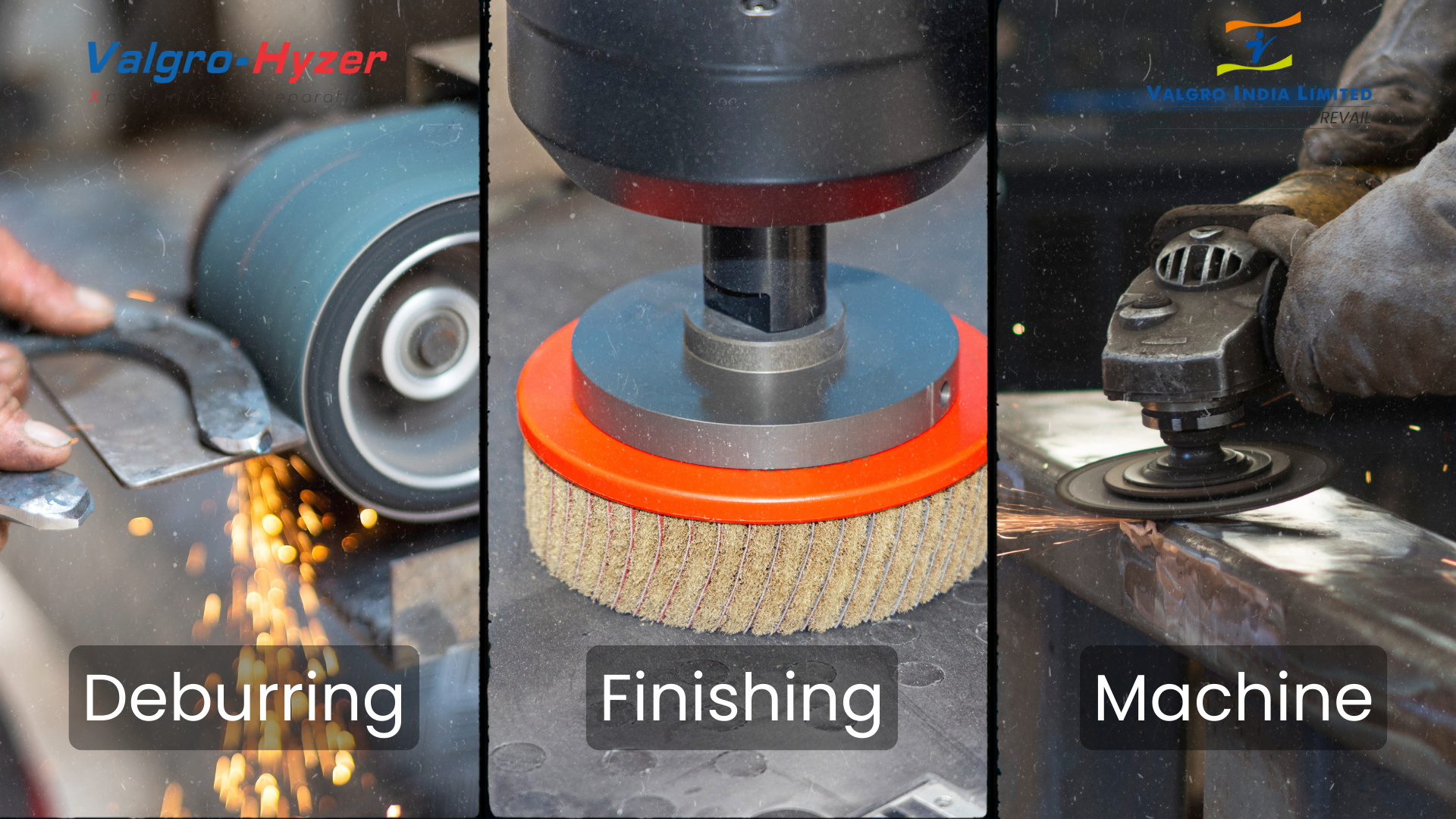

Planetary head Rotary brush burr removal and Roughening machine

Deburring + Roughening + Edge rounding

The Valgro Samarth Disc Expert Series Precision Deburring Machine is suitable for surfacing of nonferrous and ferrous sheet metals parts. Valgro brings to you the expertise in dealing with every surface , and offering cutting edge deburring technology with in-depth process knowledge. The range of Valgro Deburring Machines and Deburring Solutions extends from Machined Automotive Components to Punched and Fine Blanked Parts.

Suitable Burr Class #1 & #2 laser cut & Fine Blanking

Feature:

- Working thickness from 1mm to 100mm

- Single and multi-station Deburring station machine

- Dry process: Clean and Green environment

- Low Space requirement

- Save money and time

- Reduce labor and manpower cost

- Avoid less handling scratch due to in-house Deburring After cutting and before banding

Suitable for :

- Panel builder

- Sheet metal fabricator

- Automobiles

- Railways

- Instrumentation

- Laser cut shop