Safety attention to in the polishing process

What should be paid safety attention to in the polishing process of the polishing machine

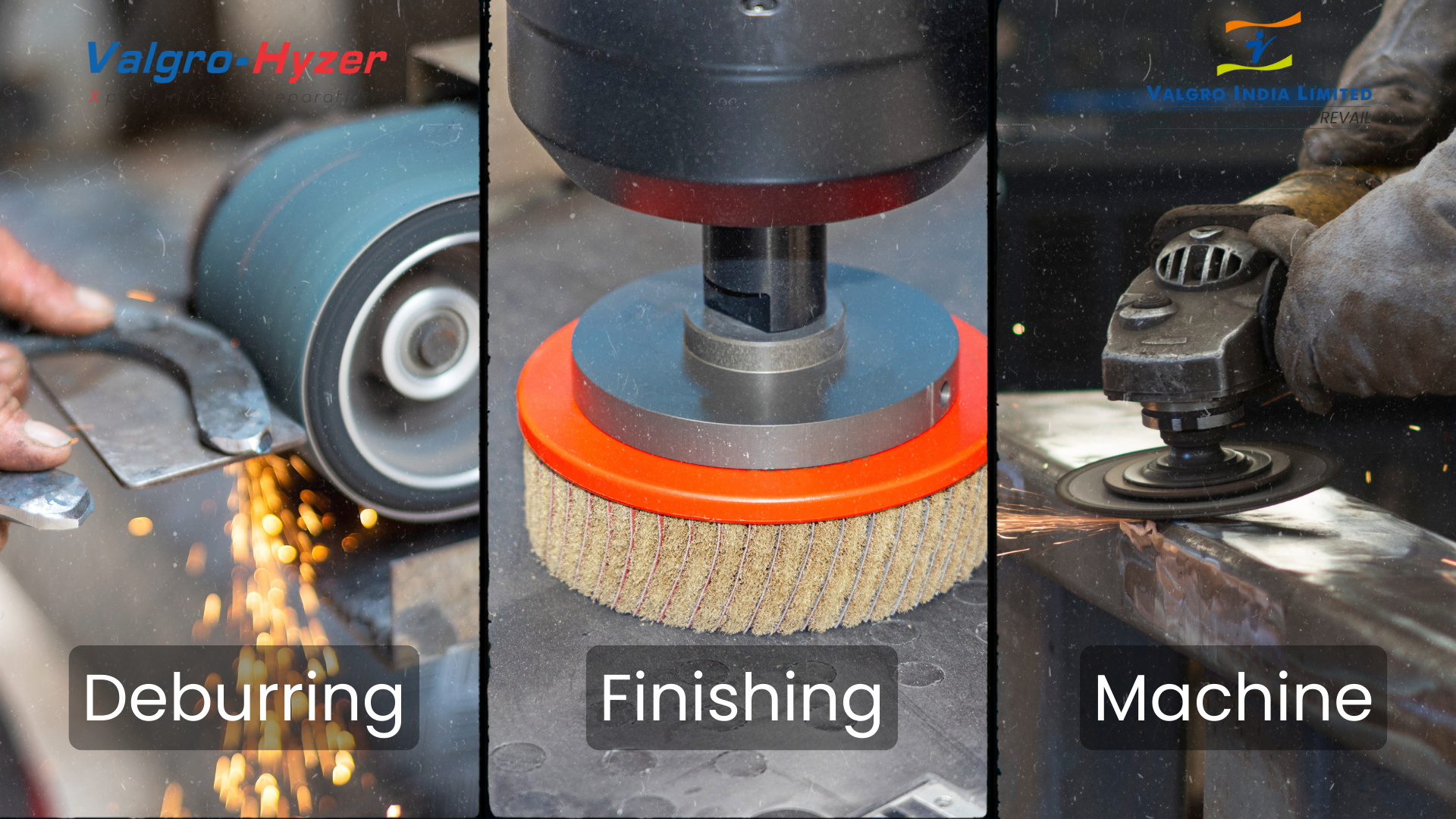

A polishing machine involves rotating elements like the Motor to Pulleys to the Spindle shaft and further to the Abrasive & Buffing Wheels. These operate Wheels at extremely high RPMs. To add to it is the lateral movement of the Table with the Component clamped onto it.

Besides achieving our desired results from Machine, Safety becomes a priority here.

The following points should be paid special attention to:

1. Clamping of the workpiece should be done correctly as it involves lengthy & Heavy components with Vector loads acting on the Workpiece. Do not try holding the Workpiece by Hand when in process.

2. It is necessary to prevent the foot from being hurt if the parts fall off. During operation, both feet must be protected by a protective frame, the style of the protective frame is shown in the figure.

3. Avoid loose clothing & glove during operation. During the operation, the contact surface between the fingers and the parts must be insulated with hand pads, and gloves must not be worn to avoid accidents caused by the parts around the gloves.

4. If the part falls off during operation, Switch “OFF” the machine. Once it is stopped proceed to pick up the Workpiece. Shutting down first is to avoid accidents caused by touching the rotating polishing wheel during picking up.

5. Shut down the machine immediately, if the workpiece goes around the runner during operation, it may be thrown out and an industrial injury accident may occur. In addition to shutting down leave the scene immediately.

6. Fire protection is of particular importance during the polishing process. The velvet thrown off the cloth wheel during polishing may get ignited due to excessive heating & sparks produced by the polishing of the parts. This phenomenon though may be rare but cannot be ignored and due vigilance is a must.