Valgro RBM Series is a universal, single-sided dry deburring machine engineered for complete post-processing of punched and laser-cut parts—all in one compact, production-ready line.

It delivers:

- Reliable deburring

- Consistent edge rounding

- Uniform surface finishing

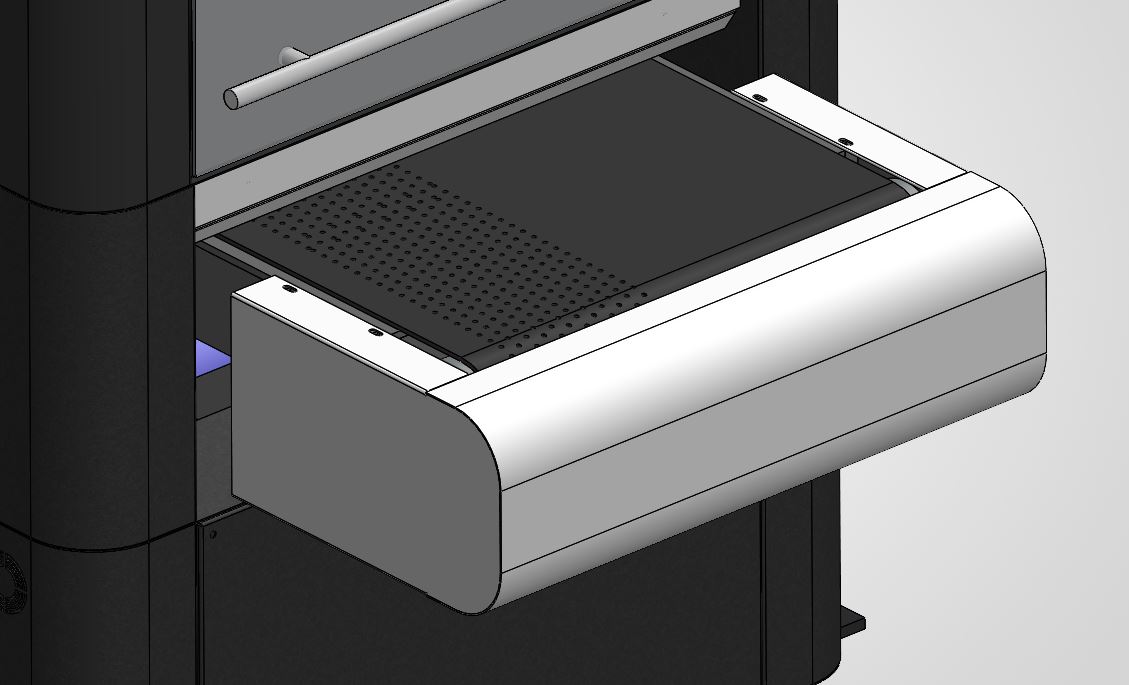

Designed for both small and large parts, RBM achieves a highly even edge rounding result and can produce up to R2 mm radius where required. With a vacuum conveyor belt, even lightweight and small components remain stable during processing—ensuring repeatable output and minimal rework.

