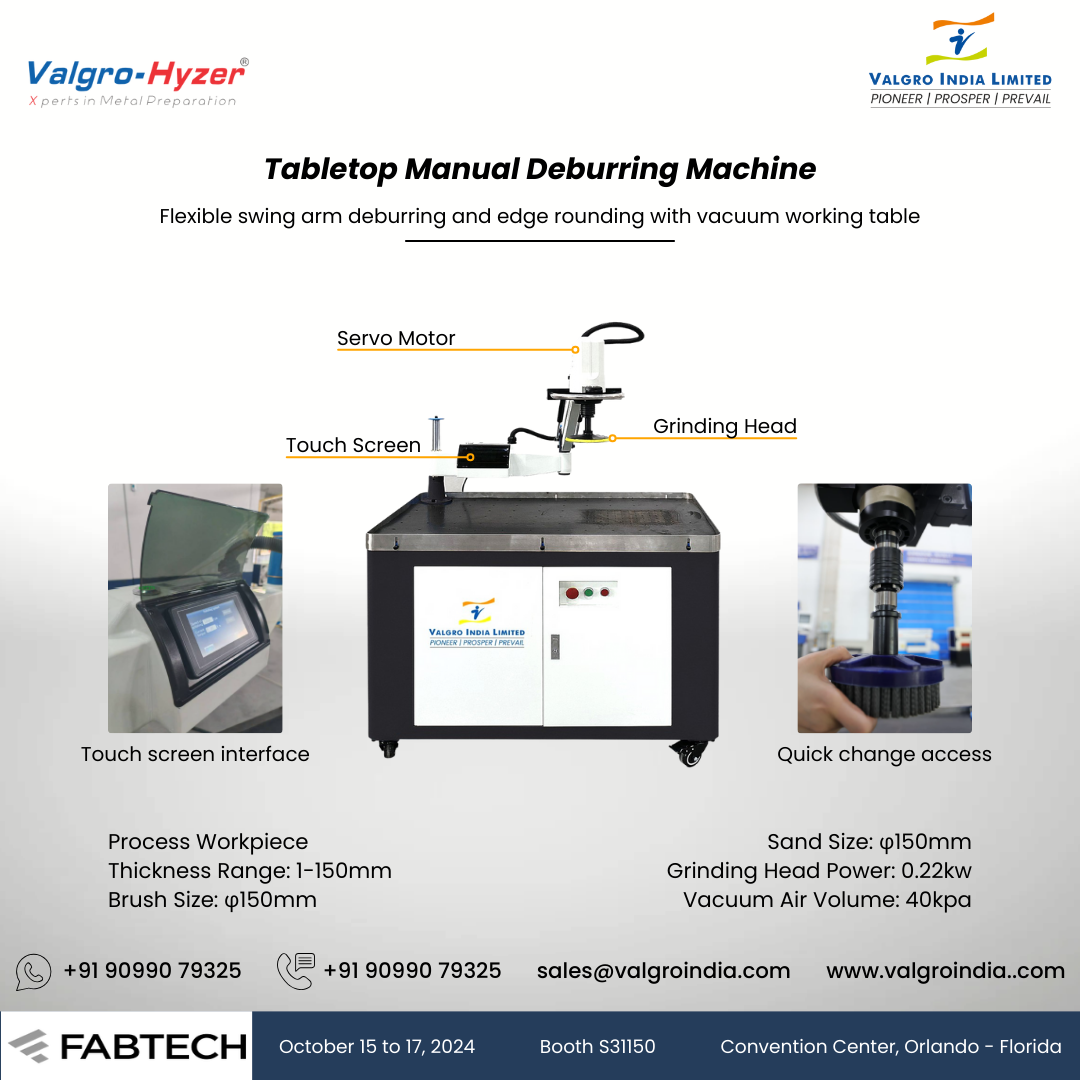

Tabletop Metal Edge Deburring & Rounding Machine with Vacuum Table | Valgro Efficient Solution

Experience the future of metal finishing with our latest third-generation manual deburring machine. Designed for simplicity and efficiency, this innovative tool is perfect for deburring and chamfering flat metal plates across a wide range of materials with thicknesses from 1 to 150 mm.

The Valgro Table Top Deburring Machine provides an effective and reliable solution for achieving high-quality metal finishes in smaller production environments. Its user-friendly design and versatile features make it an essential tool for professionals seeking precision and efficiency in their deburring operations.

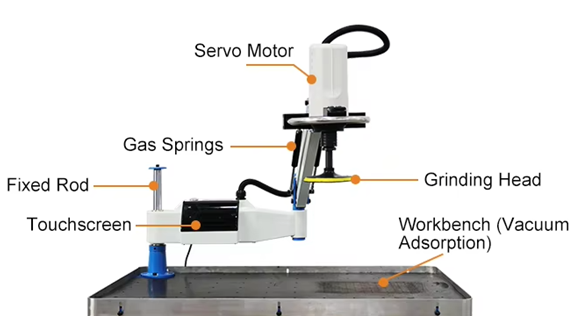

- Adjustable Speed: Customize the machine’s speed to meet the specific requirements of different deburring tasks, offering flexibility for diverse applications.

- Vacuum Clamping Table: Features a hole-patterned vacuum clamping table that securely holds workpieces, enhancing stability and accuracy during operation.

- Safety Controls: Equipped with a 2-button control system that ensures safe and straightforward operation, minimizing risks and promoting user safety.

- Balance Arm: The balance arm design provides stability and ease of use, allowing for precise and vibration-free deburring and edge-breaking with minimal physical effort.

- Tool Exchange and Adapters: Includes an intake for easy tool changes and is compatible with various adapters, making it a versatile choice for different deburring needs.

- three to four times faster than manual deburring

- Easy-to-use with swinging arm and weight compensation

- High friction table cover, dust drawer and extraction outlet

- Rotatable head with deburring and edge rounding tools

- Numerous safety features including automatic motor shutdown when head is tilted and pneumatic brakes for swinging arm

- For laser-cut, plasma-cut and punched parts

- Processing of foil-covered or zinc-plated parts

- Processing of steel, stainless steel and aluminium

1. The servo motor controls the speed, with high-speed

2. CNC system integration

3. The operator lifts the cantilever with one hand and only needs to press down lightly to achieve the required

grinding force and complete the grinding process, which greatly saves manpower.

Process Workpiece Thickness Range: 1-150mm

Brush Size: φ150mm

Sand Size: φ150mm

Grinding Head Power: 0.22kw

Vacuum Air Volume: 40kpa

Total Power 3.8kw

Machine size 1100*710*1240mm

Machine weight 169kg

Package size 1210*790*1270mm

Package weight 205kg

- Edge Preparation: Ideal for preparing edges for coating or further processing by creating smooth, clean finishes.

- Metal Fabrication: Suitable for small-scale metalworking tasks, including edge-breaking and deburring of components.

- Prototyping and Small-Batch Production: Well-suited for prototype development and small-batch production runs, offering efficiency and flexibility in metal finishing.