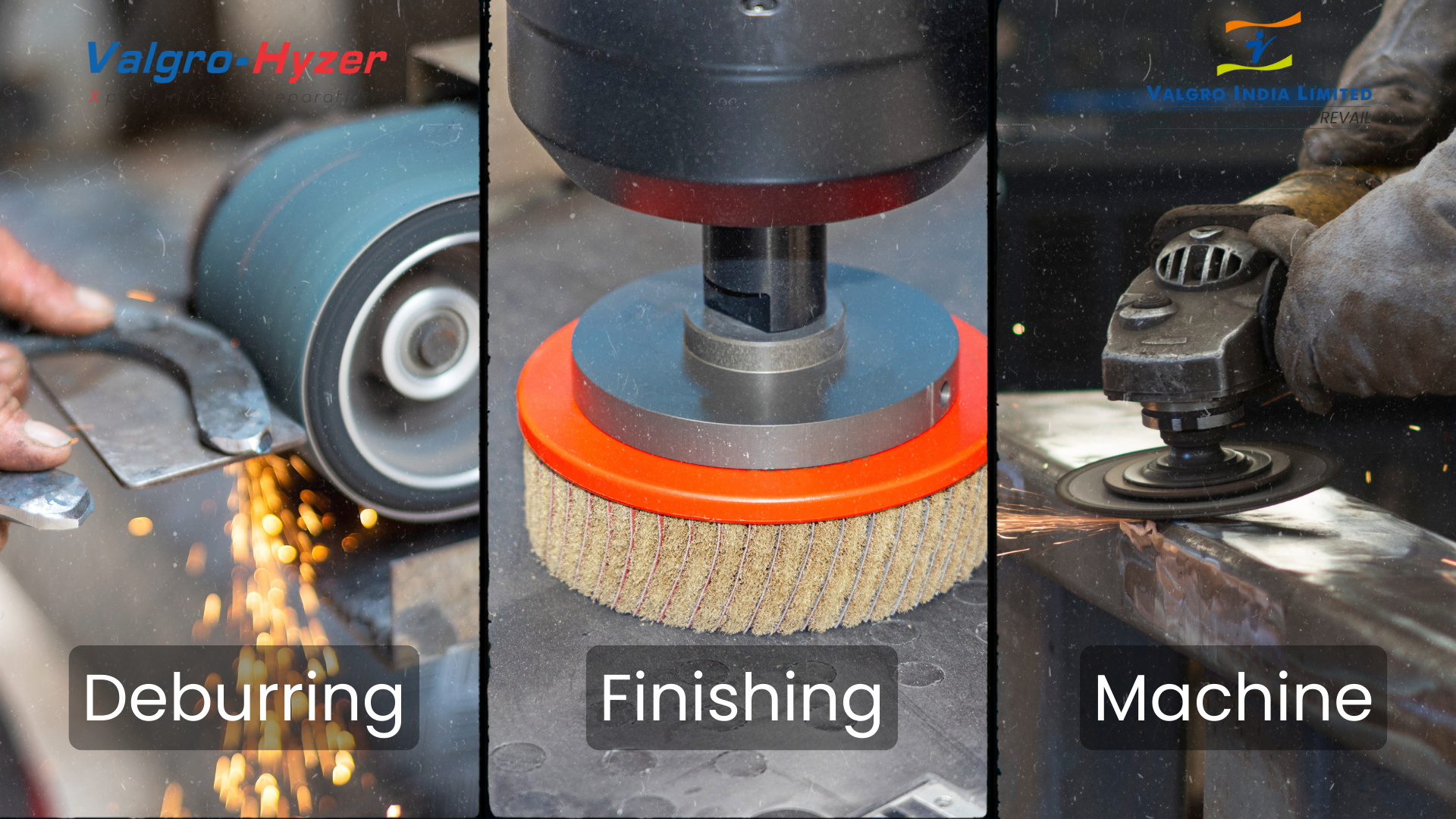

- Machine: Parts & sub-assemblies, when assembled to deliver the desired performance makes a Machine. The craftsmanship and the workability further enhance its purpose. The Polishing machine generally has a big structure and hence the importance of a good Machine.

- Transportation: The Polishing machine, due to its sheer size makes Transportation a challenge. The design should consider Safety & Health hazards involved during Transportation. Similarly, during Installation at the Site. The super-long and super-large polishing machine can be divided into several parts for manufacturing, transportation & installation. They are connected using an exploratory or captive connection.