All-in-One Processing Versatility

Unmatched Edge Rounding Up to R2 mm

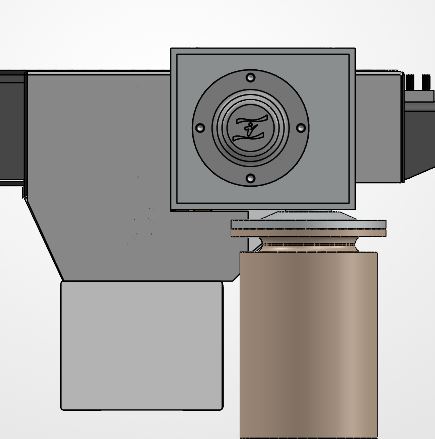

User-Friendly Touchscreen HMI

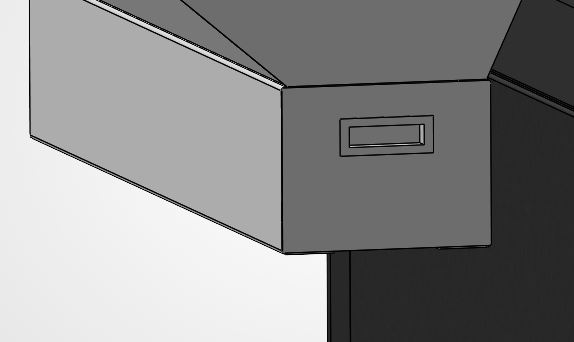

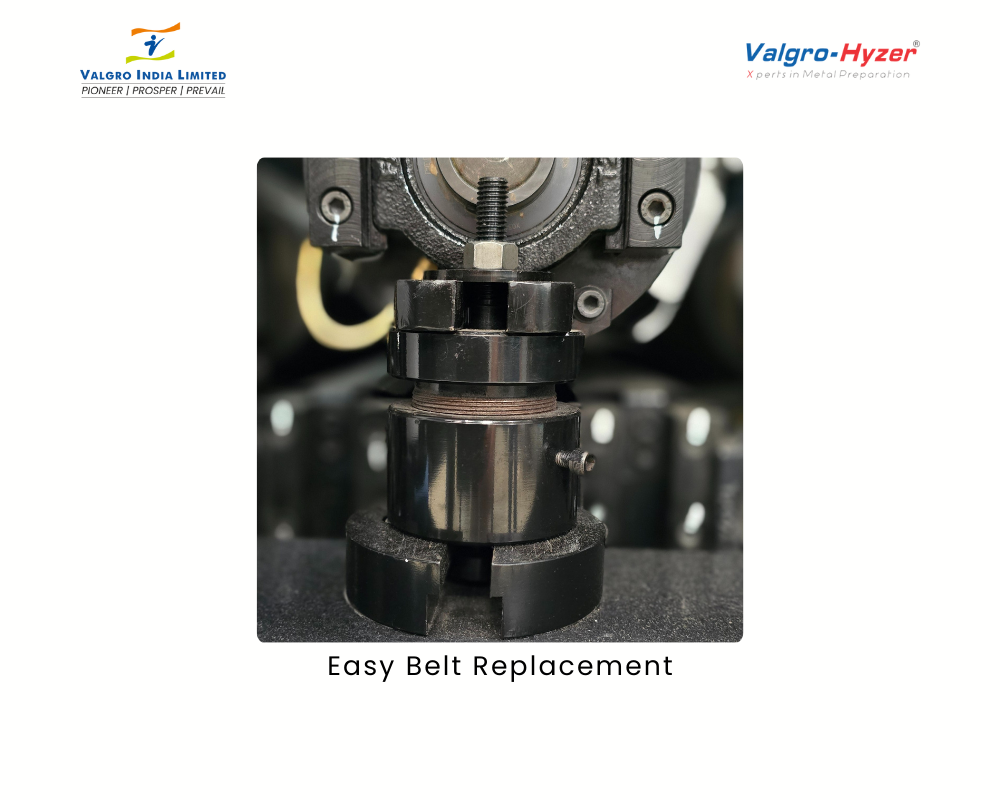

Quick Change Abrasive Media

