What types of metal parts are commonly processed using deburring and finishing machines?

Introduction In the field of metal manufacturing, the ultimate quality and functioning of metal products are critical. Deburring and finishing equipment are crucial to ensuring that these components satisfy industry requirements. This article delves into the diverse range of metal components routinely processed by deburring and finishing equipment, emphasizing the importance of these procedures across various industries.

How do Deburring and Finishing Processes Improve the Quality of Metal Parts?

Introduction: Metal fabrication includes many techniques for shaping, cutting, and assembling metal components. However, the true measure of a component's greatness is its manufacture and the meticulous finishing touches that come after that. Deburring and finishing are important steps in producing high-quality metal components that meet safety, operational, and aesthetic standards. This article describes how several strategies may enhance the overall quality of metal components.

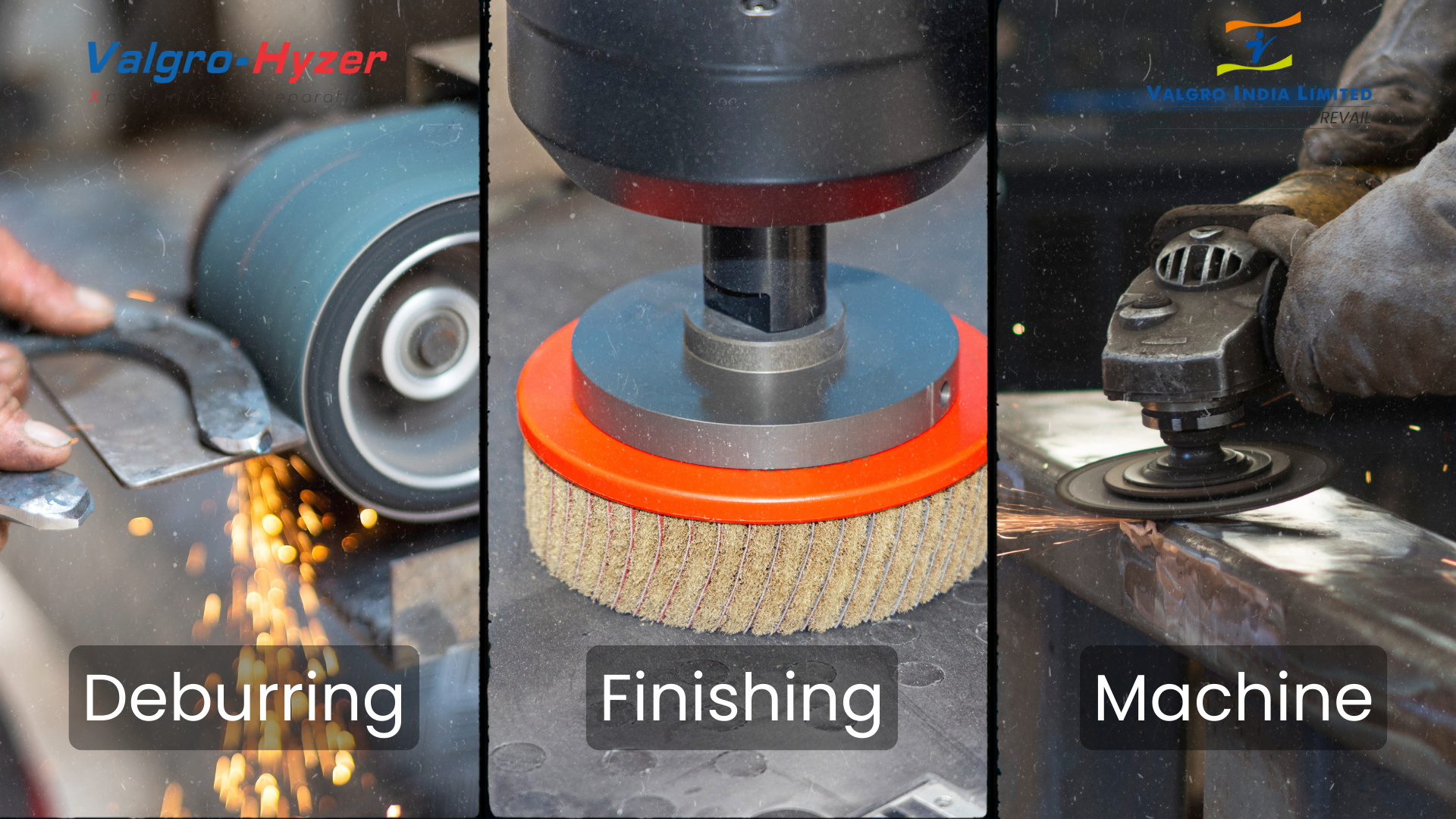

The Primary Purpose of Using Deburring and Finishing Machines in Metal Fabrication?

Background on Metal Fabrication: Metal manufacturing requires the greatest quality and usefulness of #metal products. This method relies heavily on #deburring and #finishing equipment. This article delves into the main function of these machines and their influence on metal manufacturing. Metal fabrication includes a variety of operations, including cutting, drilling, milling, and stamping, to make metal parts and components. Although these procedures are necessary for shaping metal, they often leave behind flaws such as sharp edges, ridges, and burrs. Imperfections may impact the end product's performance, safety, and aesthetics.

