In 1991, I was struggling to survive. Our lower-middle-class family faced a financial crisis after my father lost his job. A deep recession had hit textile industries worldwide, resulting in the closure of many textile mills. The industry in India found itself in a deeper crisis because of the intensifying global competition fueled by newer technologies and fast-paced innovation. Our textile industry lacked the adequate capabilities to counter this challenge. Many companies had to stop production. During this time, I started a small trading firm for the supply of industrial products. It was a small setup. By 2005, the start-up had grown into a company called Valgro Engineers Private limited, which imported abrasives from Europe.

In 1991, I was struggling to survive. Our lower-middle-class family faced a financial crisis after my father lost his job. A deep recession had hit textile industries worldwide, resulting in the closure of many textile mills. The industry in India found itself in a deeper crisis because of the intensifying global competition fueled by newer technologies and fast-paced innovation. Our textile industry lacked the adequate capabilities to counter this challenge. Many companies had to stop production. During this time, I started a small trading firm for the supply of industrial products. It was a small setup. By 2005, the start-up had grown into a company called Valgro Engineers Private limited, which imported abrasives from Europe.

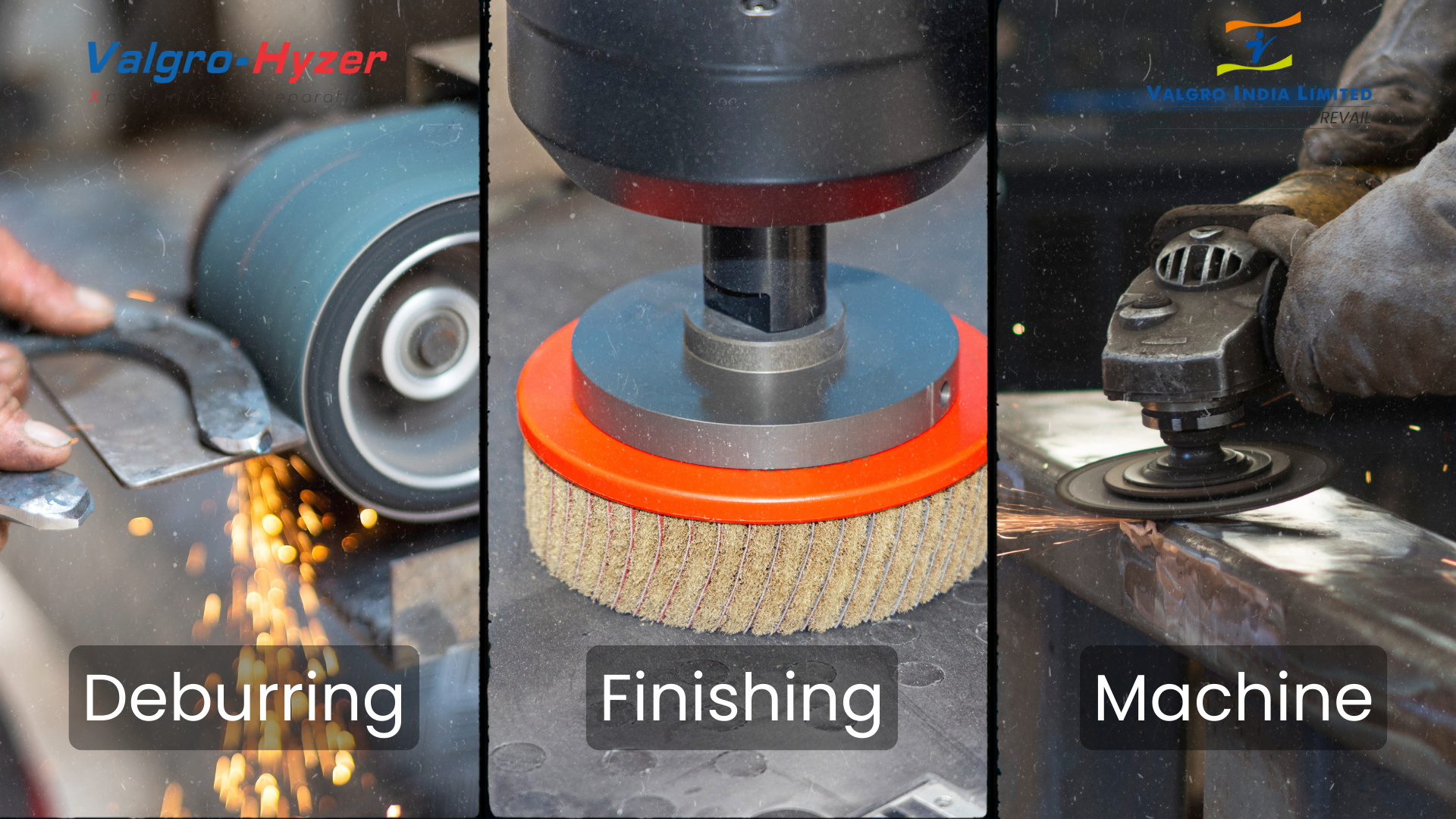

In 2009, we started the production of surface conditioning abrasives under the brand name VALGRO. Thanks to an increased demand for our supplied products, we established a well-known brand very fast in the metalworking industries for the surface conditioning applications to be used for the machining process. We have gained a leadership position in offering a value finish with the edge-rounding of machines, without any material deformations and deviation in the dimension – a value offering that is highly prized in the high-precision engineering industries.