Automatic Calibration & Media Wear Compensation

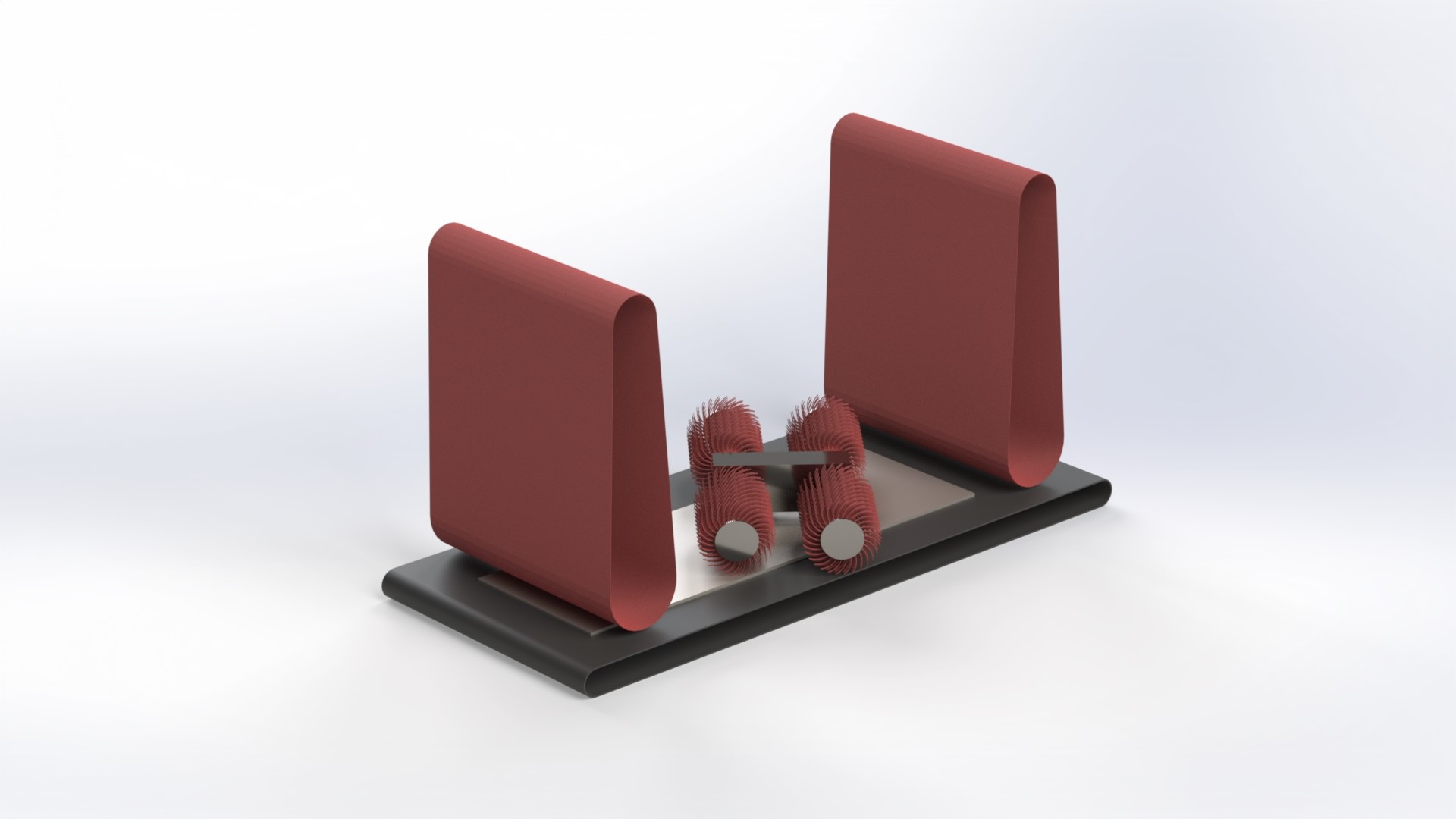

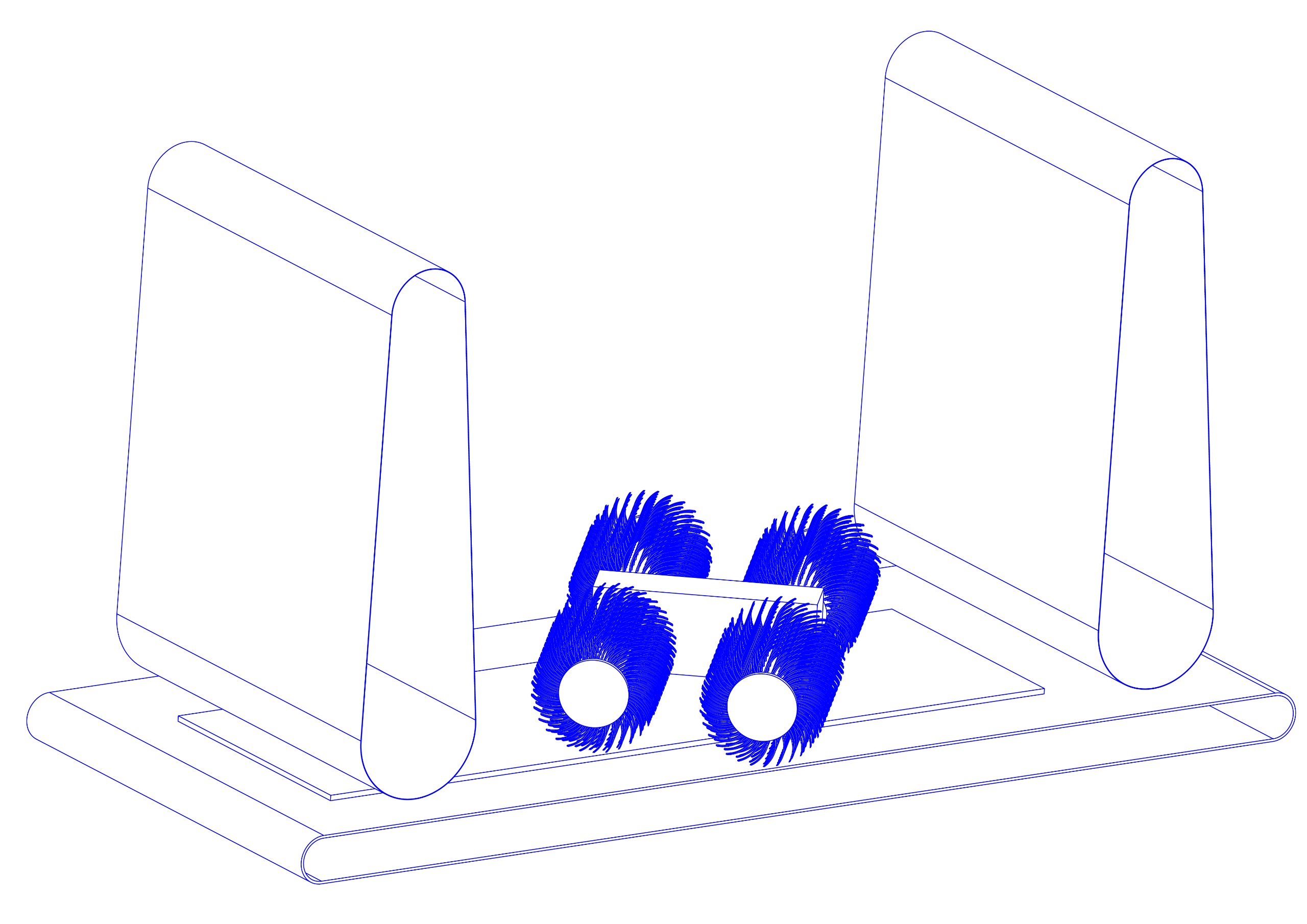

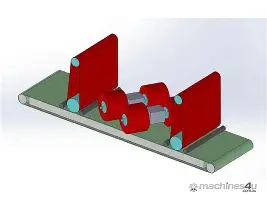

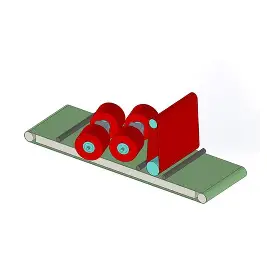

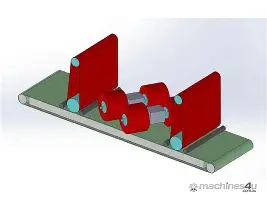

