Discover Valgro’s Latest Innovation at FABTECH Chicago 2025!

Valgro India is proud to announce its participation at FABTECH Chicago Expo 2025, the most exciting and largest metal forming, fabricating, welding, and finishing event in North America!

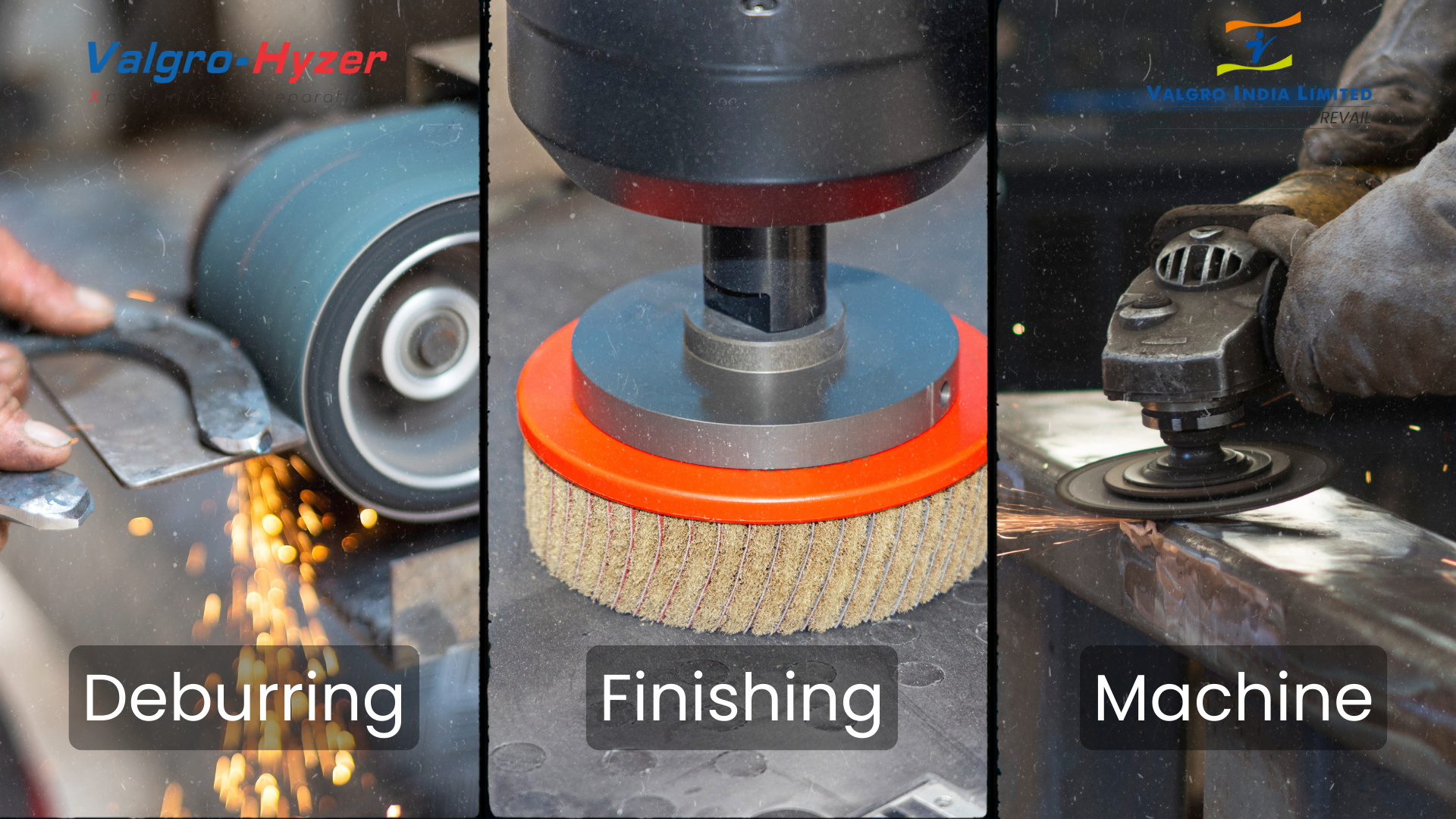

Get ready to experience the latest breakthroughs in deburring and surface finishing technology — built for the industries shaping tomorrow.

Introducing Two Game-Changing Solutions:

Valgro EZ-24 Series

The Ultimate Multi-Purpose Deburring and Finishing Machine

Designed for soft metals like Aluminum, Stainless Steel, Brass, and Copper, ideal for:

- Aerospace Components

- Satellite Systems

- Defense Equipment

- Precision Parts cut by Press Punch and Laser Cutting

Achieve superior surface finishing, edge rounding, and burr removal with unmatched efficiency — critical for the next-generation sunrise sectors driving global innovation.

Valgro SLR-24 Series

Heavy-Duty Deburring and Edge Breaking Machine

Built for Infrastructure and Heavy Engineering Applications, including:

- Earthmoving Equipment

- Road and Building Construction Parts

- Railway Components

Perfect for materials cut by Laser and Plasma Operations, the SLR-24 Series delivers robust performance for the toughest, heaviest parts — helping industries meet the highest standards of durability and safety.

Why Visit Valgro at FABTECH Chicago 2025?

🔹 See live demonstrations of the EZ-24 and SLR-24 series in action

🔹 Learn how advanced deburring and finishing can boost your productivity

🔹 Discuss your specific challenges with our expert team

🔹 Explore solutions for aerospace, defense, construction, railways, and more

🔹 Be part of the most vibrant metalworking and manufacturing network across USA and South America

FABTECH Chicago Expo 2025

Dates: 2025 – September 8-11

Location: McCormick Place, Chicago, USA

Valgro Booth: A4390

Join the Finishing Revolution with Valgro India!

Advance Your Manufacturing. Outperform the Competition.

Schedule Your Meeting Now | Get a Free Consultation at Our Booth

#FABTECH2025 #FABTECHExpo #FabricationTechnology #ValgroIndia #DeburringSolutions #EdgeRoundingMachines #SurfaceFinishingTechnology #MetalworkingInnovation #NextGenManufacturing #IndustrialExhibition #ValgroIndia #MetalFinishingSolutions #DeburringTechnology #SurfacePreparation #ManufacturingInnovation #MachinerySolutions #ValgroIndia #MetalFinishing #DeburringMachines #EdgeRounding #SurfacePreparation #ManufacturingExcellence #InnovationInManufacturing #IndustrialMachinery #ProductivityMatters #EngineeringSolutions