Burr removal on thick parts is Headache after laser cut

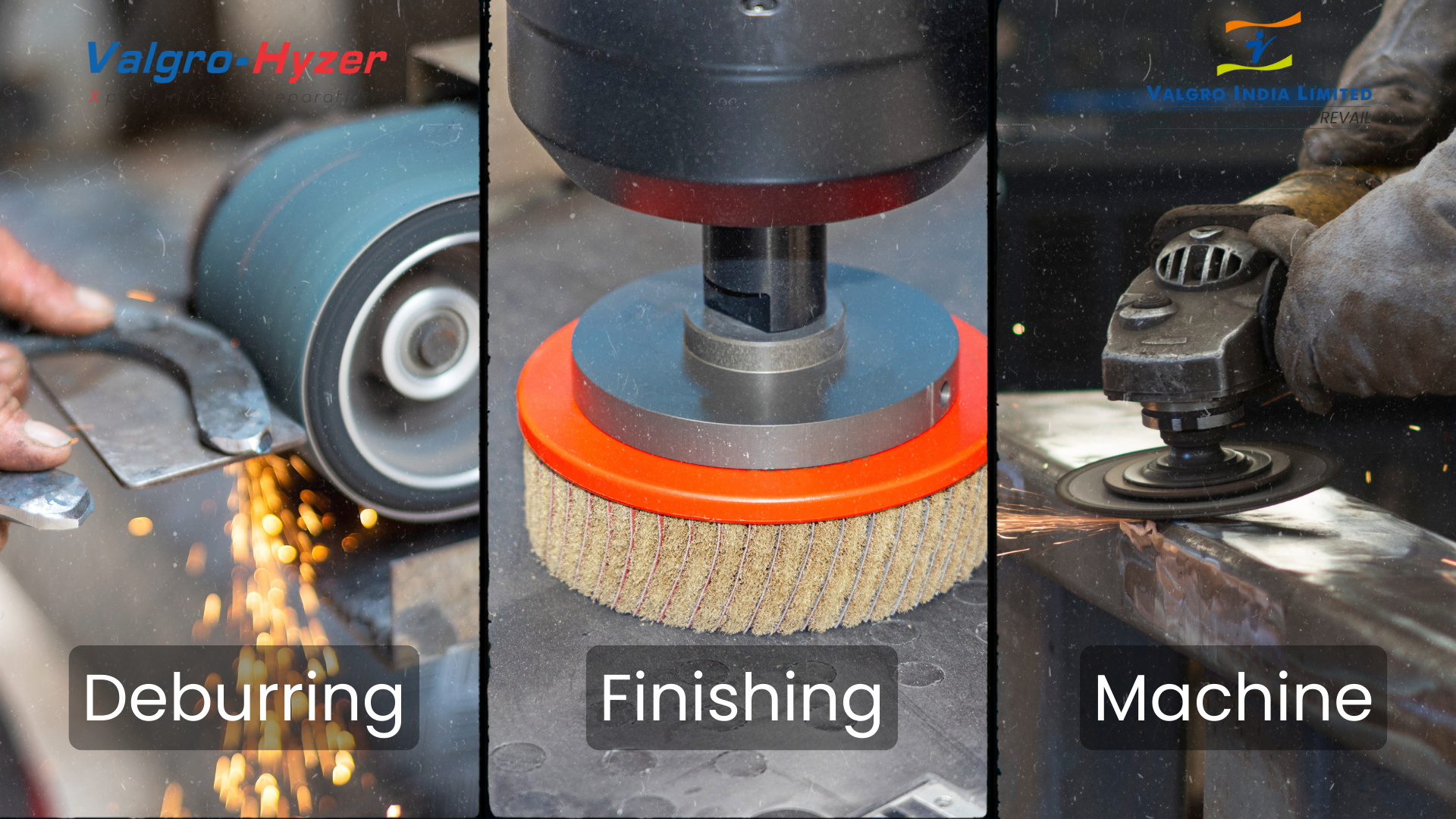

Our surface preparation abrasives brush manufacturing experience has allowed us to build a successfull model LBF KARAM Deburring + Edge Rounding machine with all the necessary technical devices required to obtain a perfect finish from small parts to a larger area.

Most of the manufacturing & fabrication processes produce undesired Burr. As industry is striving for high speed, highly productive and efficient machines, the components going in these machines need to be highly precise. Residual burr in such assemblies may result in malfunctioning of machine which in-turn would result in a loss in productivity and efficiency. Deburring process ensures removal of even minute secondary burr from the component which results in smooth & extended product life. Deburring has over the years become a Critical Operation for Many components.

Valgro LBF KARAM Series deburring and Edge rounding machine available with two different variant, Cross Belt + Disc brush and Cross belt + High Flexible Roller brush,

Both model are very economic again any international brand, available with all safety standard. Reduce labour and increase productivity.

Advantages Compared to Traditional treatment

- Does not suffer under flying spark by manual operation.

- No physical strain to operator

- 60% time saving with faster operation.

- Improve work environment.

- Reduction of dust, dirt, and Noise