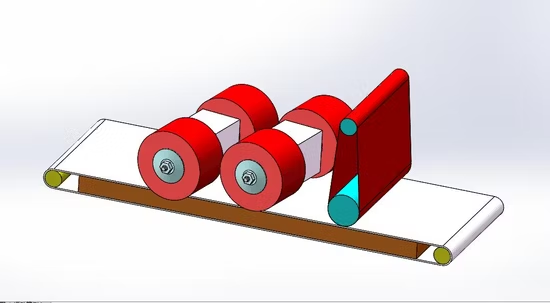

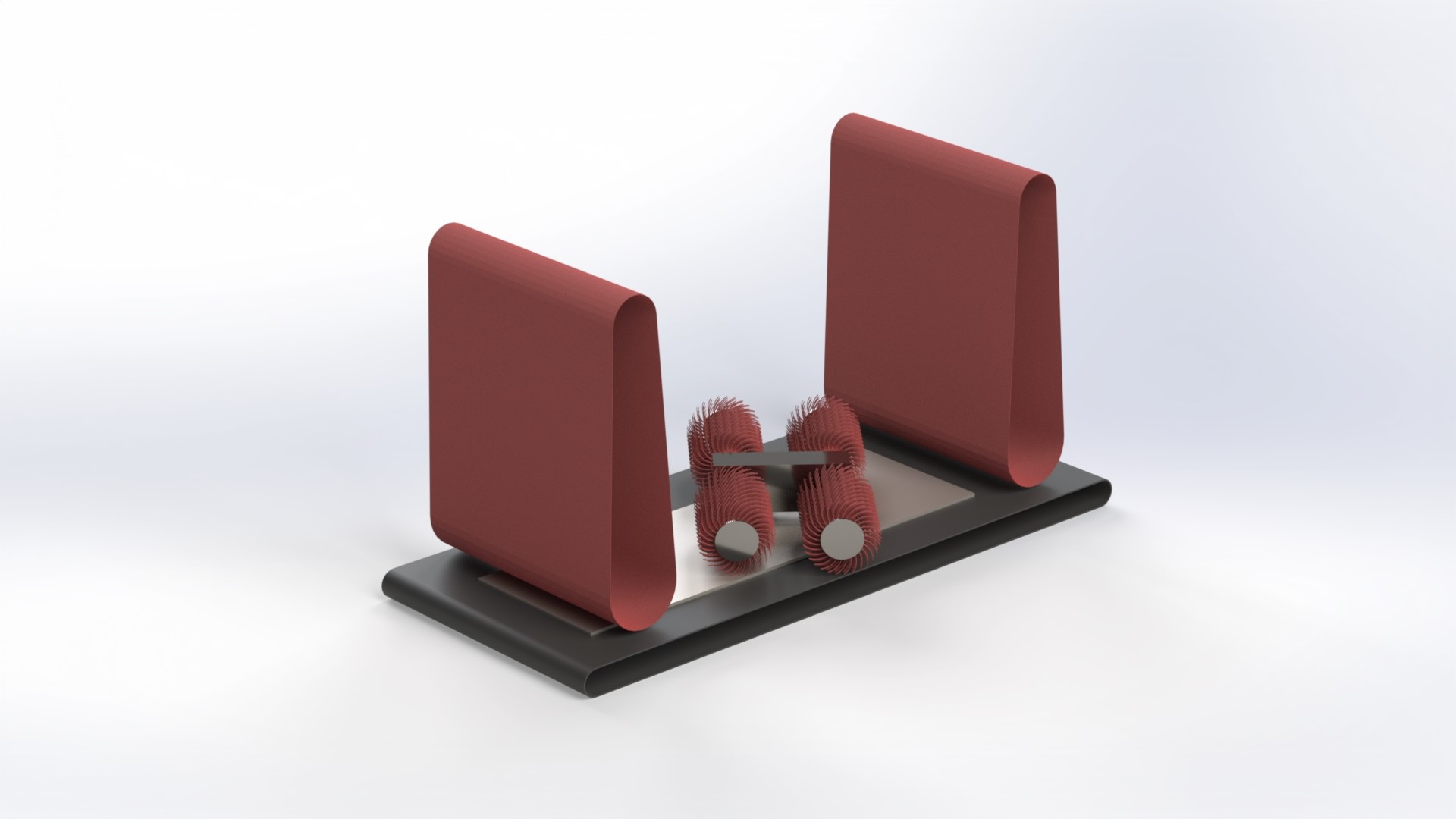

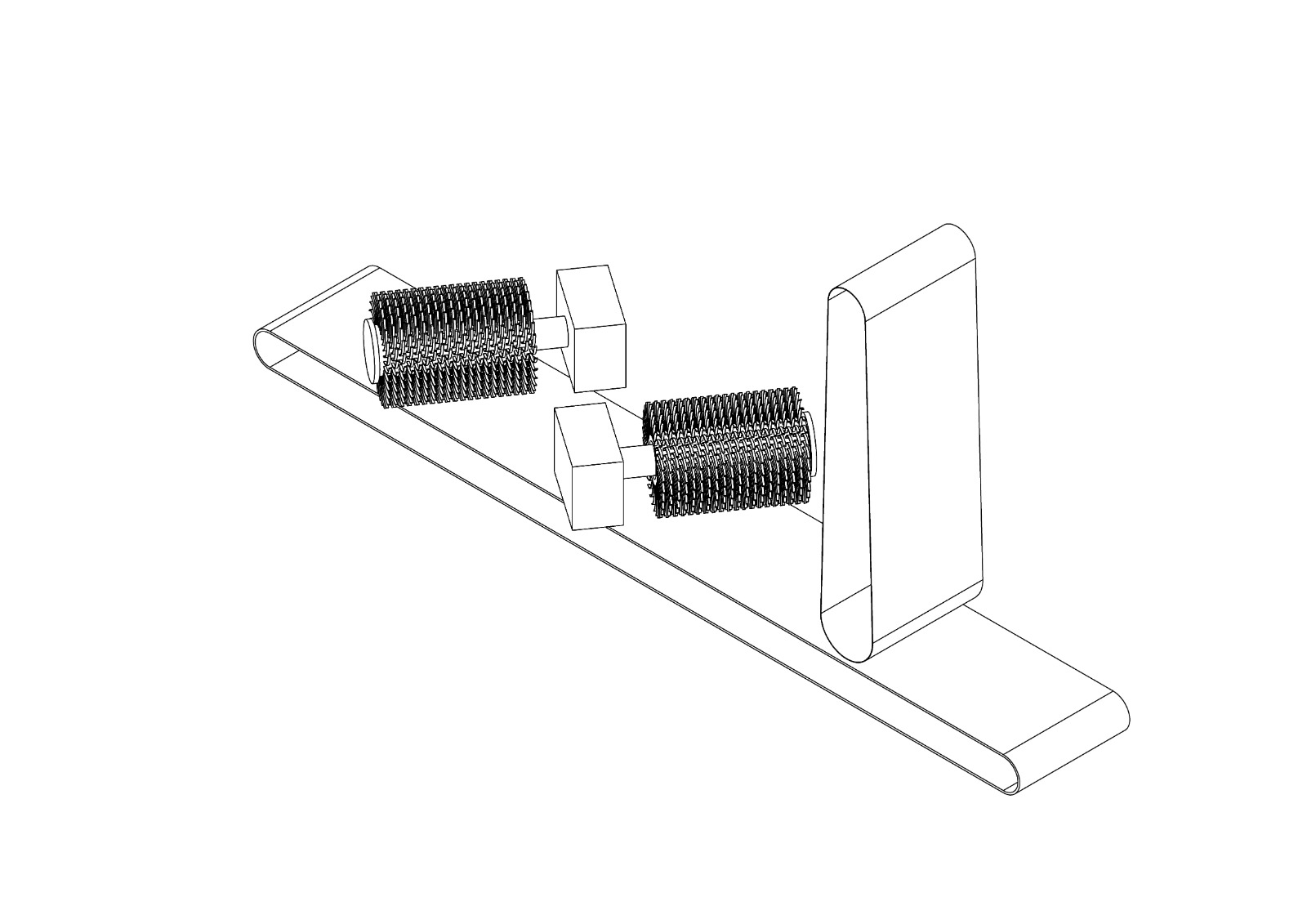

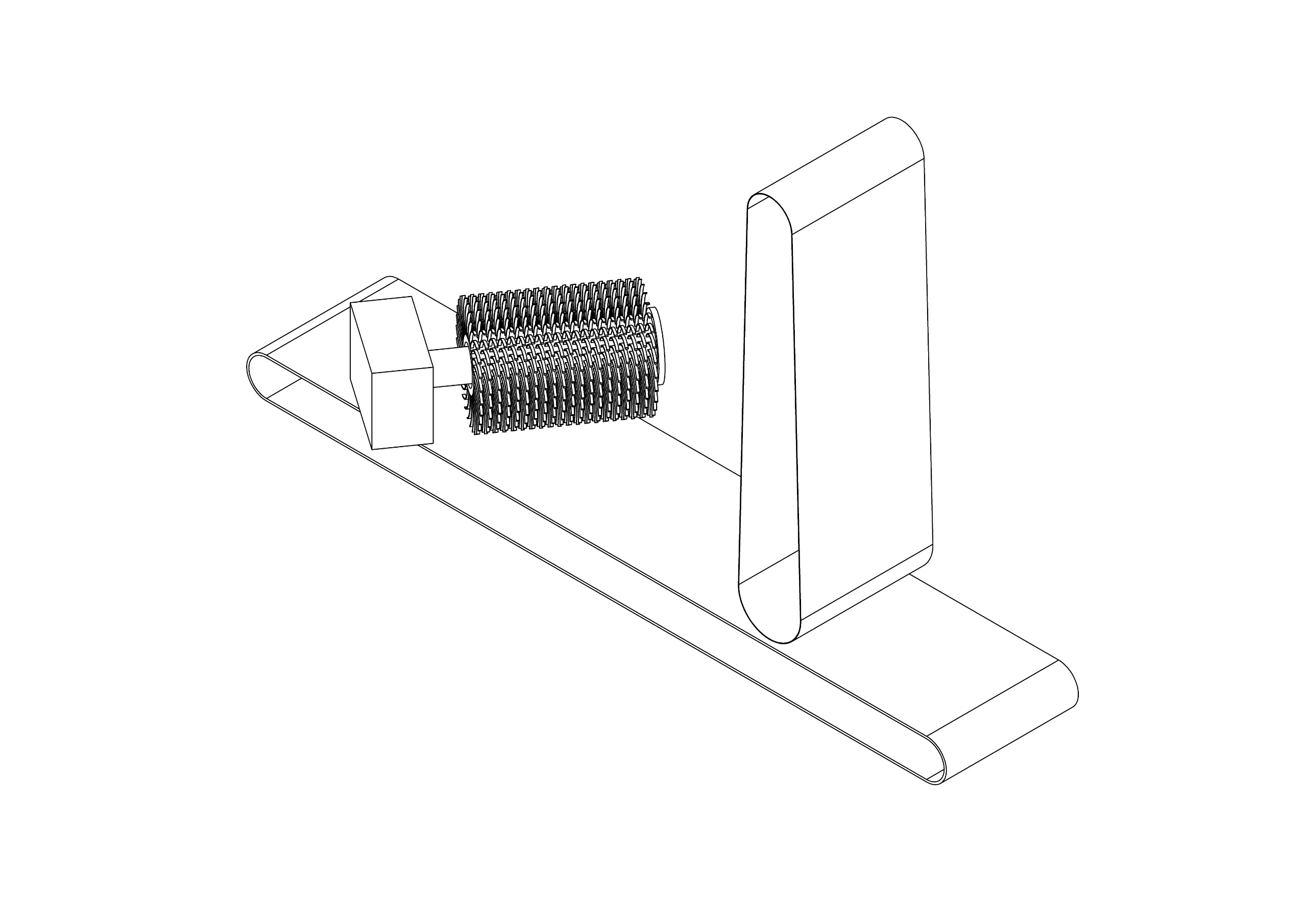

Valgro RBM integrates multiple stations in a single line to deliver a complete finishing cycle:

