Valgro-SLR Series machines are perfect for removing burr and scale from laser-cut parts, as well as replacing chipping and manual grinding operations. Valgro India sets standards in revolutionary sheet metal processing with highly effective methods. It is perfect for deburring and edge rounding of punched, laser, and high-definition plasma cut workpieces since it requires just one work procedure. It efficiently saves up to 60% of operational expenses.

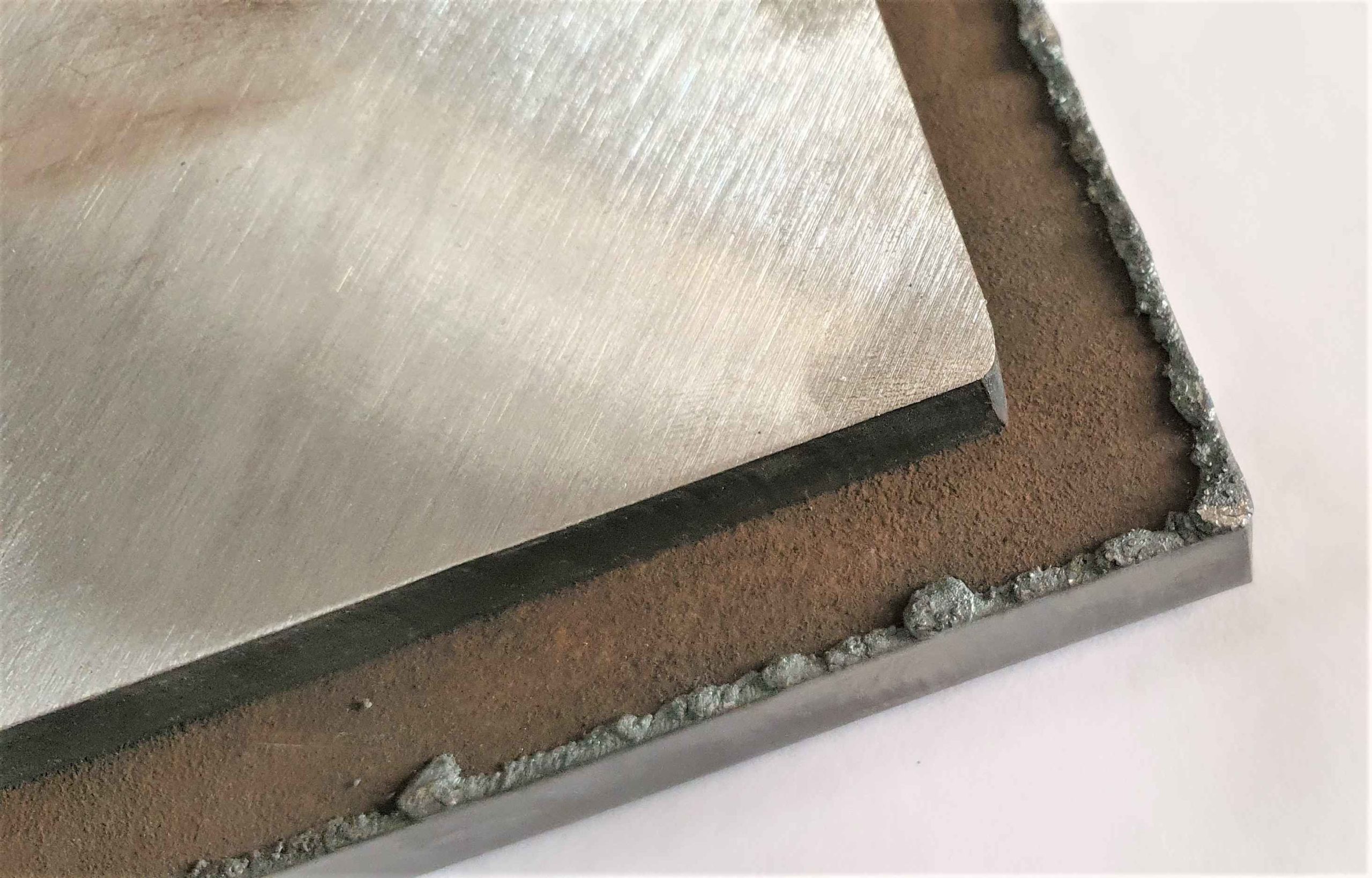

- Deburring and Edge radius on laser-cut component

- Grinding and calibration with many heads

- Multihead deburring and Edge rounding

- Strong and high-tech System

- Wet dust extraction system (Optional)

