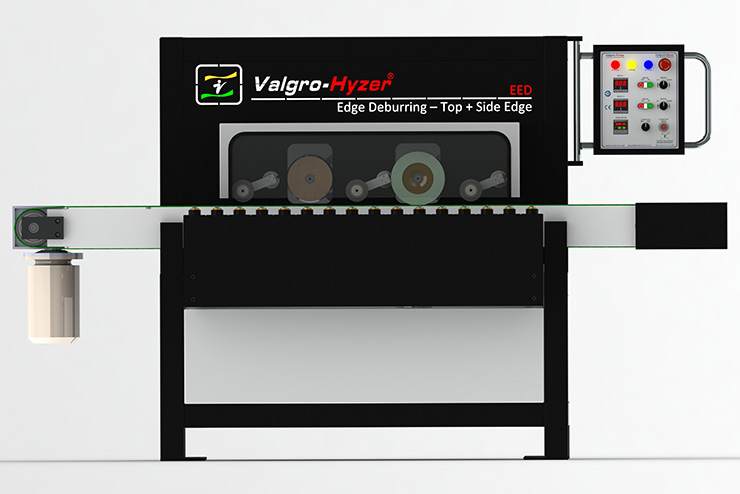

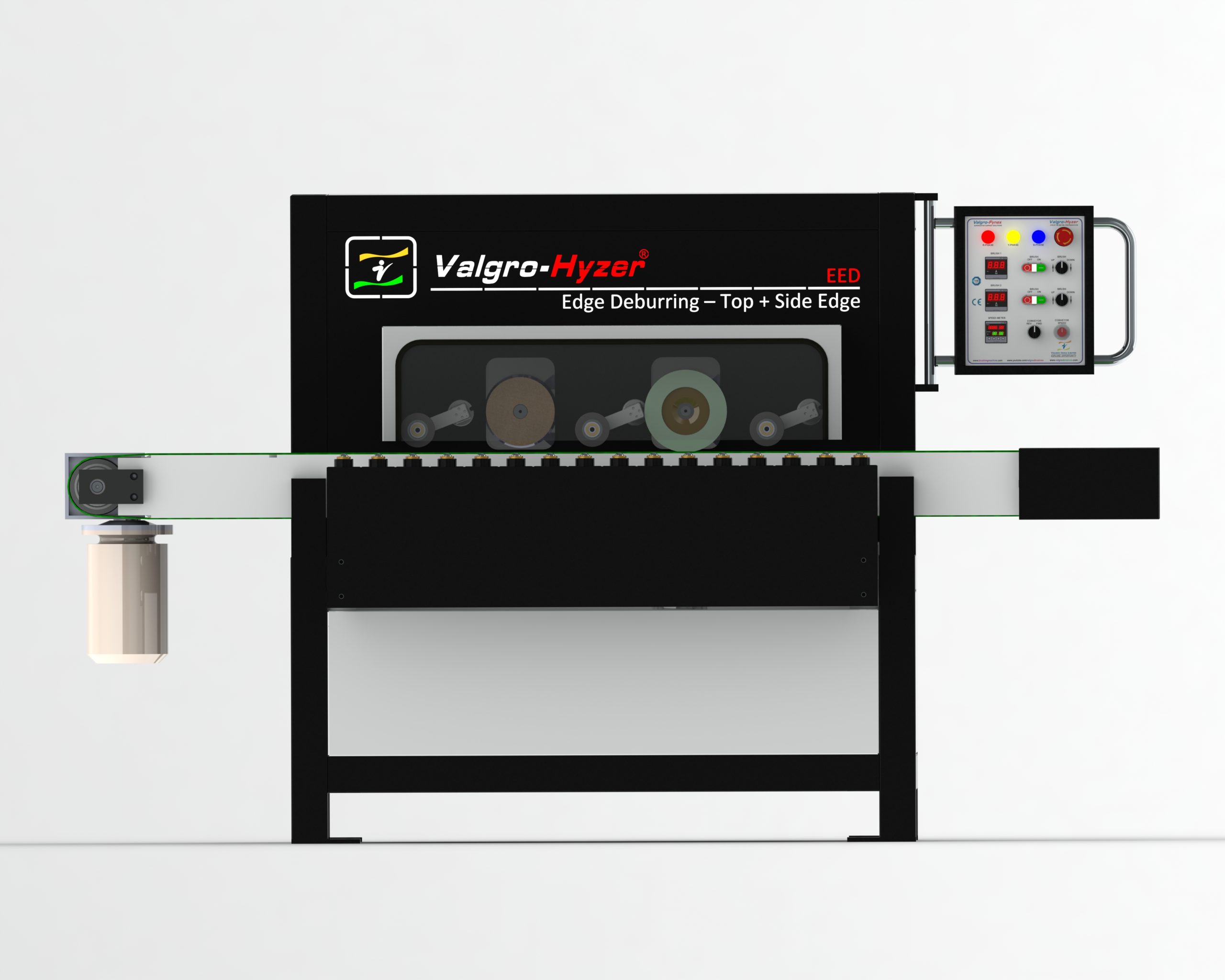

Valgro India Limited’s Micro Strip End Edge Deburring and Finishing Machine accommodates various strip diameters, with thickness ranging from 0.8mm to 2mm and breadth from 3mm to 12mm. Recently, a 6mm micro strip polishing equipment with side edge deburring was manufactured and exported to a valued customer at a Thai MNC. We extend our gratitude to our esteemed clients for their trust in our products and for providing us with the privilege to serve them

Features:

- Two Deburring wheel station is working on from side

- Top and side edge deburring by abrasive deburring wheel

- Tilt the sheet for another side burring.

- Sheet Auto Feed Conveyor Transport system

- Easy abrasives tools replacement

- Emergency security switch

- Reversal conveyor speed for emergency control

Advantage compared to the traditional deburring process:

- Avoid unhealthy position compared to the traditional operation

- No Physical Strain of worker by vibrations and flying spark

- Employee do not suffer under flying spark, dust and noise

- Unskilled labor run this machine

- Save money and time by less down time

Technical Specification

Applications

- Sheet Metal Processing

- Side Edge wall grinding

- Top Shear edge deburring

- Micro Joint Removal