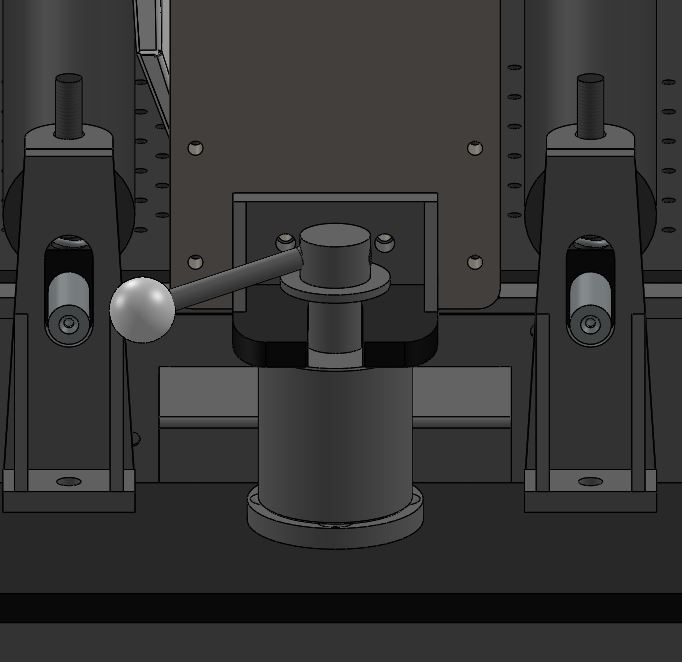

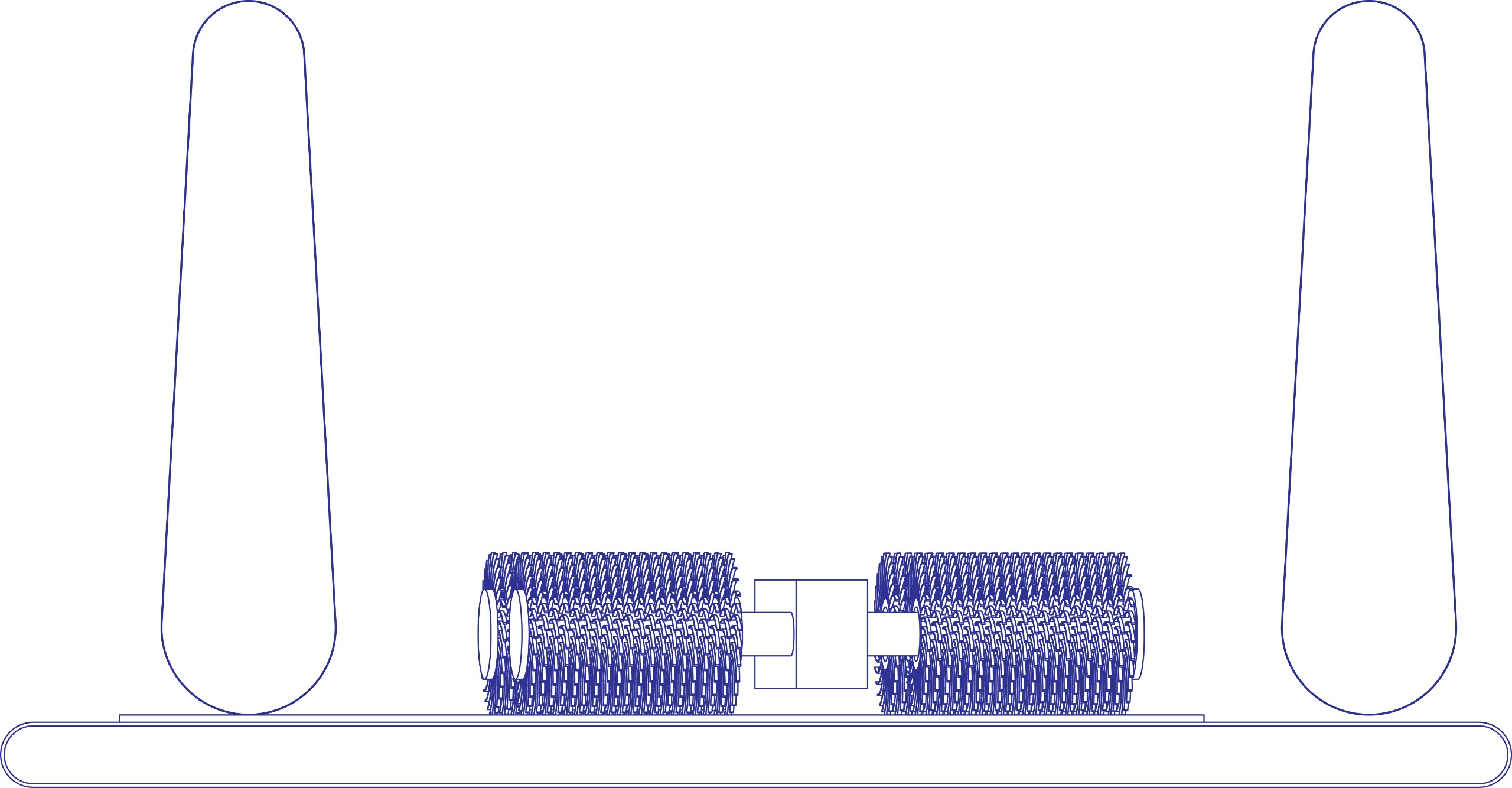

- Grinding Belt Unit: removes laser/punch burrs, slag traces, and sharpness (primary deburring)

