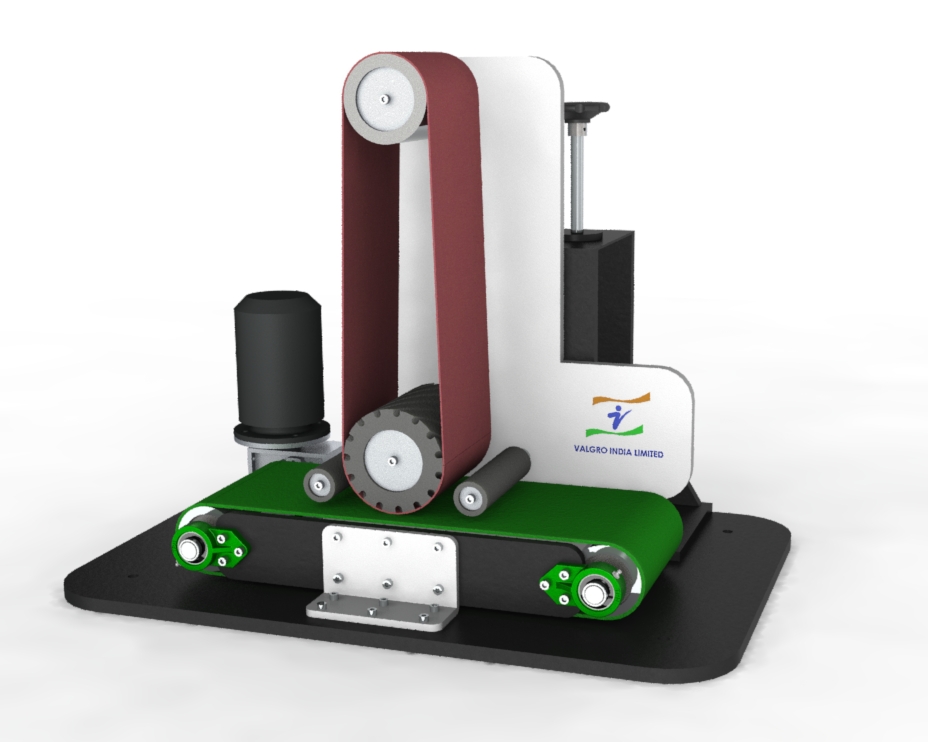

Elevate your deburring operations with the Valgro VBS Series Compact Burr Removal Machine—designed specifically for small-scale sheet metal industries seeking advanced, efficient, and precise deburring solutions.

It combines efficiency, high-quality performance, and affordability, making it a standout choice for those looking to enhance their deburring processes without exceeding their budget.

Features

- Effectively removes burrs from sheet metal components, ensuring smooth edges and improved product quality.

- It includes intuitive controls that simplify operation and facilitate quick integration into existing workflows.

- It comes with low power consumption, underscoring cost savings and environmental benefits.

- It can handle a variety of materials and thicknesses, catering to diverse manufacturing needs.

- Its robust construction and reliable performance ensure long-term operation with minimal maintenance.

Benefits:

- Enhanced Efficiency: Streamline your deburring operations with a machine that offers consistent, high-quality results, reducing manual labor and improving productivity.

- Precision and Accuracy: Achieve unmatched precision in your deburring tasks, ensuring superior finish quality for metal components.

- Cost-Effective Solution: Gain access to advanced deburring technology at an affordable price, making it an excellent investment for small-scale industries and DIY enthusiasts.

Upgrade to the Valgro VBS Series Compact Burr Removal Machine and experience a new standard of efficiency and precision in your deburring operations. Discover how this advanced tool can transform your workflow and meet the demands of today’s dynamic market.

- Sheet Metal Industries: Perfect for small-scale operations that require reliable and efficient deburring solutions.

- DIY Enthusiasts: Ideal for hobbyists seeking a compact, high-performance tool to achieve professional-quality results.

- Small Workshops: Provides a versatile and space-saving option for workshops needing a reliable deburring machine without a large footprint.