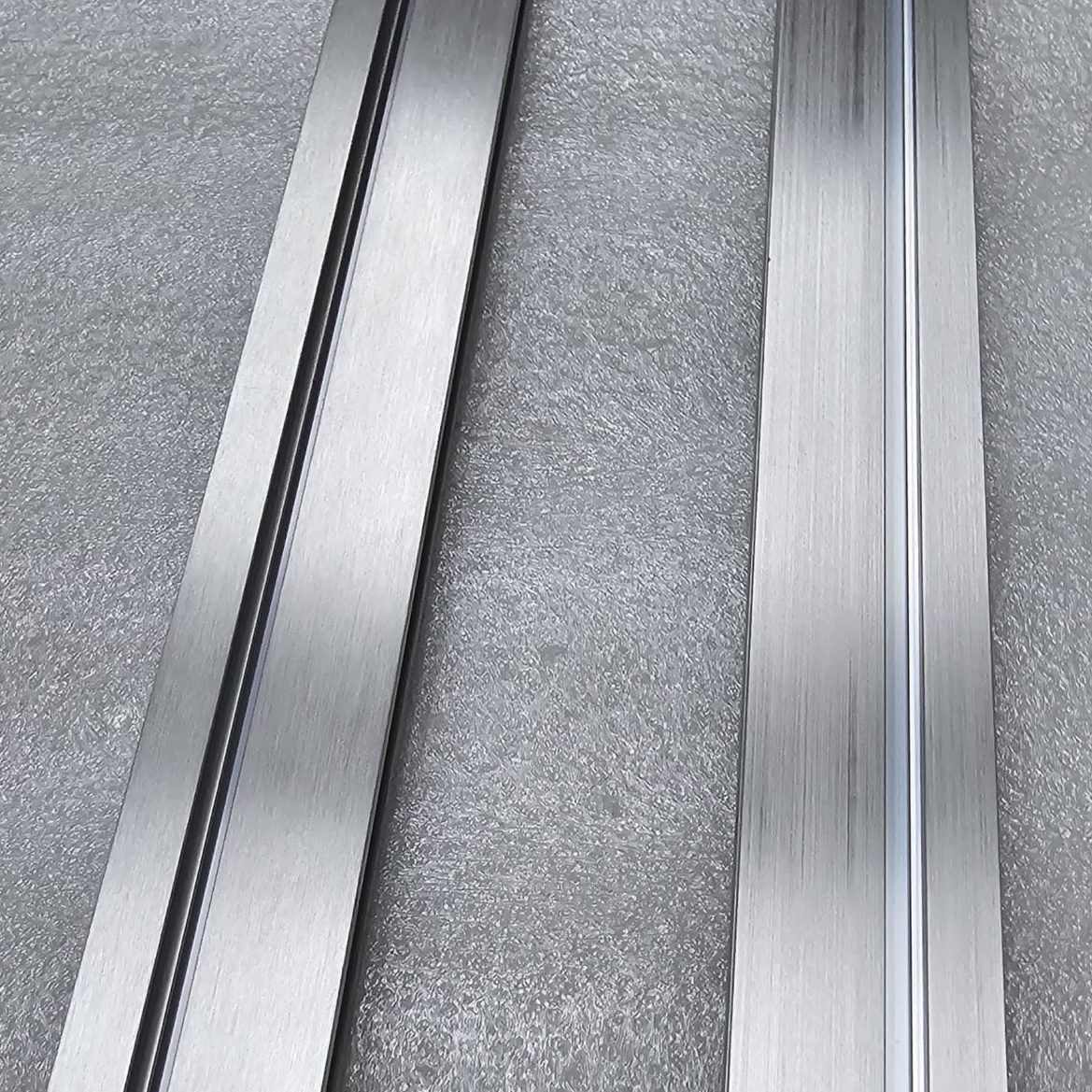

Why Aluminum Profiles Need Brush Finish and How Valgro India Can Help?

Aluminum profiles are widely used in various industries due to their lightweight, durability, and corrosion resistance. However, to achieve the desired aesthetic appeal and functional properties, a brush finish is often applied. Here’s why a brush finish is essential and how Valgro India can assist with their expertise:

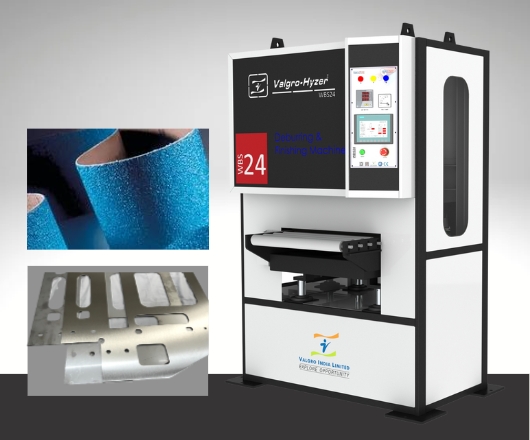

Why is expert advice required when purchasing a deburring and Metal Finishing machine for Sheet metal working?

expert advice may be required when purchasing a deburring machine for sheet metal working to ensure that the purchaser makes the best possible decision and that the purchase aligns with their needs and objectives. The expert can provide valuable insights and guidance throughout the selection and purchasing processes, helping to ensure that the final decision is the right one.

Dr. Arvind Patel is a True Leadership Example in Industries

Many organizations make basic errors throughout the finishing and deburring process that end up costing them a lot of money. The following are some of the most common errors.

Common Mistakes – Deburring and metal finishing process selection

Many organizations make basic errors throughout the finishing and deburring process that end up costing them a lot of money. The following are some of the most common errors.

Deburring machines: how to choose the best one for your process?

Deburring is a key procedure in every manufacturing business. With the availability of cutting-edge technology, quality standards have also gotten more severe. Machining techniques such as shaping, fine blanking, cutting, milling, and punching...............