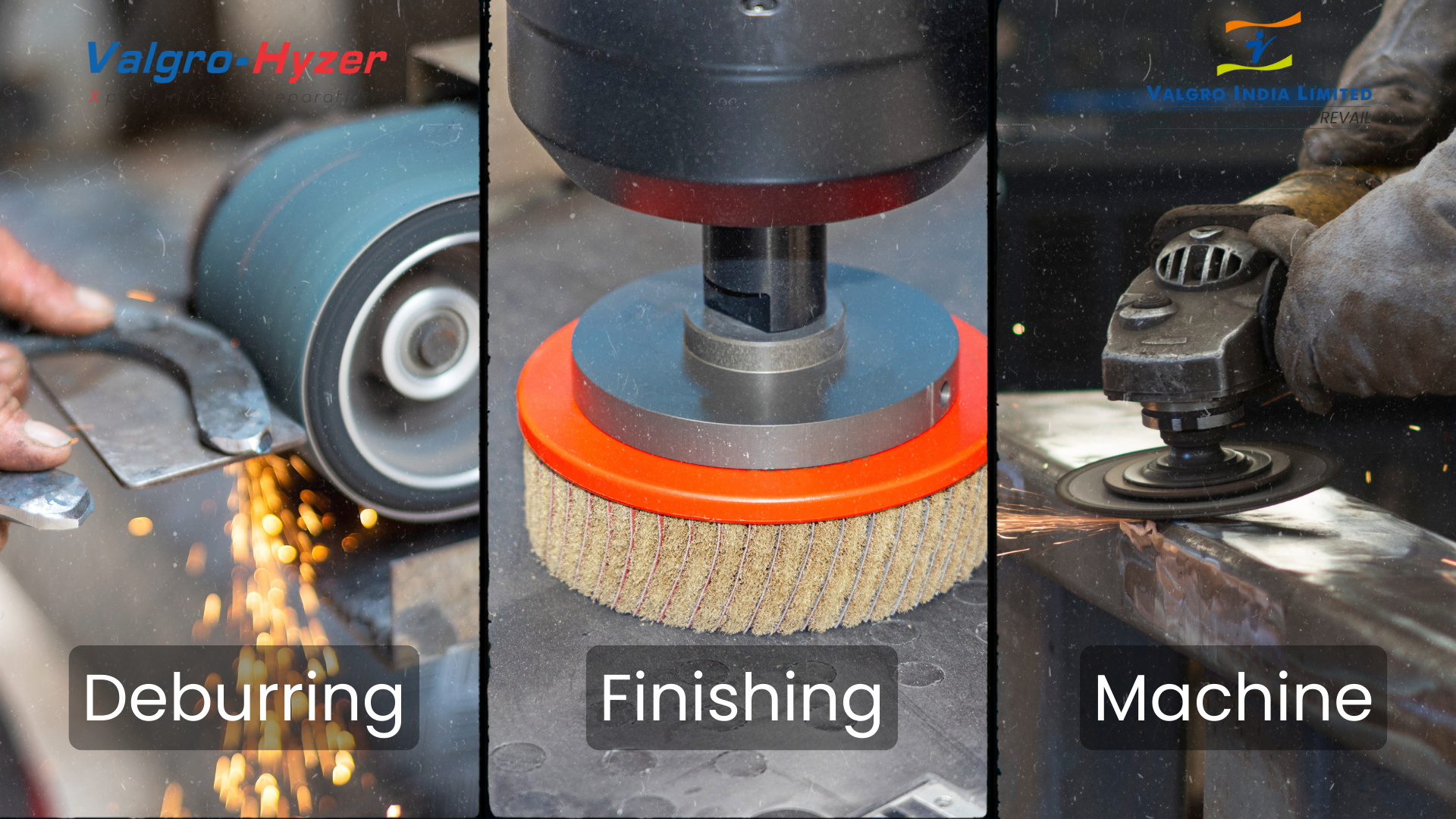

Processing stainless steel by Valgro Hybrid Series Polishing Machine

Stainless steel has become a widely used engineering material due to its excellent corrosion resistance, good mechanical properties, the processing performance of plane grinding and polishing machines, and good welding performance. At the same time, through different polishing methods, the surface of various stainless-steel plates, pipes, rods, and profiled materials can have different levels of surface finish, which greatly improves the appearance of stainless steel and achieves an aesthetic effect.

For different metal materials, different use occasions, and different requirements for the surface of metal workpieces, different grinding methods or a combination of several grinding methods must be used for grinding processing to make the processed workpiece meet the requirements for use.

The “chemical polishing” of the plane grinding and polishing machine is a process of preferentially dissolving the convex parts and the concave parts of the surface to be polished to improve the roughness of the metal surface and obtain a smooth and bright surface.

“Mechanical grinding” is the process of removing the convex part of the surface to be cut, worn or plastically deformed to obtain a smooth and bright surface.

For More detail, please write a mail at sales@valgroabrasives.com

Dr. Arvind Patel