Burr Classification – Definition & Valgro Solution

Class #1 Micro Burr :

Definition :

Micro burrs can only be observed using magnification. To the unaided eye, they appear as sharp edges. Grinding operations are a common source of this type of burr.

How To remove

Deburr by Nylox Abrasive brush, Valgro Nonwoven abrasive roller brush, Deburring tool.

Class #2 Feather burrs

Definition :

Feather burrs are readily visible without magnification and are characterized by extremely thin roots. They can be removed with a tip of a pencil.

How To remove

Deburr by Nylox Abrasive brush, Valgro Nonwoven abrasive roller brush, Deburring tool.

Class #3 Attach burr

Definition :

Burrs in this group are well-attached but relatively small. Despite their size, significant mechanical energy must be applied to remove them.

How To remove

The Valgro brush can sometimes remove class 3 burrs but offend a stock removal operation such as grinding / Scalping is requiring for complete removal.

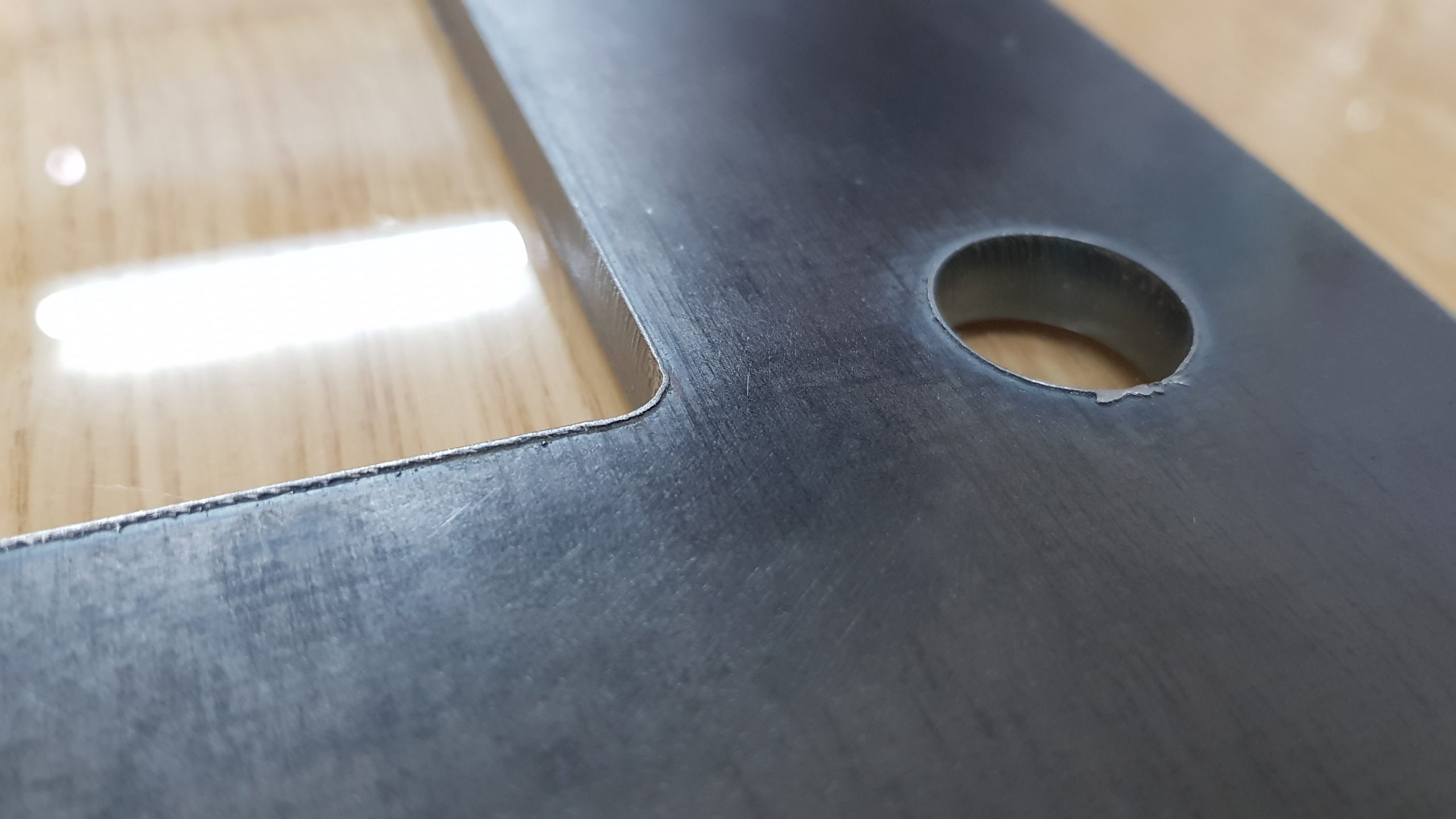

Class #4 Root burr :

Definition :

Like Class 3 burrs in this class are well- attached. The primary difference is size and root thickness.

How To remove

a stock removal operation such as grinding, Scalping, or machining is required for complete removal.

Class #5: Parent burr

Definition :

Class 5 burrs are exceptionally large with thick, rigid roots. Burrs in this class are different from conventional burrs because they are comprised of a displaced base material that is still fully- attached to the parent part.

How To remove

a stock removal operation such as grinding or machining is required for complete removal.

Please mail us for more detail suggestion