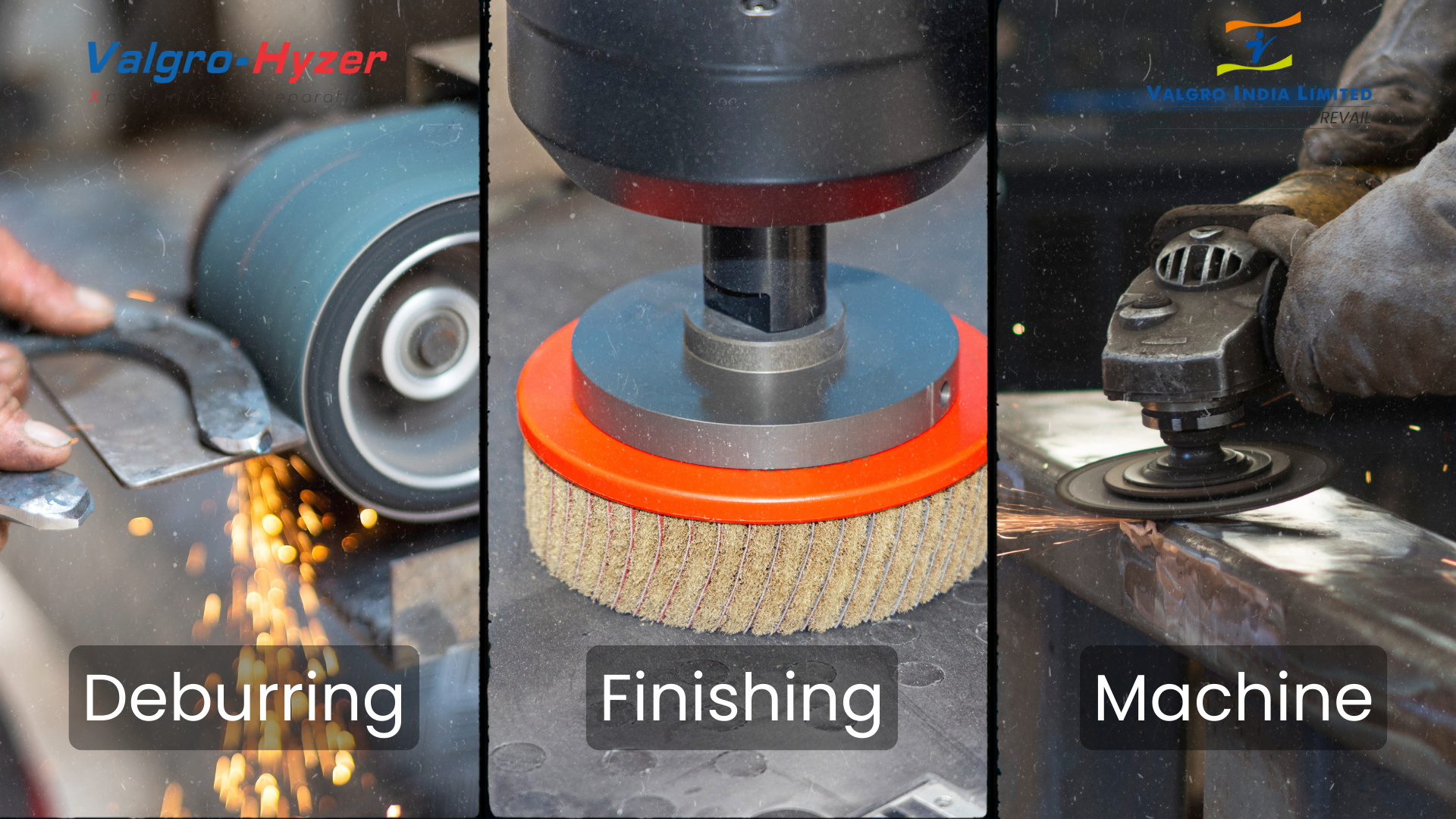

Deburring is a key procedure in every manufacturing business. With the availability of cutting-edge technology, quality standards have also gotten more severe. Machining techniques such as shaping, fine blanking, cutting, milling, and punching always produce sharp edges and burrs, which present problems in subsequent processes as well as safety concerns. As a result, it’s essential to remove them properly, and every machining firm should invest in a metal deburring equipment.

Due to the usage of conventional handheld deburring tools, industries are now grappling with burr removal operations. The availability of trained labor and constant burr removal with a clean edge radius is one of the most difficult difficulties in conventional techniques.

If you are considering purchasing a metal deburring equipment for the first time, you should be aware of certain important considerations.

This post will show how to choose the finest one for your situation.

Wet vs. Dry Deburring Machines- which one is suitable for you?

