Valgro India’s sheet edge preparation machines are expertly designed and highly user-friendly, providing efficient solutions for cut-edge preparation after shearing. Our advanced deburring machines are specifically engineered to remove metal burrs from the external perimeter of sheet metal, ensuring a smooth and safe finish.

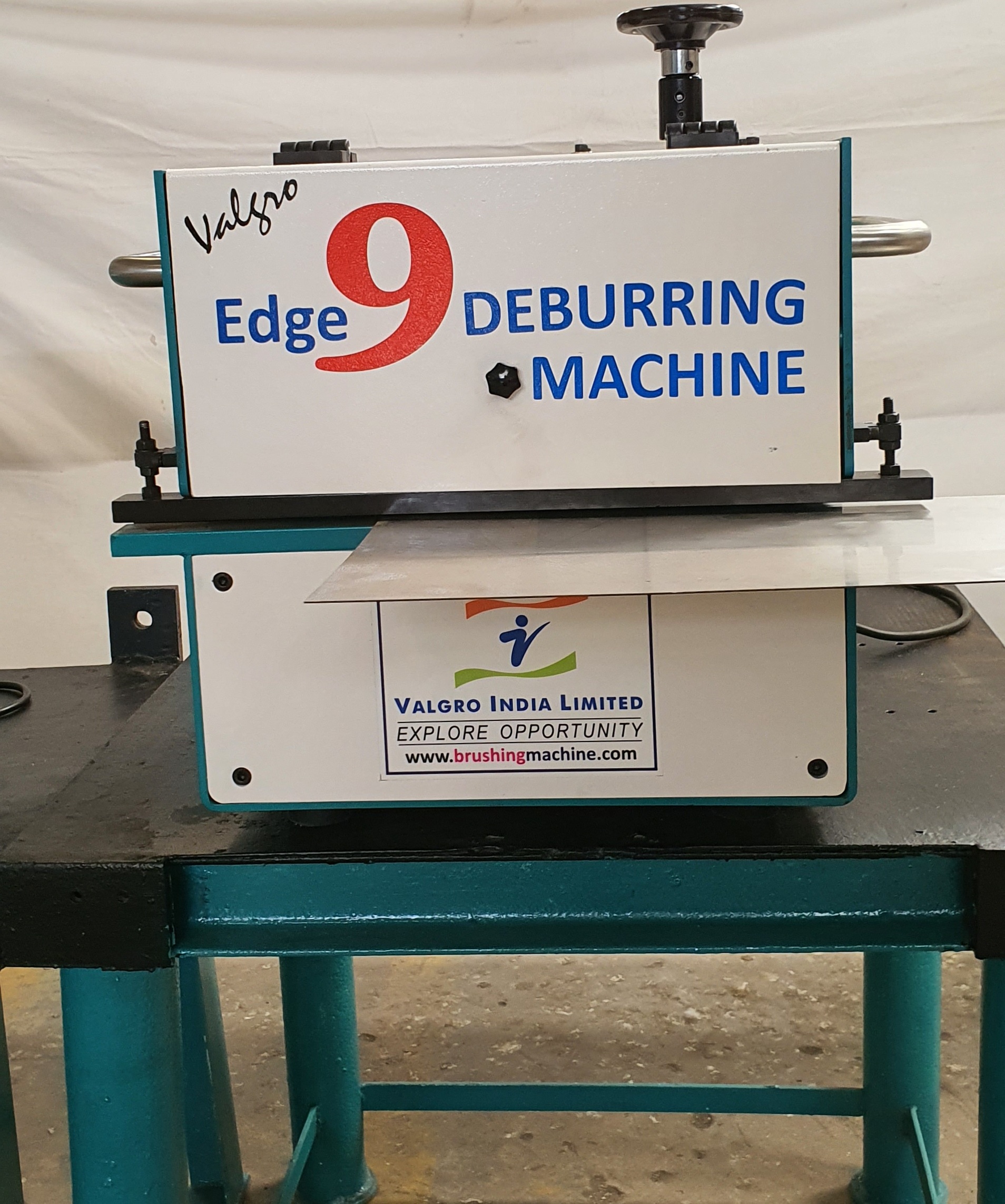

- User-Friendly Design: Edge 9 is user-friendly and requires minimal training, making it accessible to operators of all skill levels.