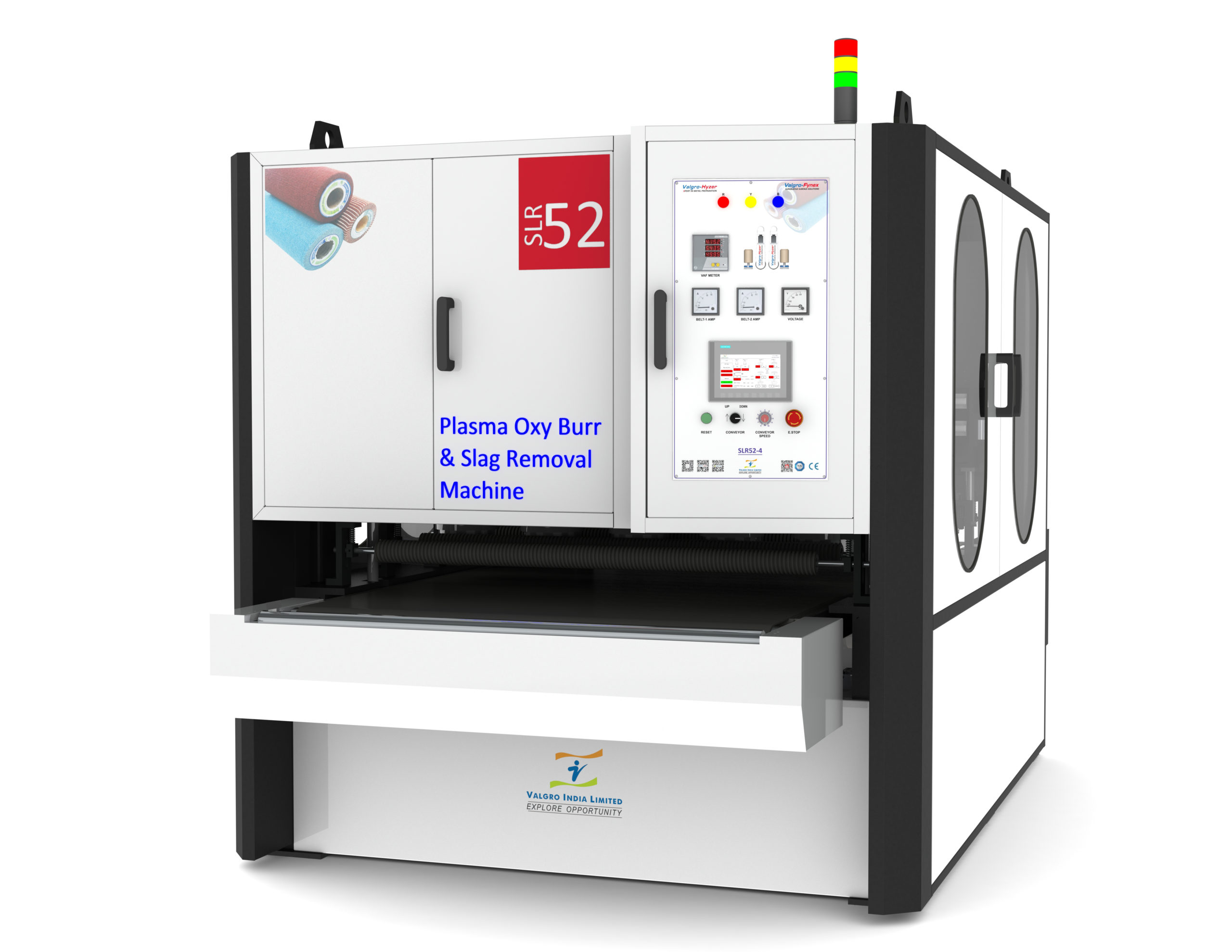

To expand our abrasive business, we established Valgro India Ltd, our machine-building division, in 2015 for the manufacturing of metal finishing machinery with a high-precision technology that matched German-standard yet was affordable for even midsize Indian companies.

Today we offer a whole range of renowned brands in metal finishing machinery and abrasives brush and wheel. Valgro India is a fast-growing company. The reason for our success is our focus on customer-centricity. This is what we are going to demonstrate to our present and potential customers who will visit us at IMTEX Forming 2022 – that we provide international-standard metal-finishing machines at affordable prices in India.