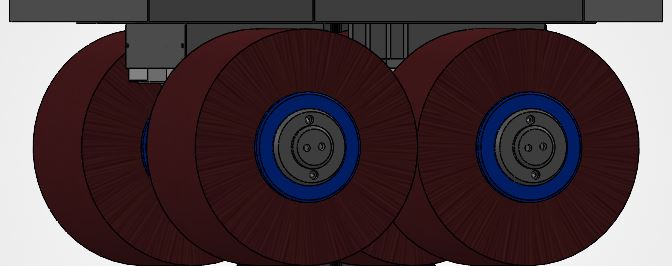

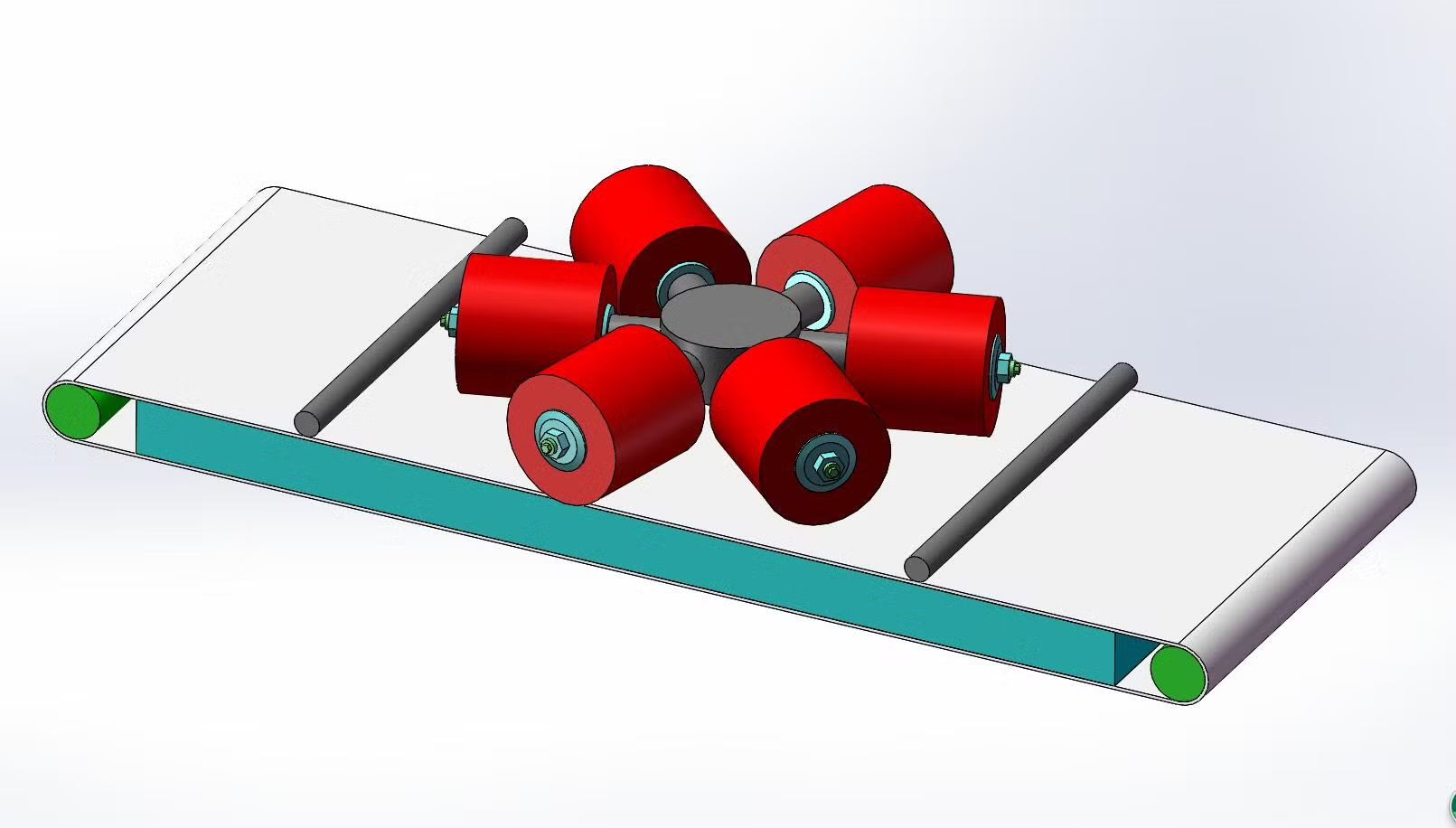

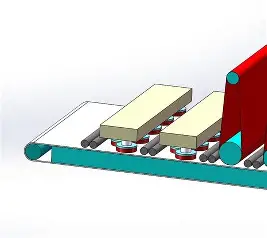

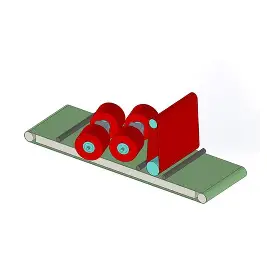

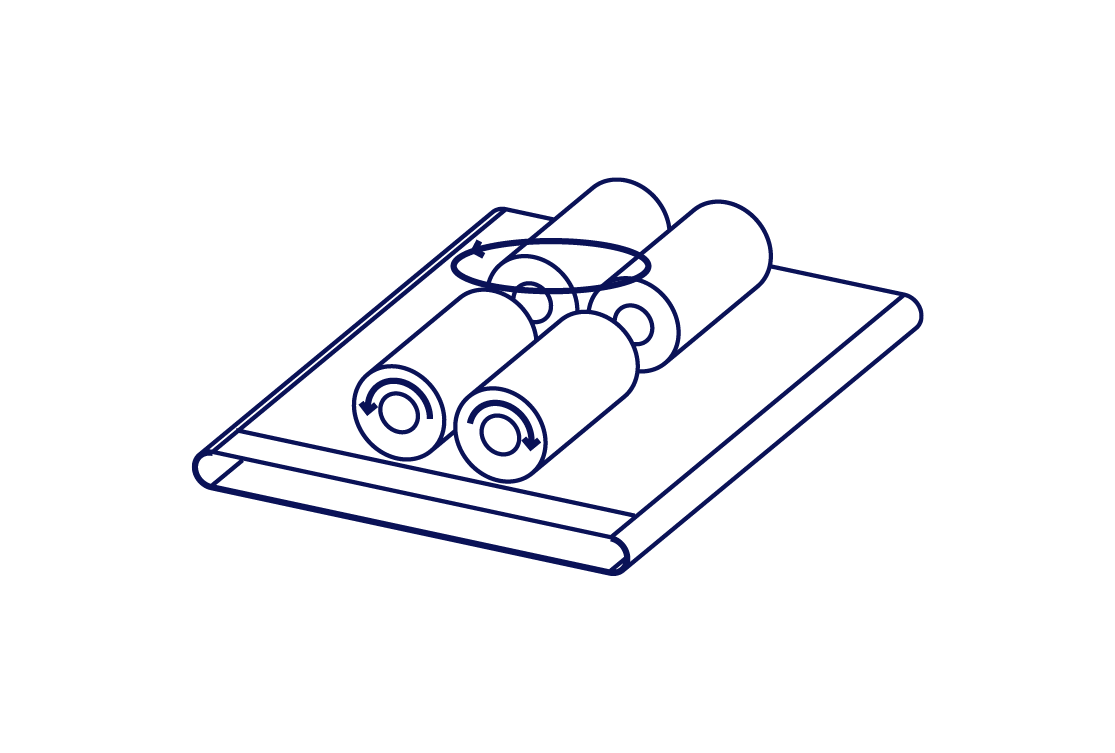

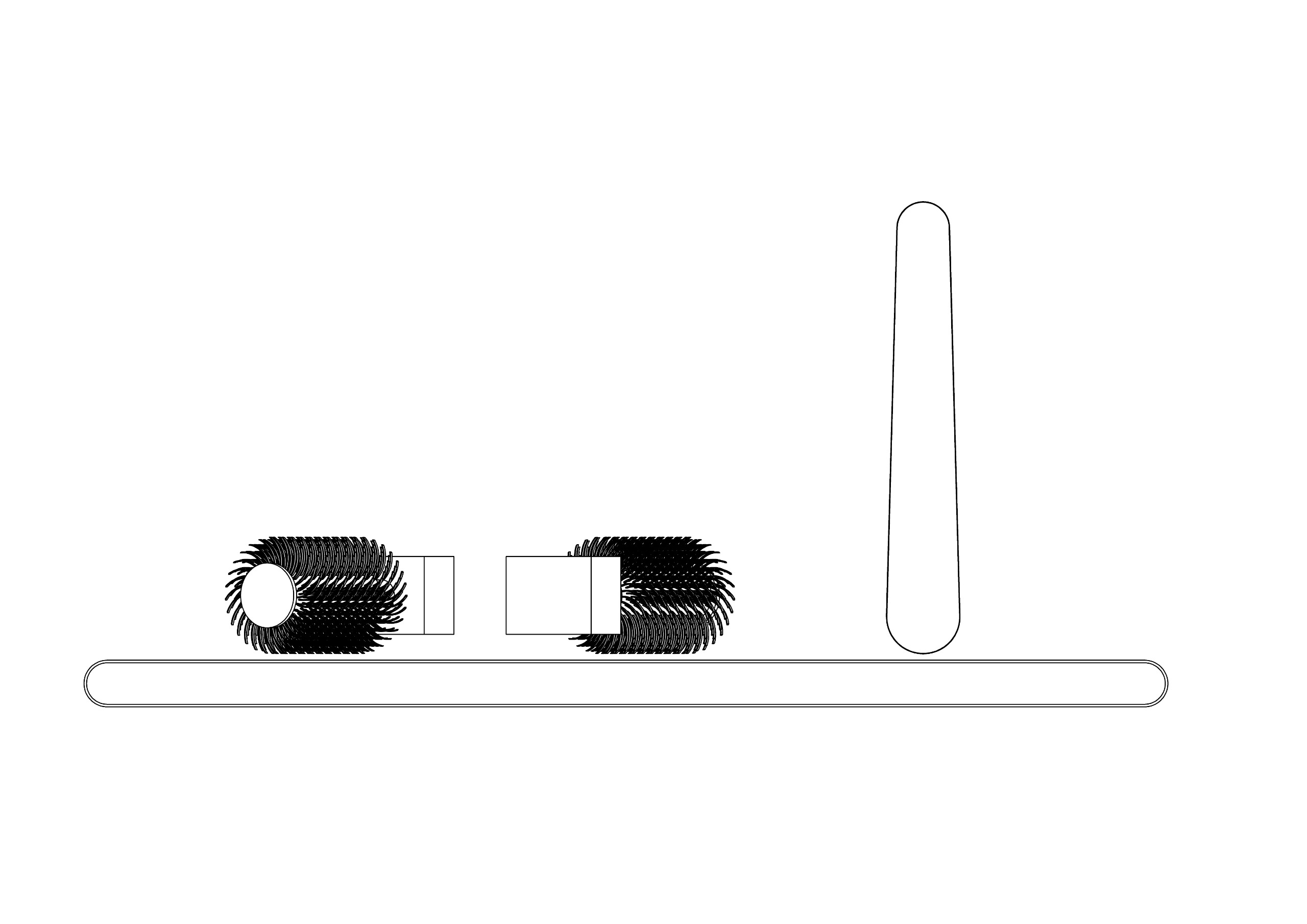