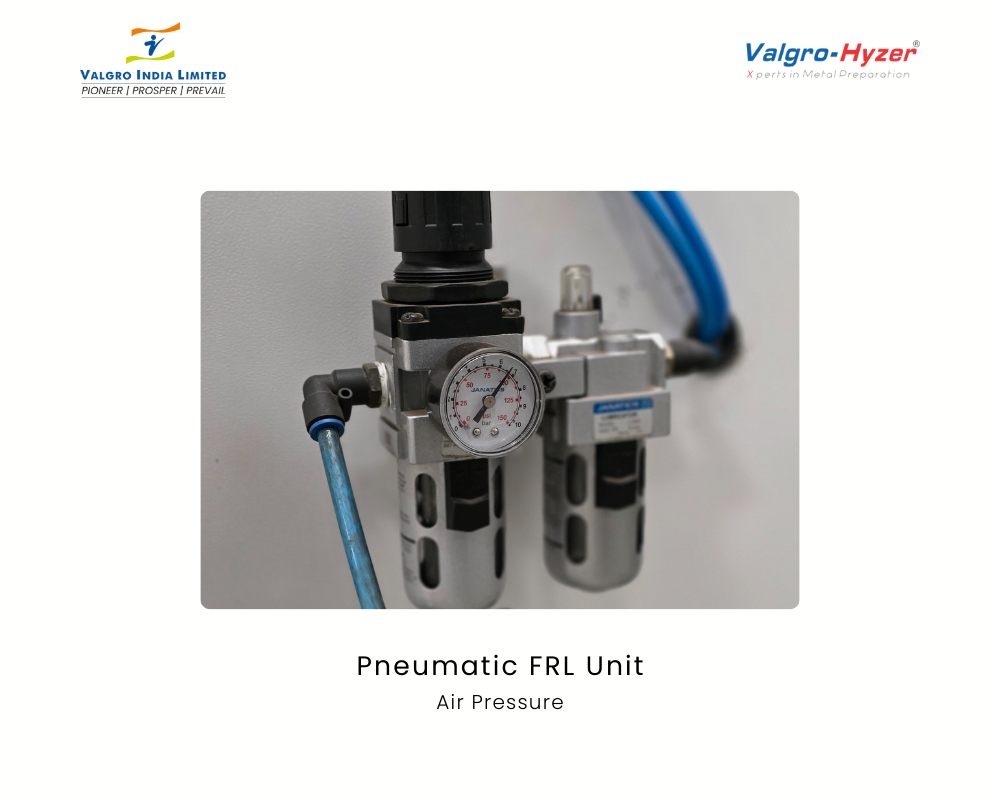

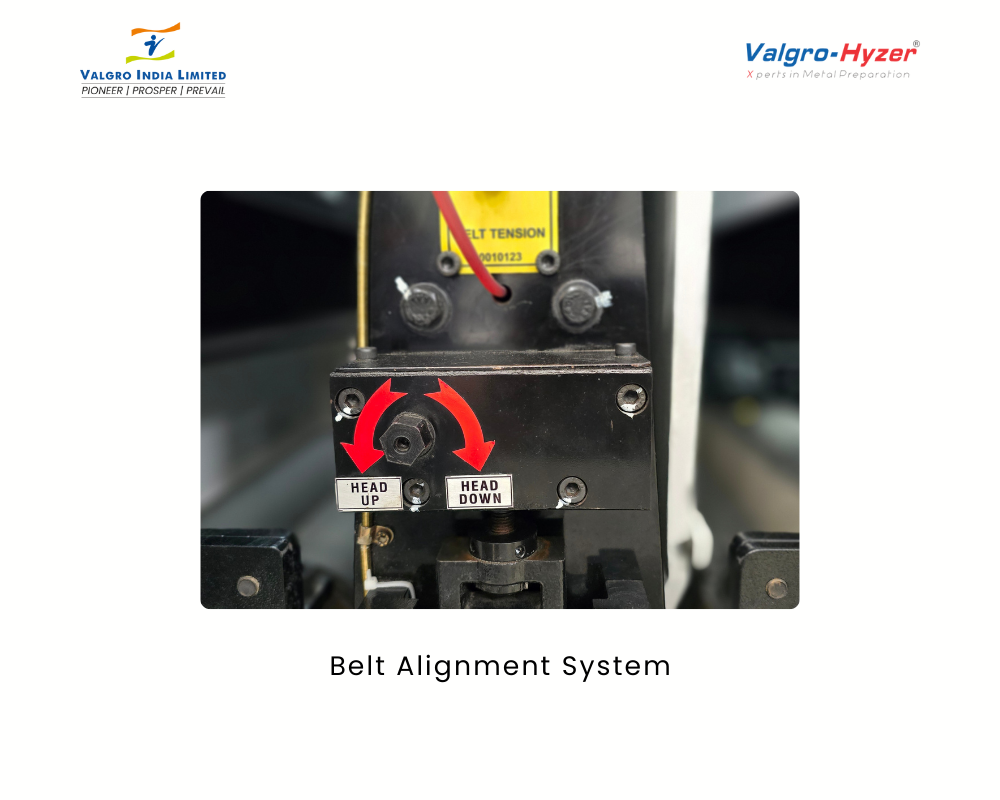

- Stations with adjustable pressure

- Simple and easy brush replacement

- Belt/roller conveyor speed adjustment

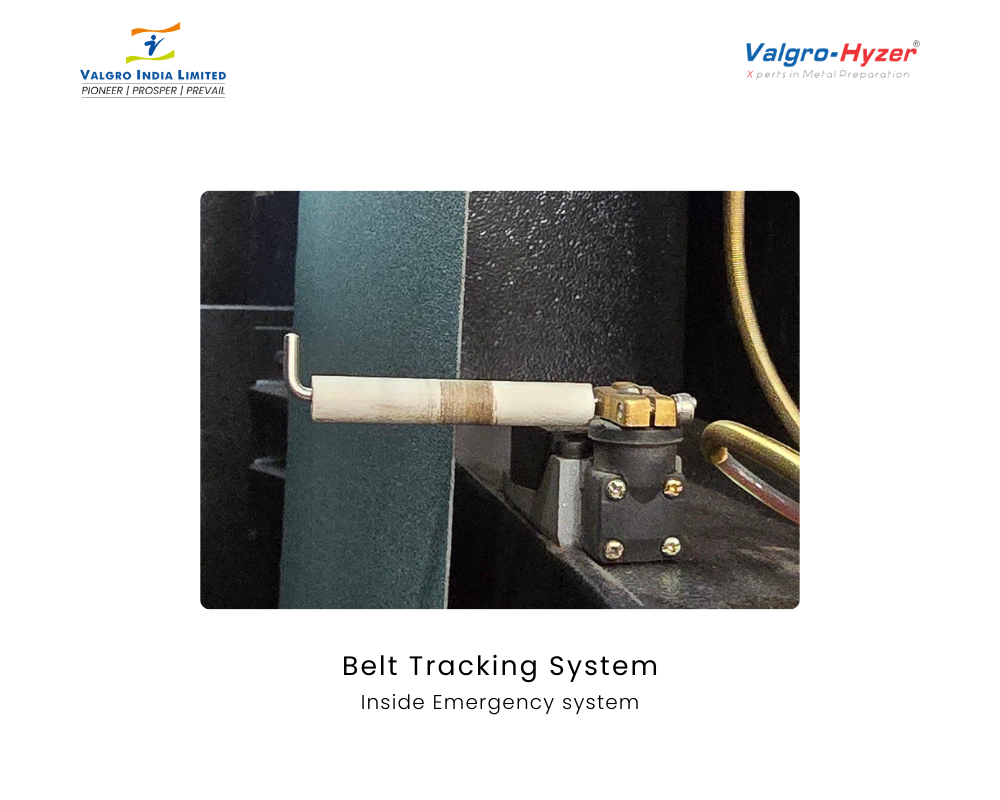

- Emergency alarm

- Conveyor emergency reverse

The Valgro SLR Series is designed for sheet metal surface preparation, deburring, and finishing. This series focuses on consistent and efficient surface processing, typically for laser-cut, punched, or sheared sheet metal parts. Here are the key technical functions and features:

