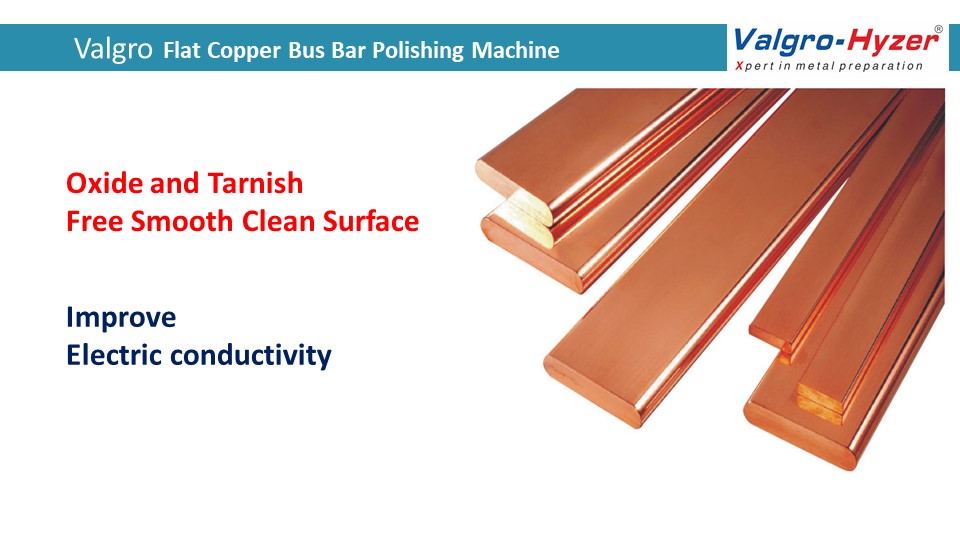

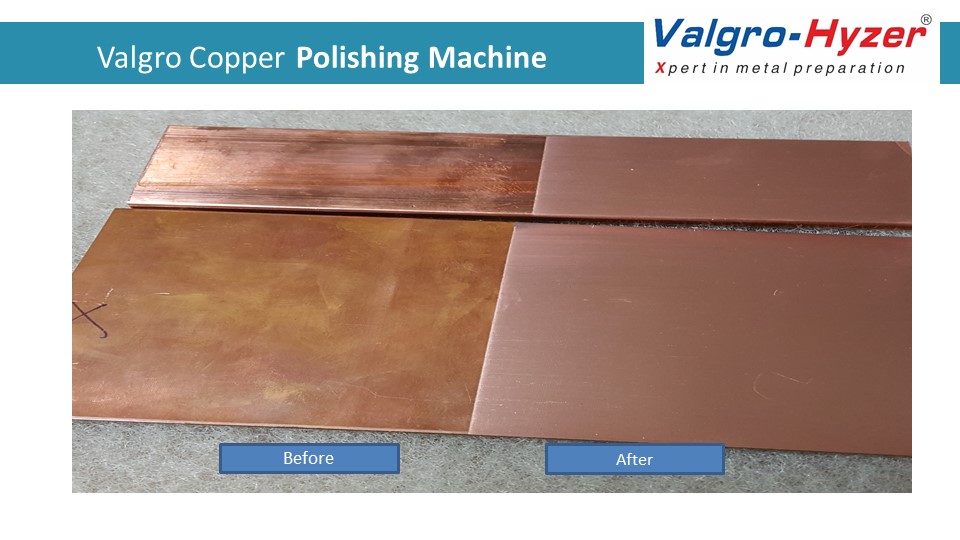

Reasons for a Finished and Tarnish-Free Surface:

- Electrical Conductivity: Tarnish and oxidation on the surface of bus bars can increase electrical resistance, leading to energy loss and reduced efficiency in electrical systems. A clean, finished surface ensures optimal conductivity and reduces power losses.

- Corrosion Resistance: Tarnished surfaces are more prone to corrosion, especially in environments with high humidity or chemical exposure. A finished surface acts as a protective barrier against corrosion, extending the lifespan of the bus bars.

- Reliability: Tarnish and oxidation can create irregularities on the surface that may affect the reliability of electrical connections. A smooth, tarnish-free surface ensures consistent electrical performance and reduces the risk of intermittent faults or failures.

- Aesthetic Appeal: In applications where bus bars are visible or accessible, such as in electrical panels or equipment cabinets, a clean, finished surface enhances the overall appearance. It reflects quality craftsmanship and attention to detail.

- Ease of Maintenance: Finished surfaces are easier to clean and maintain. They resist dirt and grime buildup, reducing the frequency and effort required for maintenance tasks.

