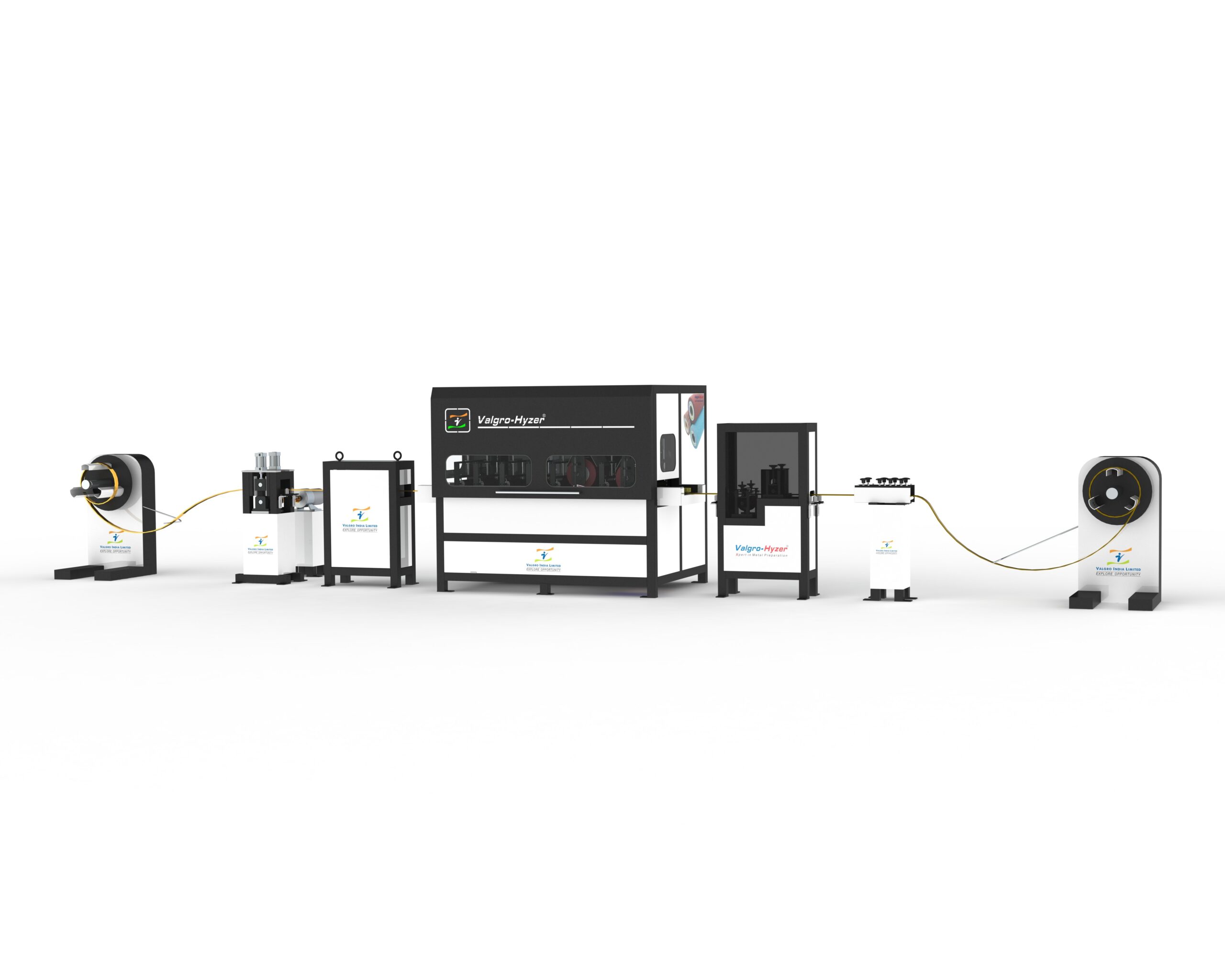

Valgro’s High-Gloss Mirror Polish Line is the latest innovation in metal finishing, designed for continuous polishing of strip coils. The line offers unmatched precision, high throughput, and energy efficiency. Its modular design allows customization to meet specific production requirements. Equipped with automated controls and advanced abrasive systems, this line guarantees a flawless, mirror-like finish suitable for high-end applications.

High-Precision Polishing

- Achieves uniform high-gloss mirror finishes.

- Consistent surface quality across the entire strip coil.

Advanced Abrasive Technology

- Uses premium abrasive belts and brushes for superior results.

- Adjustable grit and polishing sequence for different materials.

Automation and Control

- Integrated PLC-based control system for seamless operation.

- Real-time monitoring and parameter adjustments.

Efficient Design

- Modular construction for easy maintenance and upgrades.

- Energy-efficient components to reduce operational costs.

Durable Build

- Engineered with robust materials for extended service life.

- Designed to handle heavy-duty, continuous operations.

Line Specification:

- DE-coiler Pay Off

- Straightener

- Strip Tension system

- Edge Rounding Unit

- Coiler: Take Off

Architectural and Decorative

- Polished strips for decorative panels, trims, and fittings.

Automotive

- High-gloss components for interior and exterior applications.

Electronics

- Precision-polished materials for electronic casings and connectors.

Kitchenware and Utensils

- Premium finishes for cookware and appliances.

Aerospace

- Reflective materials for high-performance applications.