1. Sheet Leveling & Removal

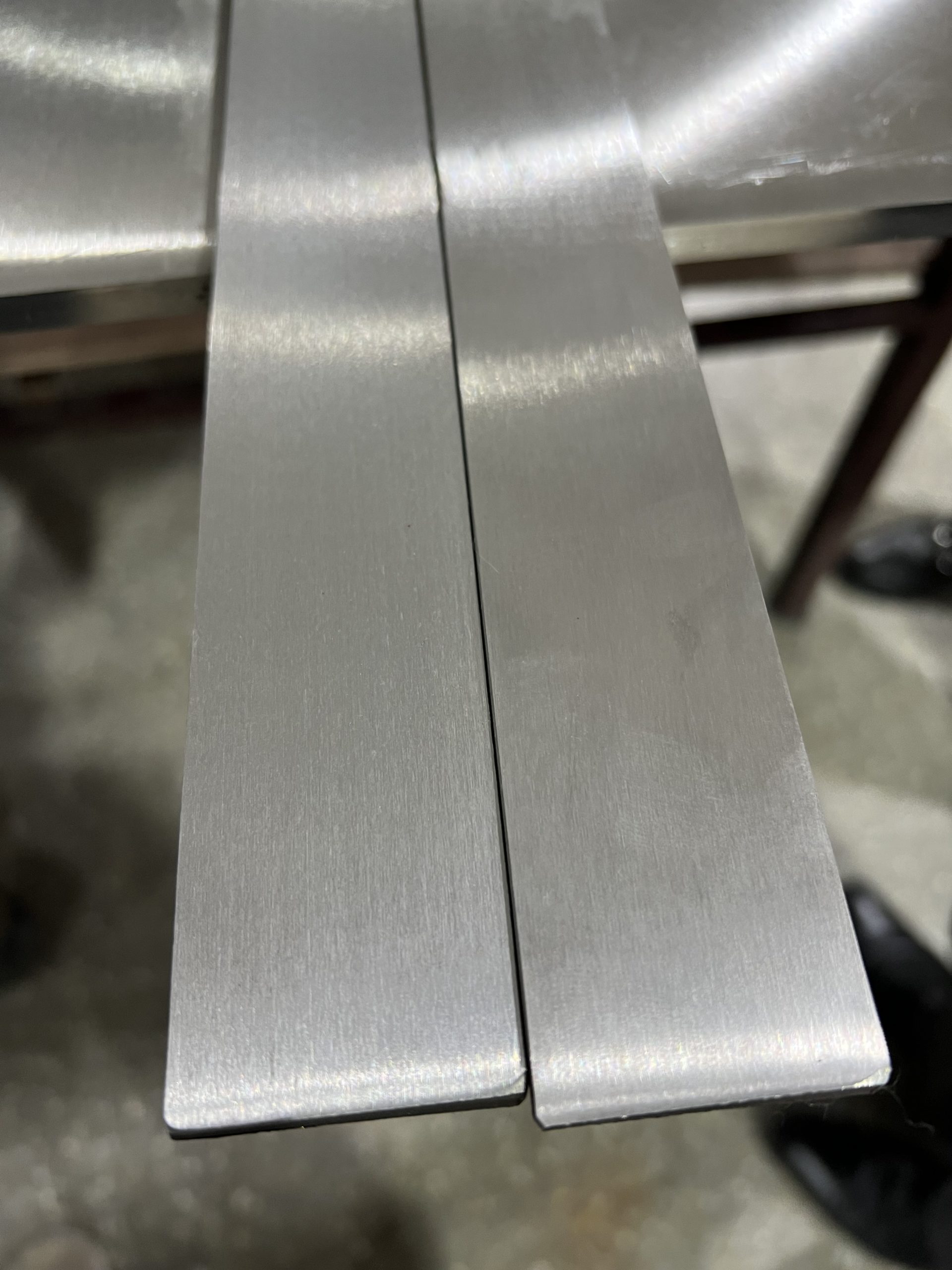

- Precision Deburring: Removes burrs from the edges of metal sheets, ensuring smooth edges after laser cutting or punching.

- Surface Finishing: Provides uniform surface finishing, improving the aesthetics and functionality of the sheet metal.

2. Multi-stage Process

- Wide Belt Grinding: Equipped with abrasive belts to grind and remove oxidation, surface defects, or unevenness.

- Rotary Brush System: Helps achieve a soft finish while deburring the edges and corners, ideal for smooth surface requirements.

- Oscillating Brush Head: Ensures full coverage of the workpiece by using a back-and-forth motion for uniform deburring.

3. Variable Speed Control

- Allows fine-tuning of the speed of the belt and brush for different materials and finishing requirements, making it versatile for various metal types such as steel, stainless steel, aluminum, and copper.

4. Modular Design

- Can be customized based on the needs of the production line, including the addition of deburring, grinding, or polishing modules, making it flexible for different metal processing tasks.

5. Dust Collection Integration

- Features integrated or compatible dust extraction systems to maintain a clean working environment and improve operator safety.

6. Pressure Sensors

- Equipped with pressure sensors that automatically adjust the pressure applied by the abrasive belts or brushes, optimizing the processing for various thicknesses of sheet metal.

7. High-Precision Material Handling

- Uses precise material handling systems to ensure consistent contact between the sheet and the processing tools, reducing the chances of error or inconsistent finishing.

8. Touchscreen Control Panel

- Features an easy-to-use control panel with programmable settings for different job profiles, ensuring a user-friendly operation and quick adjustments between tasks.

These technical functions make the Valgro SLR Series an advanced solution for high-precision sheet metal finishing, ideal for industries where surface quality and edge preparation are critical.

- Deburring punched, nibbled, sheared, or laser-cut sheet metal parts.

- Deburr and sand a radius to the sharp edge on cut-out parts

- Uniform sanding on all edges, leaving a fine finish on the surface with different abrasive belt grit.

- Deburring of all edges in one pass on laser cut or stamped parts.

- Grain finishing on any material.

- No chipping or power tool use.

- 10x Faster job.

- Reduce manpower with uniform deburring and finishing without defect