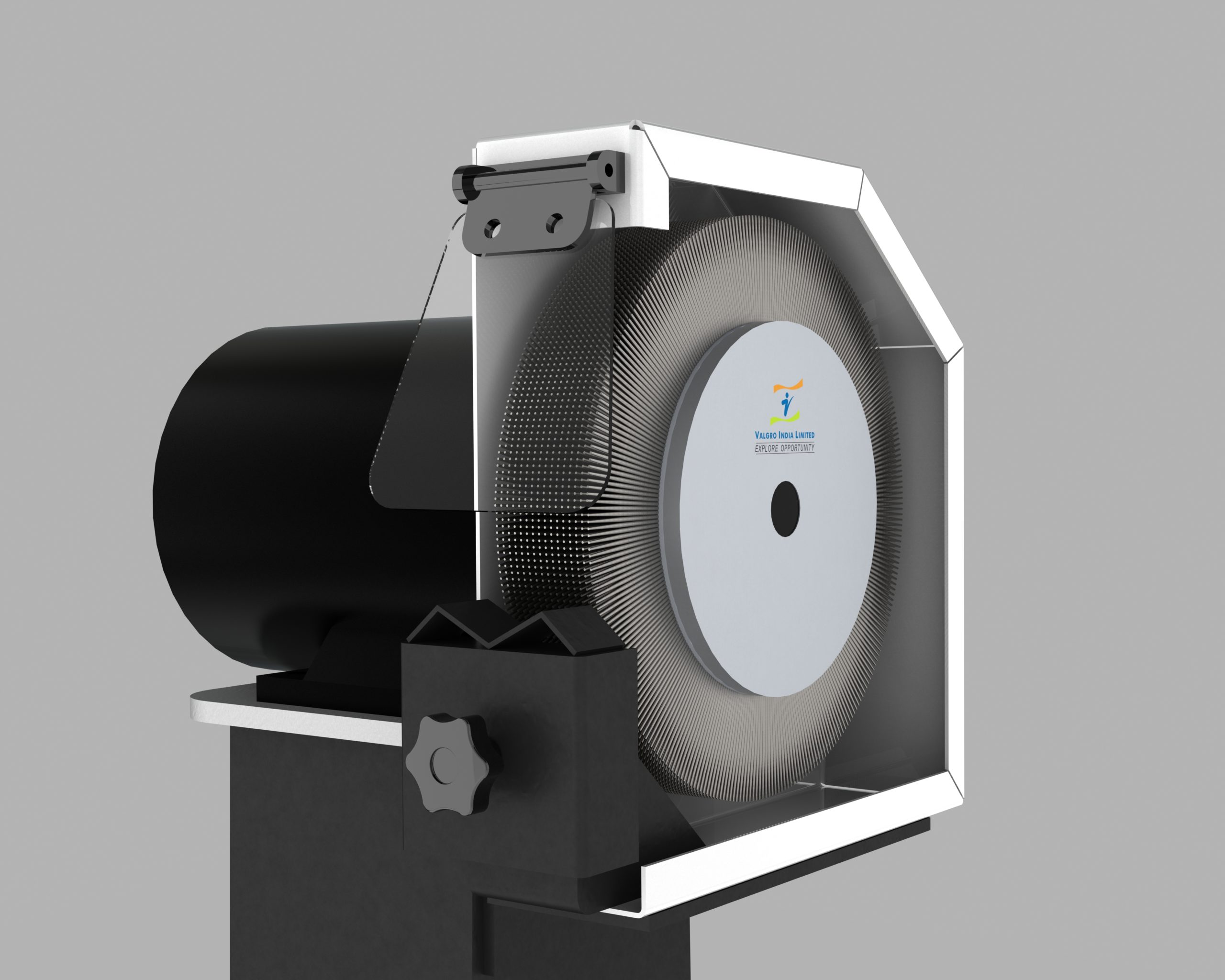

This economic version of deburring machine can also be used in various operations from small workshops to huge factories. Easy and fast deburring off all kinds of profiles (inner borders included) and full materials by steel turning the brush. Suitable for offhand application. In-build burr collection system with all safety features

Features:

- The deburring machine is built on solid columns

- Powerful 3.0 HP motor which can deal with the largest deburring projects.

- Ideal for small workshops and industry alike.

- Valgro metal fabricating machines are manufactured in the EU with only the best materials and components.

Benifits:

- Avoid unhealthy position compared to the traditional operation

- No Physical Strain of worker by vibrations and flying spark,

- Employees do not suffer under flying spark, dust, and noise.

- Unskilled labor run this machine

- Save money and time by less downtime

Technical Specification

Burr-free tubes play a crucial role in the automobile and sheet metal industries, particularly in achieving superior joint quality and precise welding. The removal of burrs from tubes is essential to ensure a perfect fit and prevent leakage during liquid transportation. This draught aims to highlight the significance of burr-free tubes in these industries and their benefits for achieving high-quality joints and precise welding.

Deburring edges is essential in modern sheet metal processing in order to produce reliable and high-quality parts. Deburring machines reliably remove any burrs left on the parts and help to ensure that the downstream processes function smoothly.