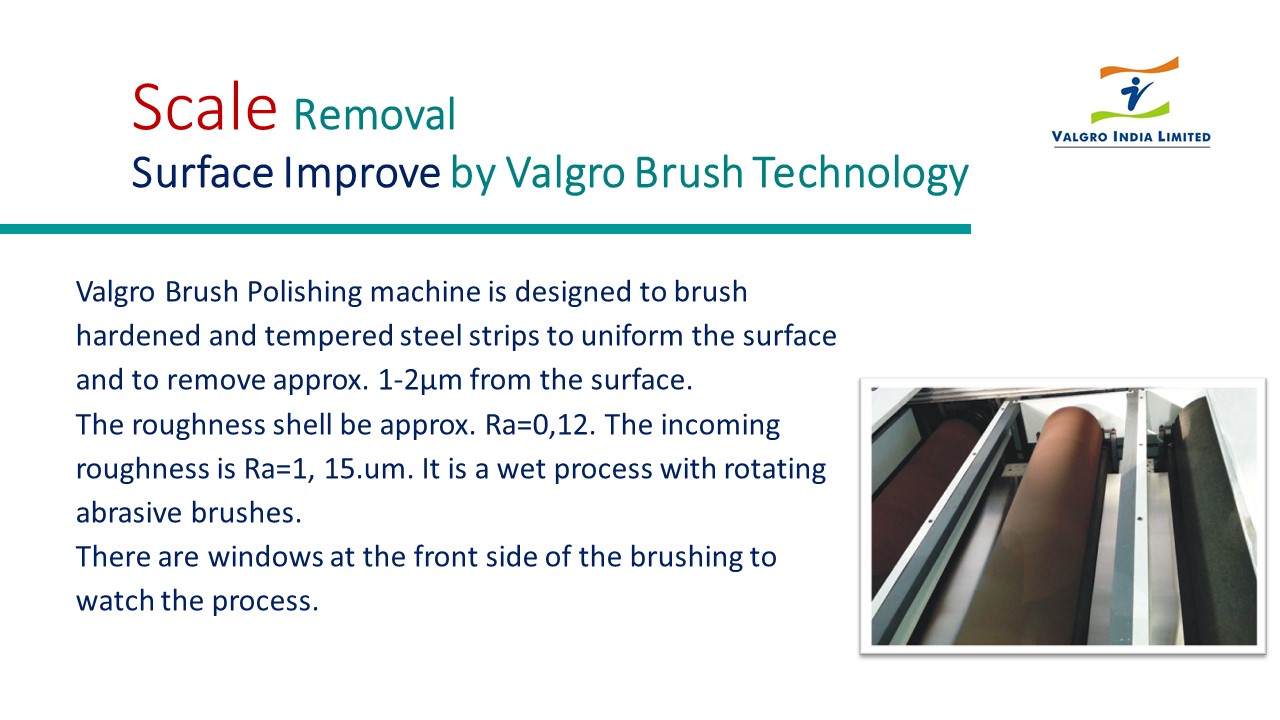

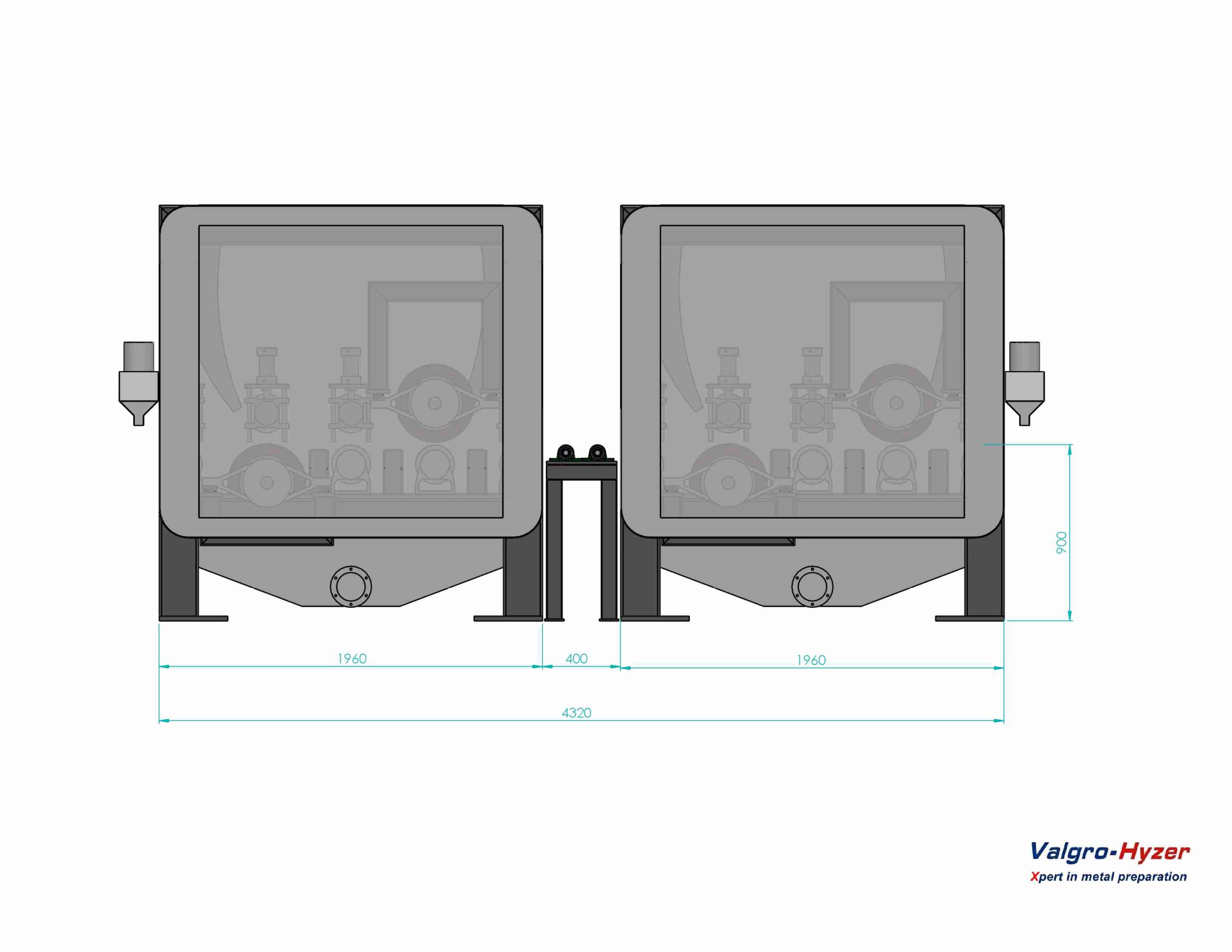

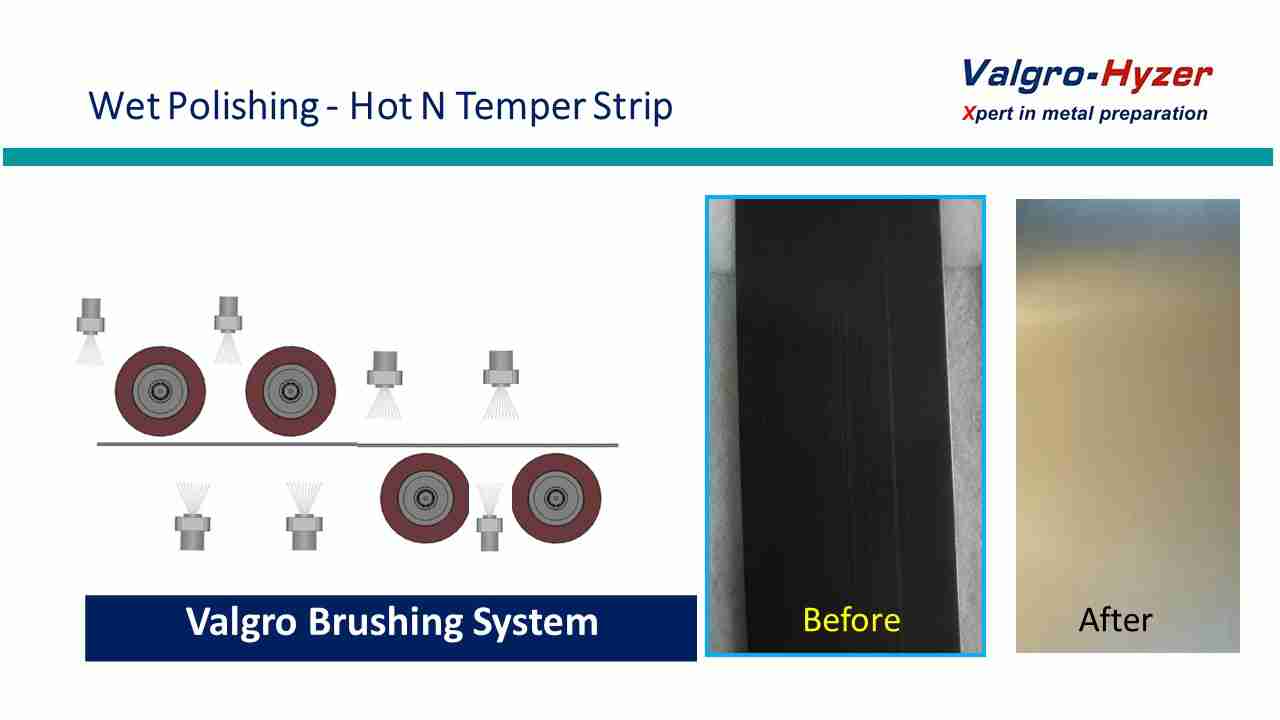

The brush machine is consisting of a brushing of a brushing chamber and a machine housing. The machines housing carries the spindle system. Drive system and adjustment system. The brush chamber is sealed to the machine housing. There are windows at the front side of the brushing to watch the process.

Feature :

- Faster Production

- More shine surafce

- Less Power require

- Stardy and Robust Design

Benefits :