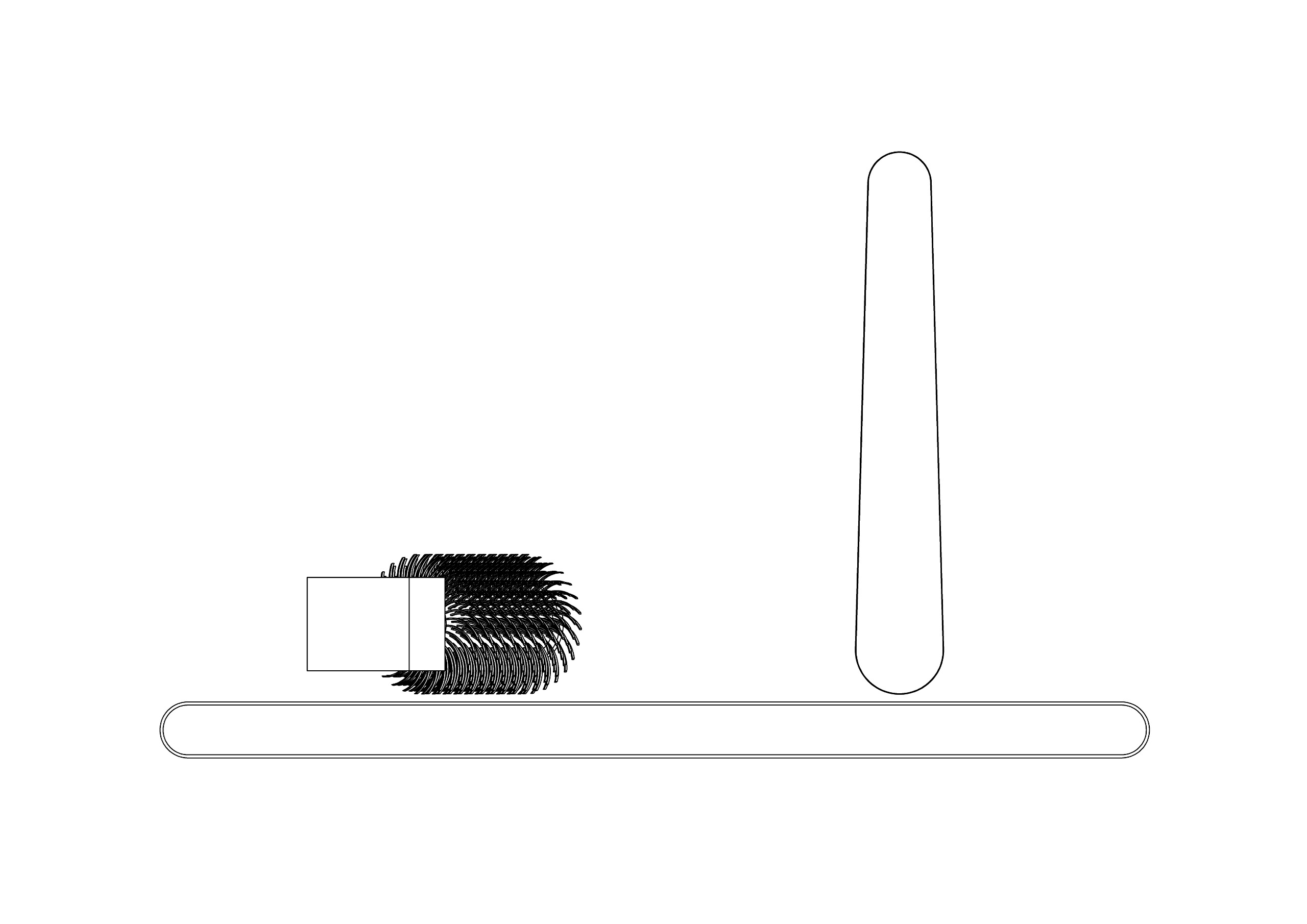

- Rotary Brush System: creates controlled edge rounding on profiles and contours

- Finishing Roller Unit: provides a uniform surface finish (satin / matte type finish depending on abrasive selection)

