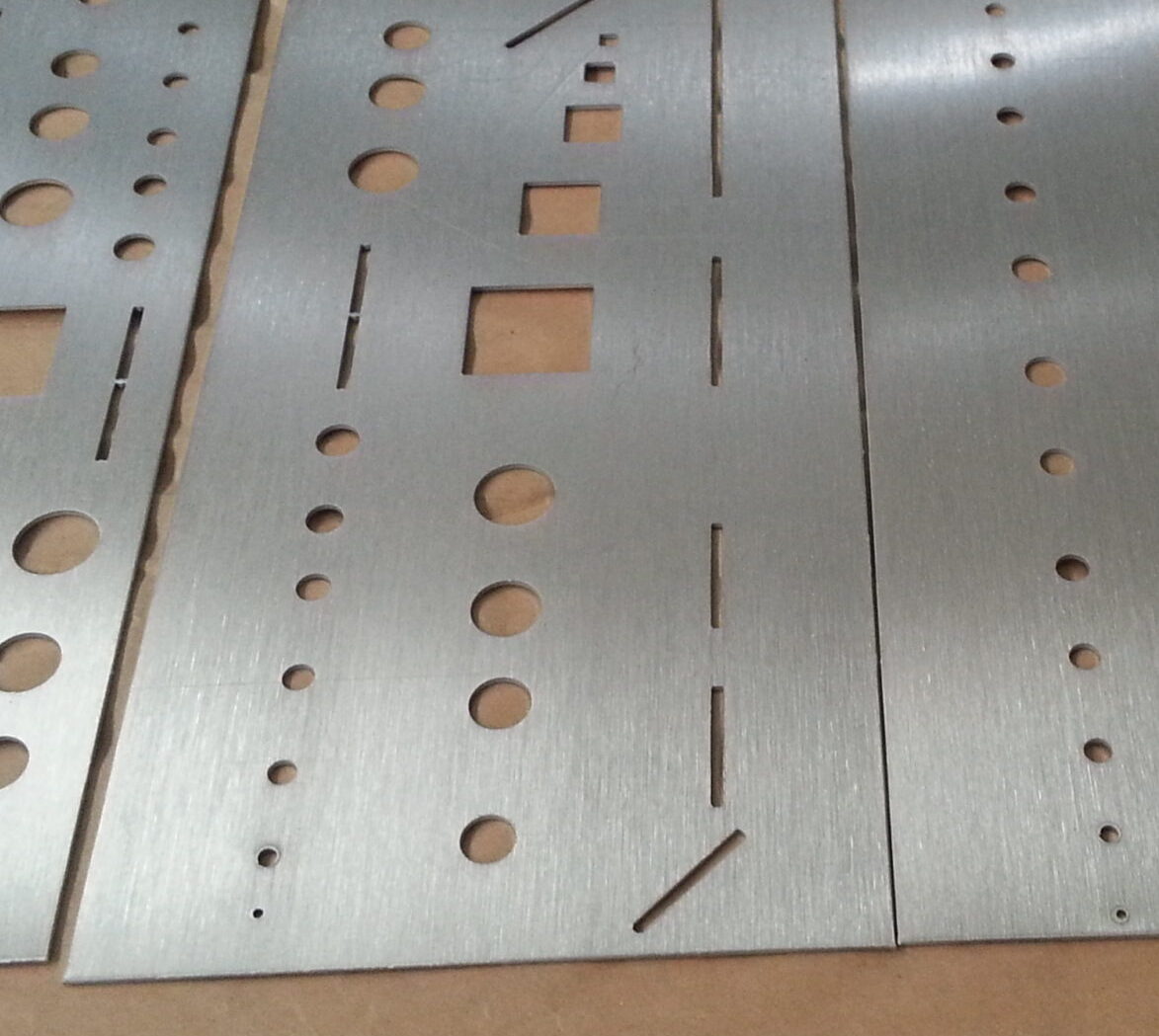

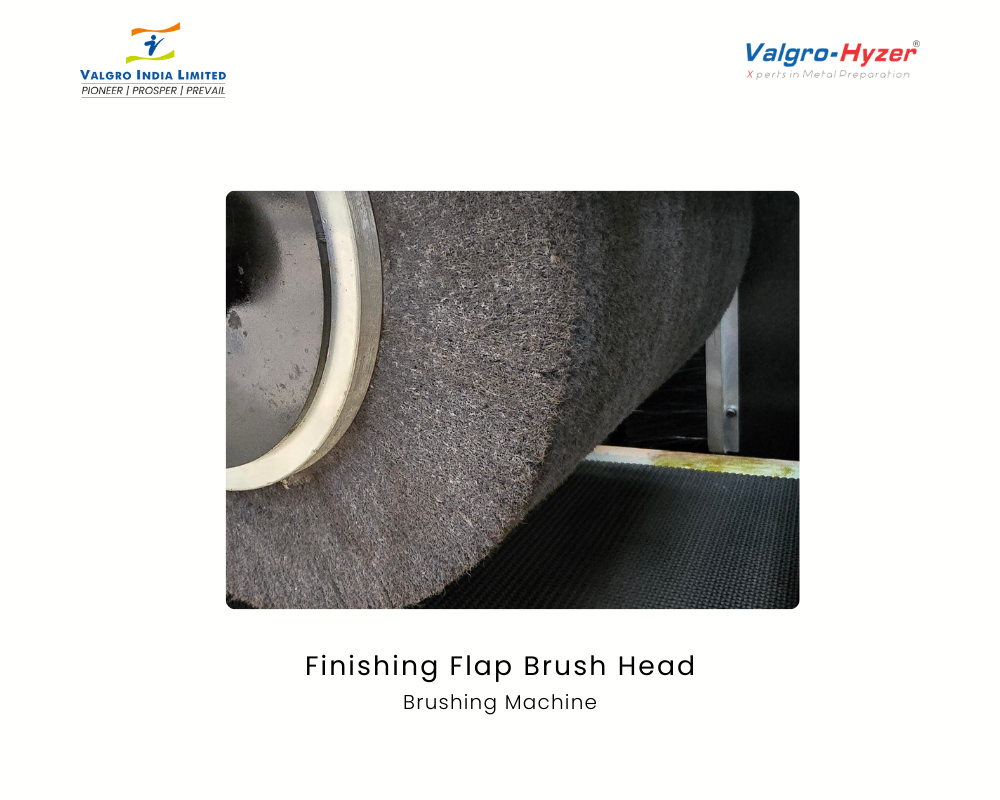

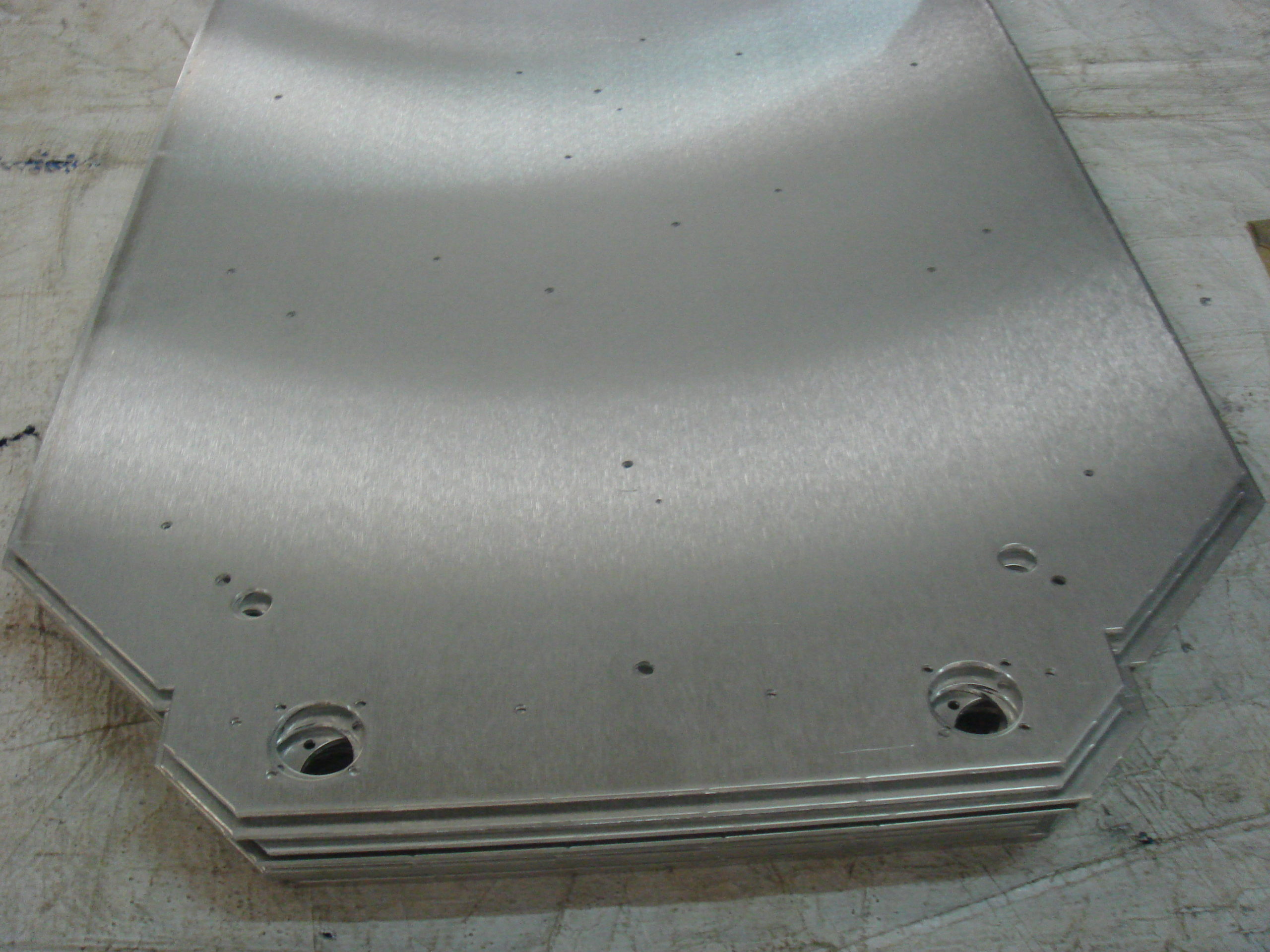

It removes microscopic scratches, acid coatings, and oxide from the metal sheets’ surface. The Valgro brushing and deburring machine is safer and more efficient than a traditional deburring system, and it may eliminate human deburring work. Valgro has developed many sheet deburring models to increase flexibility and save costs.

Benefits:

- The thin part can be deburring

- No heat generation, no deformation

- Faster production – saving time

- Clean and Green environment

- Low Space requirement

- Save money

- Reduce labor and workforce costs

- Multiple thicknesses from 0.8 mm to 3 mm.

- Suitable for different metals like SS, zinc, and aluminum.

- Eco-friendly process.

- Reduce labor and operational costs.

- Contactless handling to avoid scratches.

- Can be integrated into the current production process.

- Deburr of small and large parts together.

- Compact design for small space units.

- Simple and easy consumable replacement.

- Robust and precise system.

- Emergency security switch.

- Built with all safety standards in mind

Technical Specification

Valgro SAMARTH Fabrika series Sheet Deburring machine is widely accepted at sheet metal fabrication Industries

- Kitchen Equipment Mfg.

- Dairies and Breweries Process machinery Mfg.

- Pharma & Food Process Machinery Mfg.

- Architect and Building construction (A.B.C. Sector)

- Lift and elevator manufacturer.

- Stainless Steel Tube, Rod, and Flat bar user, Mfg.

- Automobiles & Public Transport

- Railways

- Instrumentation