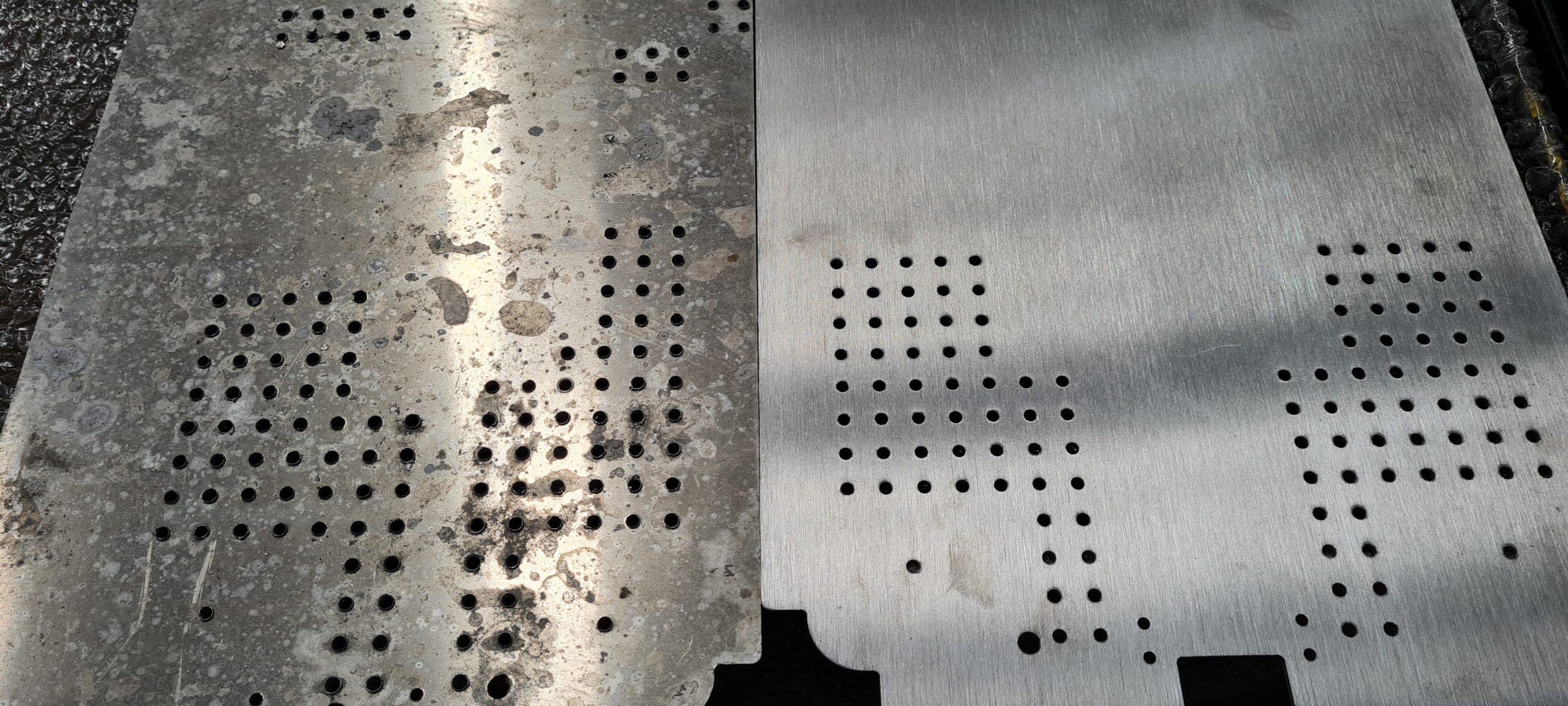

Metal deburring is classified into two types: wet and dry. A wet metal finishing machine is the best option if your organization works with materials with low melting points, such as aluminum and other soft metals, or if precise sheet metal components cannot be deformed. You may also choose a dry deburring machine for materials with a high melting point, such as carbon steel. However, if your organization works with both kinds of materials, make a list of the main metalworking techniques that your staff is familiar with. You must choose the appropriate deburring option based on your needs.

Production processes:

The deburring process’s needs vary greatly depending on the machining technique and metrology material. Laser or plasma cut surfaces, for example, need different surface finishing than punched or drilled surfaces. Another consideration is whether deburring should be done on one or both sides. Furthermore, the machine specs will differ depending on whether you want to deburr simply the vertical edges or all surfaces. Finally, recording your specific needs will assist you in selecting the ideal equipment.

Types of materials to be deburred:

Another important consideration when choosing the correct deburring equipment is the sort of components you will be producing. A crucial determining element is whether you want to remove big or little burrs or work with thin sheets or hefty plates. When selecting the correct machine, you must first understand your component matrix and edge needs.

Classifying burrs simplifies deburring machine selection:

Steel, aluminum, ductile iron, and titanium are just a few of the materials that may develop burrs after cutting process.

Class 1 burrs are referred to as “micro burrs” since they can only be seen under magnification.

Class 2 burrs are also little burrs that can be seen with the naked eye and are frequently referred to as “feather burrs.”

Class 3 burrs are little burrs that are firmly connected.

Class 4 burrs are huge and firmly connected burrs.

Class 5 burrs are often referred to as “extruded burrs,” however they are not burrs. They are caused by drilling on extruded material, which causes it to alter form.

Production capacity:

The machine specification is heavily influenced by the amount of work. Every business is concerned with production and efficiency. If your machine shop operates at full capacity 24 hours a day, you’ll need a machine that can handle huge volumes and requires minimal change-over time. You must evaluate your organization’s future expansion, which will need more output. Purchasing a machine is a CAPEX expenditure, thus the choice must be taken after considering the future, which must be adequately budgeted.

A trustworthy supplier:

It is critical to find the proper provider for your deburring solution throughout the purchase process. A reputable machine maker will not only provide a high-quality product, but will also provide appropriate solutions when needed. Furthermore, a reputable firm will always assist you with the necessary replacement parts to minimize downtime. When it comes to choosing the proper deburring machine provider, after-sales support is a crucial consideration. During the technical debate, you must keep the following items in mind.

- Spare parts availability

- Preventive Maintenance Offerings

- Installation and training

- Service and repair options

- And most important is Local Service support

Author :

Dr. Arvind Patel

Metal Finishing Expert

Founder and CEO – Valgro India Limited

sales@valgroindia.com