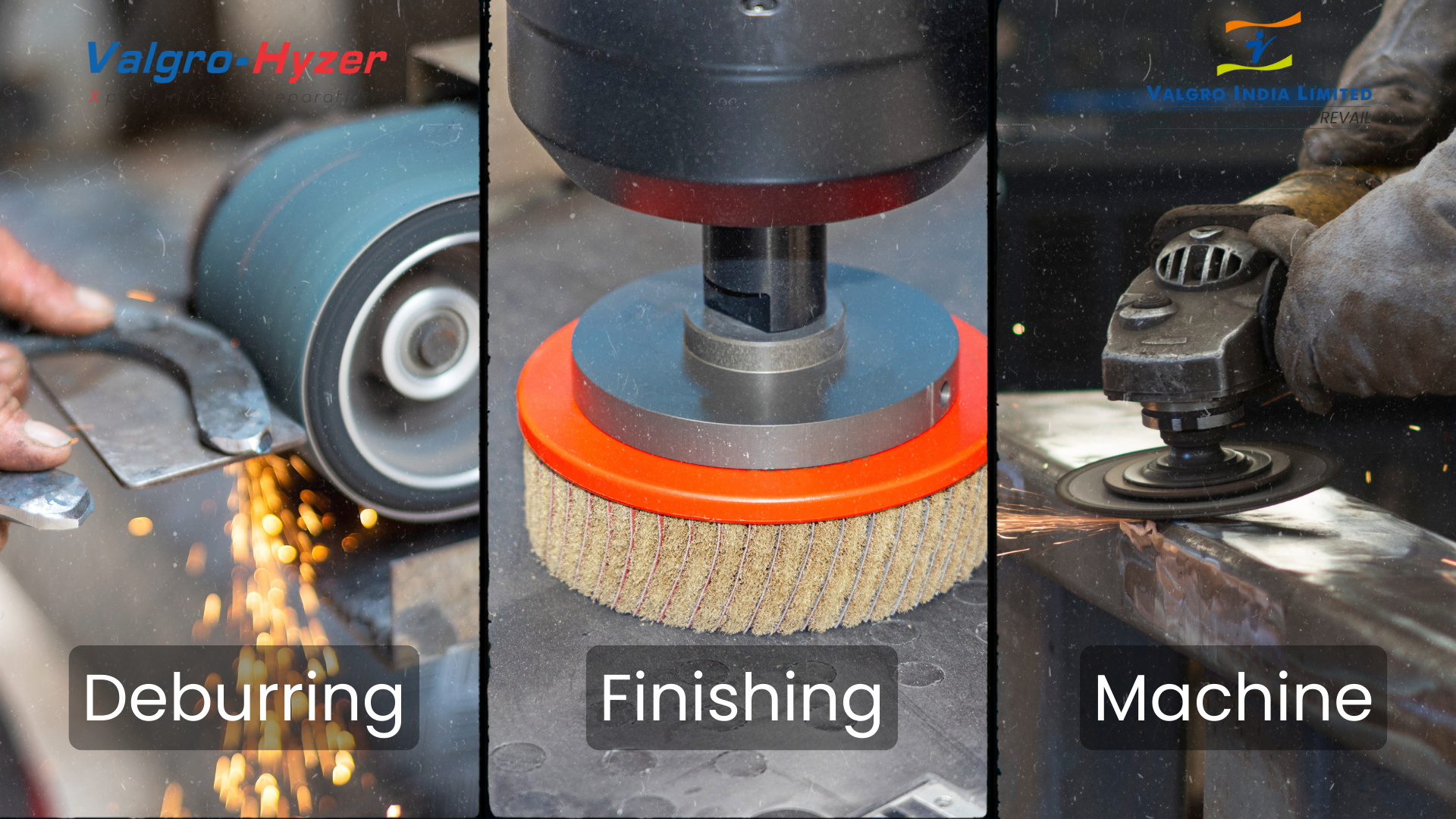

Discover the Future of Deburring & Edge Rounding with Valgro Lite Series

Valgro India at IMTOS Expo 2025

Dates: 11th to 14th July 2025, Hall – 2 Booth P13B, Venue: YashoBhoomi Convention Centre,

Location: Sector -25, Dwarka – New Delhi

Valgro India Limited, India’s leading manufacturer of surface preparation and metal finishing solutions, is excited to announce our participation in IMTOS Expo 2025, one of the most prestigious industrial trade shows in South Asia.

At this year’s event, we are proud to unveil our latest innovation—the Valgro Lite Series Deburring & Edge Rounding Machine. Designed to meet the evolving demands of modern fabrication shops, this compact-yet-powerful machine offers the perfect balance of performance, efficiency, and affordability.

What to Expect at Our Booth

- Live Demonstration of the Valgro Lite Series

Watch precision deburring and smooth edge rounding in action across laser-cut, punched, and sheared metal parts. - Compact Footprint, Big Capabilities

Engineered for small to mid-scale manufacturers, the Lite Series provides consistent and high-quality finishing with low power consumption and minimal floor space. - Talk to Our Experts

Meet our metal finishing consultants and engineers to discuss custom solutions, machine integration, and application-specific requirements.

About the Valgro Lite Series

The Lite Series is the ideal entry point into automated deburring for fabrication units that are ready to upgrade from manual operations. Key features include

- Single-pass burr removal and uniform edge rounding

- Suitable for mild steel, stainless steel, and non-ferrous materials

- Easy-to-use operator interface with adjustable speed control

- Compatible with various abrasive configurations for different finishes

- Designed for safety, efficiency, and cost-effectiveness

Why Visit Us?

If you’re looking to improve your part quality, reduce rework, and enhance production efficiency, the Valgro Lite Series is the machine you’ve been waiting for. Experience firsthand how our innovative solutions are transforming the future of sheet metal finishing in India and beyond.

Don’t Miss Out!

Visit Valgro India at IMTOS 2025 and take your finishing process to the next level.

#ENGIMACH2025 #ENGIMACHExpo #EngineeringExcellence #ValgroIndia #DeburringInnovation #SmartManufacturing #SurfaceFinishing #IndustrialAutomation #FutureOfManufacturing #IndustrialExhibition #ValgroIndia #MetalFinishingSolutions #DeburringTechnology #SurfacePreparation #ManufacturingInnovation #MachinerySolutions #ValgroIndia #MetalFinishing #DeburringMachines #EdgeRounding #SurfacePreparation #ManufacturingExcellence #InnovationInManufacturing #IndustrialMachinery #ProductivityMatters #EngineeringSolutions