Something Revolutionary is Coming from Valgro India at IMTEX Forming 2026

Valgro India Limited, a leader in surface preparation and finishing solutions, is all set to create a new benchmark at IMTEX Forming 2026.

This year, we are not just participating — we are unveiling a game changer.

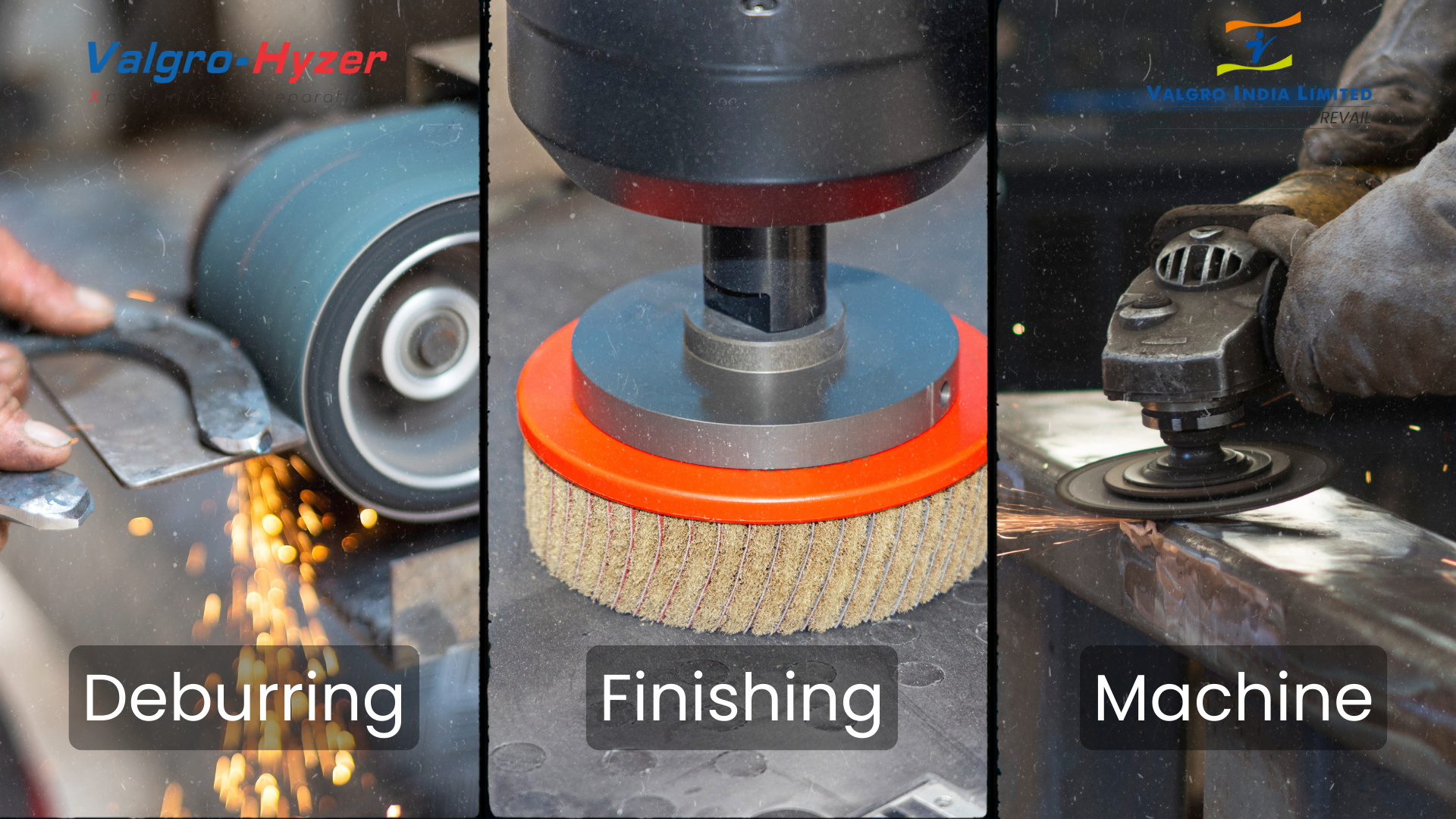

After years of research, engineering excellence, and customer feedback, Valgro is proud to announce the launch of a groundbreaking machine, designed for extreme productivity, precise deburring, and perfect edge rounding.

But here’s the catch:

We’re keeping the details under wraps… for now.

What we can reveal is:

- Unmatched speed without compromising finish quality

- Robust construction for industrial-grade performance

- Flexible processing for a wide variety of materials and thicknesses

- Future-ready automation features to boost your manufacturing efficiency

Why should you be excited? Because this machine will redefine the way you deburr, edge-round, and finish your metal parts, slashing your cycle times while delivering unmatched consistency and surface quality.

January 21–25, 2026

Bangalore International Exhibition Centre (BIEC), Bengaluru, India

Be among the first to witness the future of metal finishing —

Live. Loud. Only at Valgro India Booth.

“Stay curious. Stay ready. Something powerful is about to be revealed.”

Contact us to schedule a VIP demonstration:

+91 9825338847 – sales@valgroindia.com

#ValgroIndia #IMTEXForming2026 #DeburringInnovation #EdgeRoundingSolutions #NextGenFinishing #MetalForming #MachineryLaunch #SurfaceFinishing #ProductivityBoost #StayTuned #ValgroIndia #IMTEX2026 #DeburringRevolution #EdgeRounding #HighProductivity #NewLaunch #MetalFinishing #ManufacturingExcellence #InnovationInFinishing #SurfacePreparation #IndustrialExhibition #ValgroIndia #MetalFinishingSolutions #DeburringTechnology #SurfacePreparation #ManufacturingInnovation #MachinerySolutions #ValgroIndia #MetalFinishing #DeburringMachines #EdgeRounding #SurfacePreparation #ManufacturingExcellence #InnovationInManufacturing #IndustrialMachinery #ProductivityMatters #EngineeringSolutions