- Vibration free uniform surface

- Consistent result from 1st meters to last running meters

- No strip Deformation – No Camber

- Cool running – Smooth running

- Less then 80 DB noise level at brushing machine

- Reduce power consumption – energy saving

- Increase Profit – Reduce Polishing cost

- Supper bright Finish

- Environment free polishing work

Technical Specification

customize solution

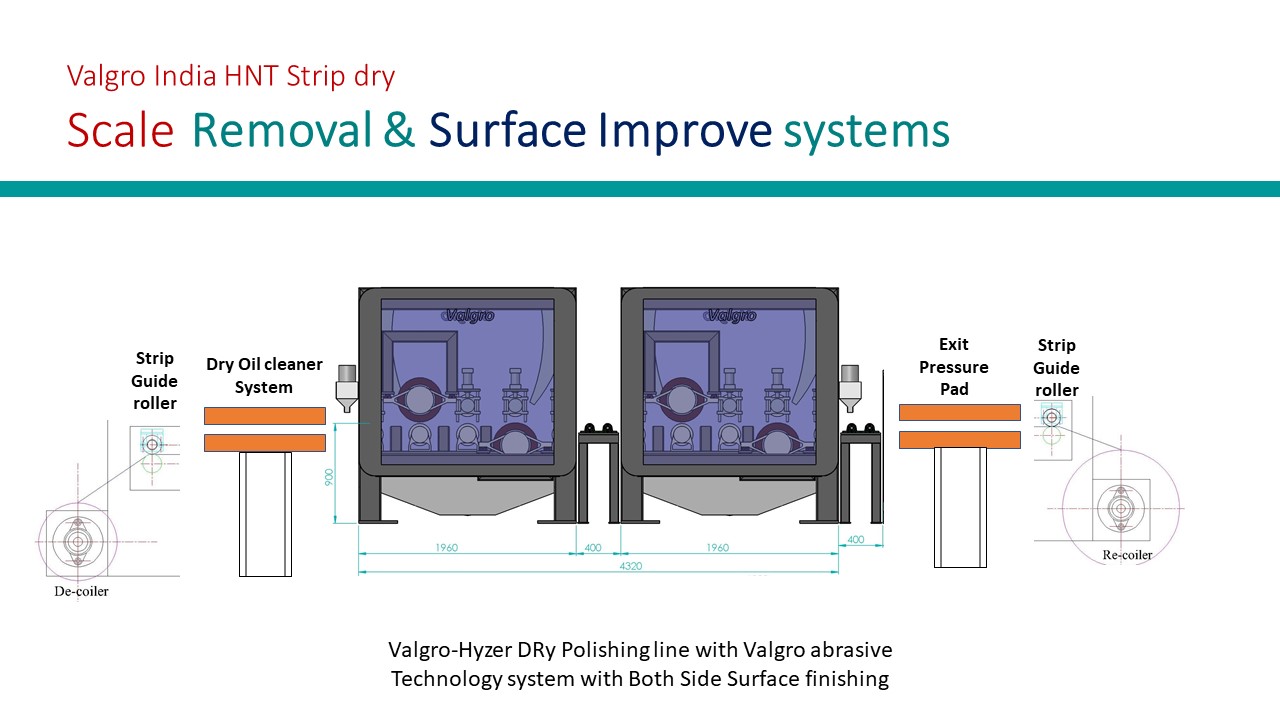

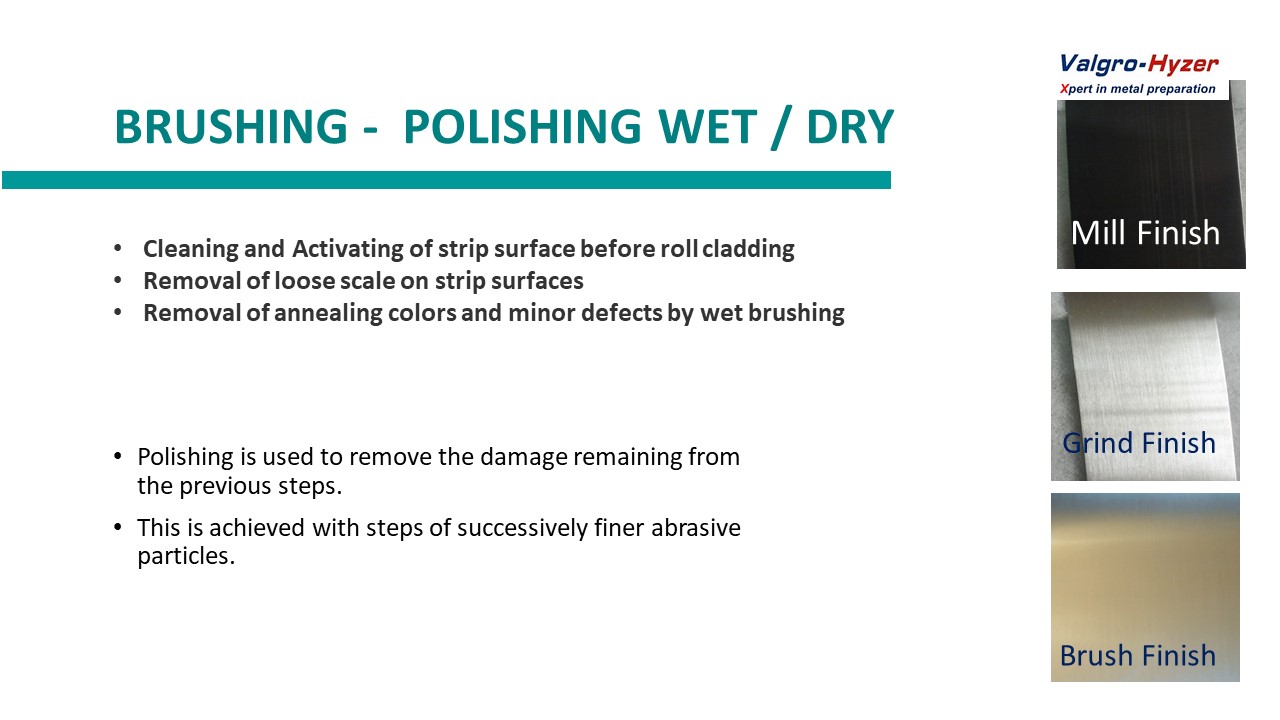

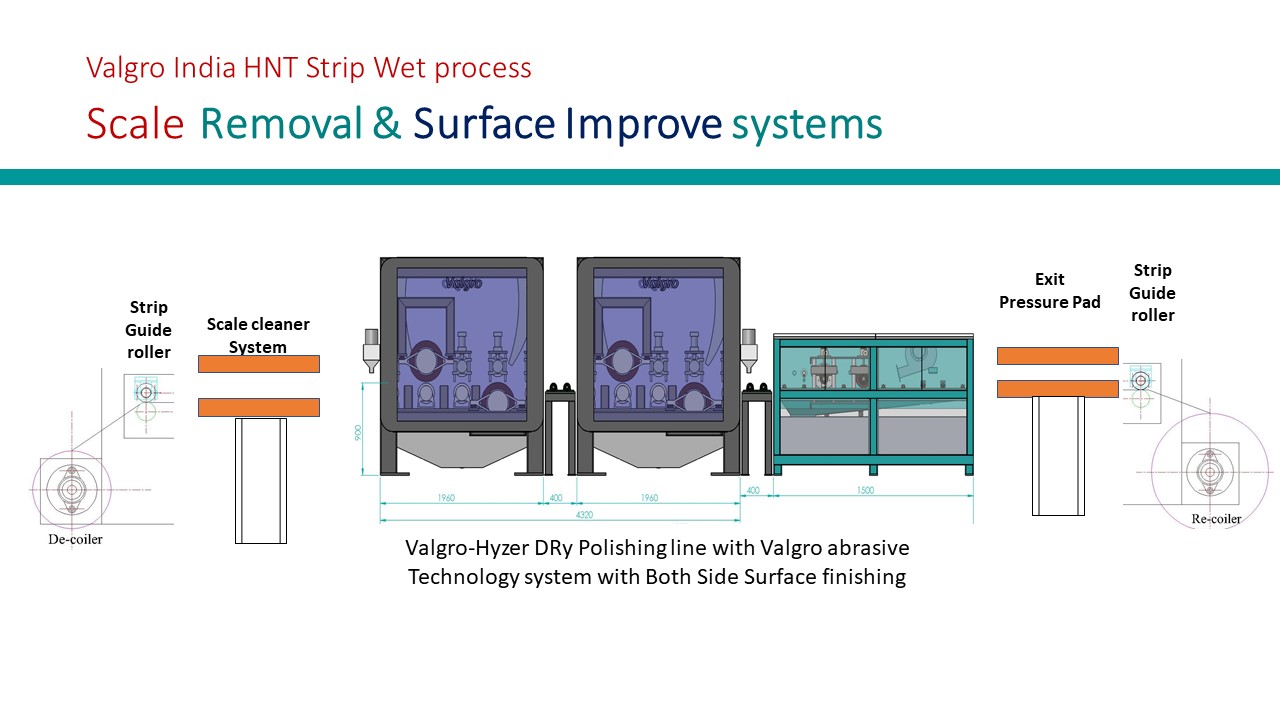

- During processing of heavy plates in a cut to length line a lot of scale will form loose parts during bending and deflecting of the strip surface. This scale causes dirt contamination in the following aggregates (flattener, shear, etc.) and increase the downtime due to frequent cleaning cycles.

- VALGRO has developed a heavy duty wet brushing machine, especially for this application, i.e. removing of loose scale from the surface.

- A combination of rotating brushes and high efficient exhaust system form the key equipment of this machine