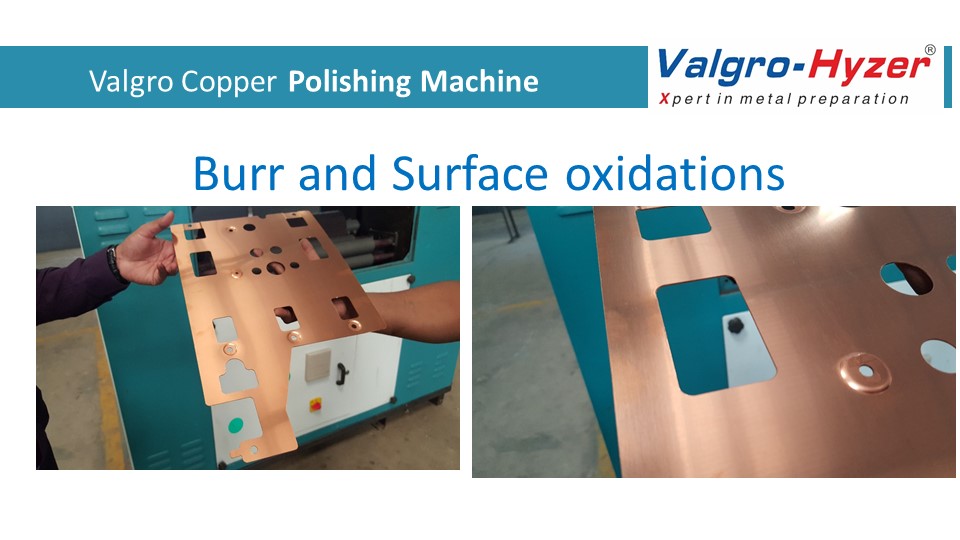

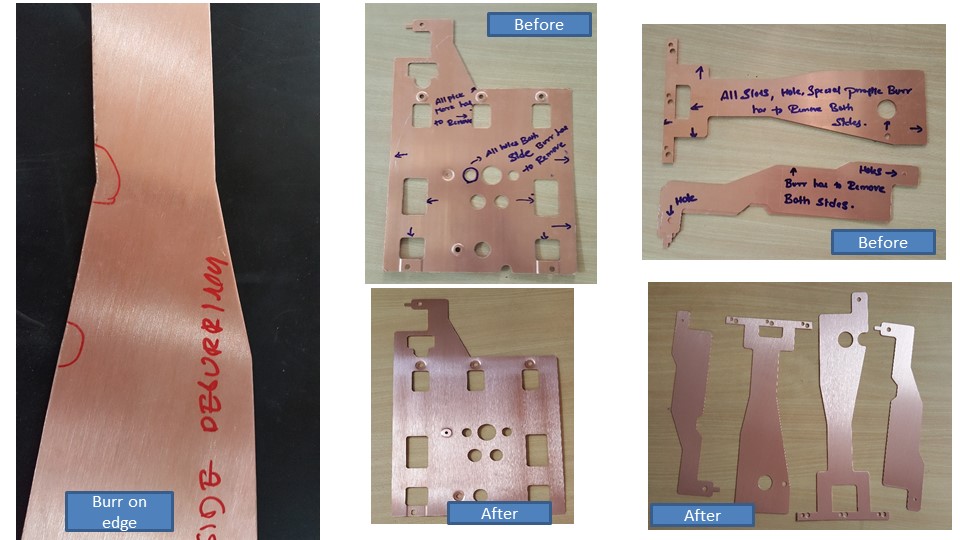

- Advanced Burr Removal Technology:

- Emphasize the machine’s capability to efficiently remove burrs left after punching, ensuring a smooth and clean surface.

- Customizable Finishing Options:

- Highlight the machine’s flexibility in offering various finishing options, such as brushing, polishing, and deburring, tailored to different bus bar sizes and materials.

- High precision and consistency:

- Showcase how the machine delivers precise and consistent results, maintaining uniformity across all bus bar surfaces.

- Enhanced electrical conductivity:

- Explain how the machine improves electrical conductivity by eliminating surface imperfections, reducing resistance, and minimizing energy losses.

- User-Friendly Interface and Automation:

- Mention any automation features or user-friendly interfaces that simplify operation and increase productivity.

- Durability and Reliability:

- Highlight the robust construction and reliability of the machine, ensuring long-term performance and minimal maintenance.

- Compliance with Industry Standards:

- Assure customers that the machine meets or exceeds relevant industry standards for electrical safety and performance.

- Energy Efficiency and Cost Savings:

- Illustrate how using the machine contributes to energy efficiency, resulting in cost savings over time due to reduced power losses

Technical Specification

- Electrical Manufacturing: Used in the production of switchgear, control panels, and other electrical components where bus bars are essential for power distribution.

- Renewable Energy: Critical in solar and wind power installations where efficient energy transmission is crucial for overall system performance.

- Industrial Applications: Found in various industrial settings where reliable electrical connections are vital for uninterrupted operations.