Introduction:

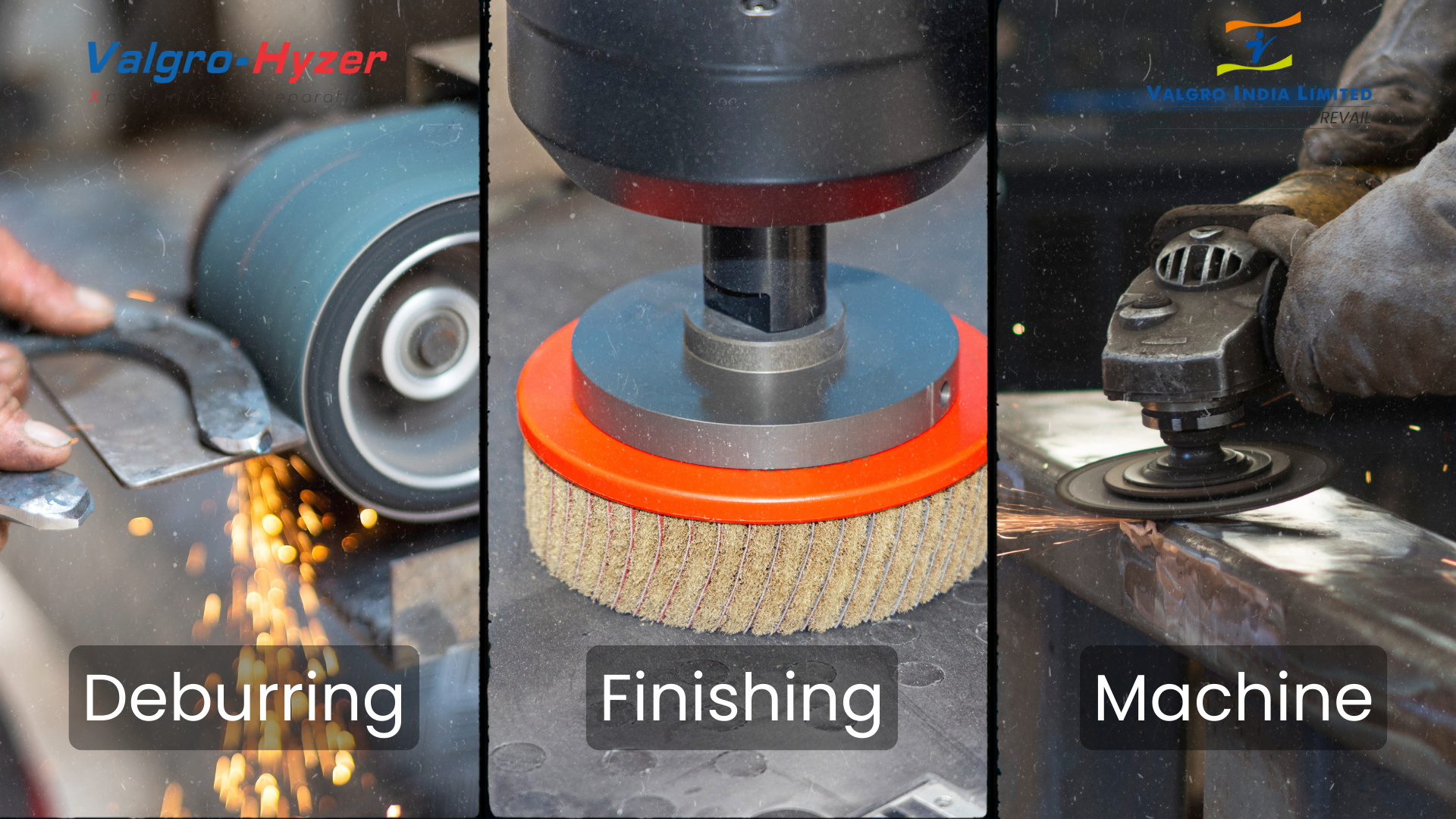

Metal manufacturing requires the greatest quality and usefulness of #metal products. This method relies heavily on #deburring and #finishing equipment. This article delves into the main function of these machines and their influence on metal manufacturing.

Background on Metal Fabrication:

Metal fabrication includes a variety of operations, including cutting, drilling, milling, and stamping, to make metal parts and components. Although these procedures are necessary for shaping metal, they often leave behind flaws such as sharp edges, ridges, and burrs. Imperfections may impact the end product’s performance, safety, and aesthetics.

Purpose of Deburring Machines:

1. Remove burrs and sharp edges. Deburring machines target burrs, which are tiny, raised edges or protrusions left on metal objects after machining. Burrs are sharp and potentially dangerous to workers, increasing the risk of injury during handling and assembly.

2. Enhancing safety By eliminating sharp edges and burrs, deburring machines contribute to a safer working environment. This decrease in sharp edges reduces the chance of cuts and accidents, which improves overall job safety.

3. Improving functionality Deburring machines improve the functionality of metal components. Burrs and sharp edges may disrupt the appropriate fit and operation of components, resulting in assembly problems and poor performance. Deburring machines aid in the proper assembly and operation of components by guaranteeing clean edges.

4. Ensuring consistent quality Deburring machines provide a consistent and uniform finish, which is critical for meeting high-quality requirements. Automated deburring procedures guarantee that all parts get the same amount of treatment, eliminating differences and flaws in the finished #product.

Purpose of Finishing Machines:

1. Enhancing the surface finish Metal components use finishing machines to improve their surface properties. Polishing, buffing, and grinding produce a smooth and aesthetically pleasing surface. This upgrade is cosmetic and useful, as a well-finished surface may minimize friction and wear.

2. Increased durability. Finishing methods often include the application of protective coatings or treatments to improve the durability and lifetime of metal products. Techniques such as electroplating and anodizing offer corrosion resistance, extending the life of the components.

3. Meeting specific tolerances and specifications. Finishing machines provide fine control over #surface texture and proportions. This capability is critical for meeting the tolerances and criteria required for high-precision aerospace or medical equipment applications.

4. Enhancing aesthetic appeal. Finishing machines not only provide practical advantages, but they also improve the aesthetic attractiveness of metal products. A polished or buffed surface may greatly enhance the look of consumer goods, ornamental objects, and high-end technology.

#deburring #finishing #polishing #machine #descaling #metalfabrication #metalforming #sheetmetalfabricator