- High Efficiency: Quickly and effectively removes burrs from shearing, punching, and other cutting processes.

- Versatile Application: Suitable for various types of sheet metal and edge conditions. Sheet Edge Preparation Machine is compatible with various types of metals like Stainless steel, Mild steel, Copper, Brass, aluminum etc.

- Safer workspace: Designed to minimize operator’s exposure to sparks, dust, and noise.

- Time efficient: Save money and time with our latest technology, compared to traditional method.

Why deburring is essential?

- Safety: Eliminates sharp edges that pose safety hazards.

- Aesthetics: Enhances the visual appeal of the finished product.

- Quality: Ensures a smooth, burr-free edge, crucial for further processing or assembly.

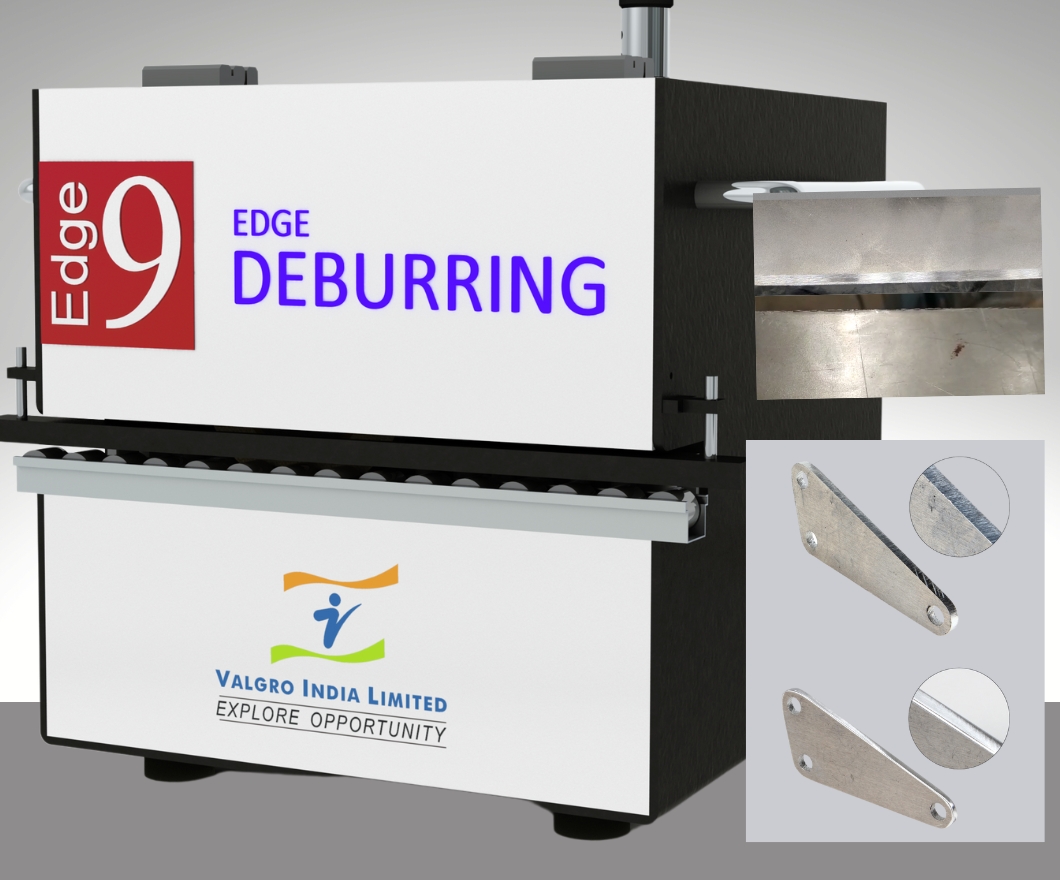

- Cut sheet edge burr removal

- sheet Metal Fabrication shop products

-

Sheet Metal Edge Deburring

Removal of burrs from cut or sheared sheet metal edges. -

Post-Shearing Edge Preparation

Surface and edge refinement after sheet metal shearing. -

Punching Burr Removal

Cleaning up edges after punching operations. -

End-Edge Polishing for Safety and Finish

Improving both appearance and worker safety by eliminating sharp or rough edges.