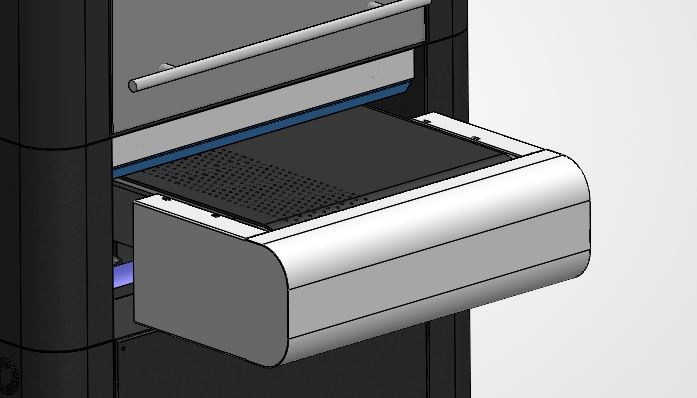

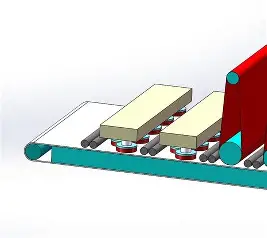

- Vacuum Conveyor Belt: securely holds small parts and thin sheets for stable processing

Result: stable edge quality, repeatable radius, and consistent surface appearance—ready for downstream processes like powder coating, painting, plating, and welding.

- Processing: Single-sided, dry

- Material thickness: 0.5 – 25 mm

- Max. working width: 1300 mm

- Machine weight: Approx. 6,500 kg

- Machine dimensions (L × W × H): 2100 × 4200 × 2350 mm

Application

RBM Series is ideal for industries and parts where edge safety, fitment, and finishing consistency matter:

Suitable for:

- Laser-cut sheet metal parts

- Punch press components

- MS / SS / Aluminum parts (dry processing)

- Flat parts requiring burr-free edges before coating or assembly

Typical use cases:

- Electrical panels, enclosures, brackets

- Automotive & EV sheet metal components

- General fabrication parts needing safe edges

- Parts requiring improved coating adhesion and uniform finish

- Metal Fabrication: Ideal for finishing and deburring metal parts in fabrication shops.

- Automotive Industry: Suitable for processing automotive components requiring precise finishing.

- Electronics: Perfect for deburring and finishing electronic enclosures and panels.

- Aerospace: Used for high-precision finishing of aerospace components.

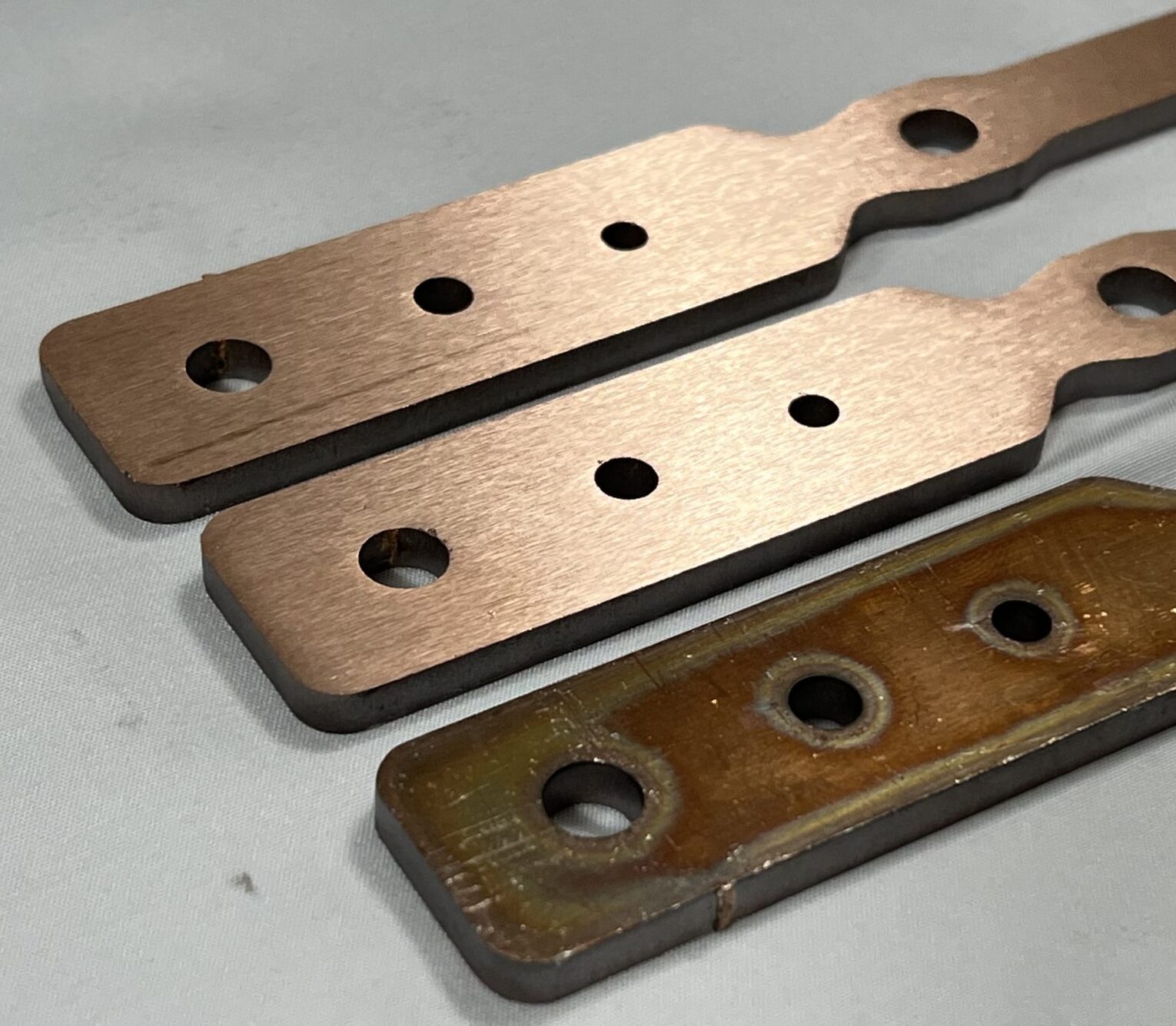

- Bus bar: Deburring punched, nibbled, sheared, or laser-cut sheet metal parts.

- Coating: Deburr and sand a radius to the sharp edge on cut out parts

- Plasma: Uniform sanding on all edges, leaving a fine scratch pattern on the surface.

- Marble: Deburring of all edges in one pass on laser cut or stamped parts

- Railway: Calibrating or keying carbon, rubber, wood, or other soft materials.

- Laser: Grain finishing and stock removal of any material.