Valgro Retrofit Scale Removal Brushing Machine l Dr. Arvind Patel

Valgro India Limited introduces a retrofit Scale removal brushing machine to increase productivity and save your time and money by reducing your acid cost and faster production.

Field of the Invention: Valgro EPMS (ECO PICKLED METAL SURFACE) Retrofit Brushing Machine

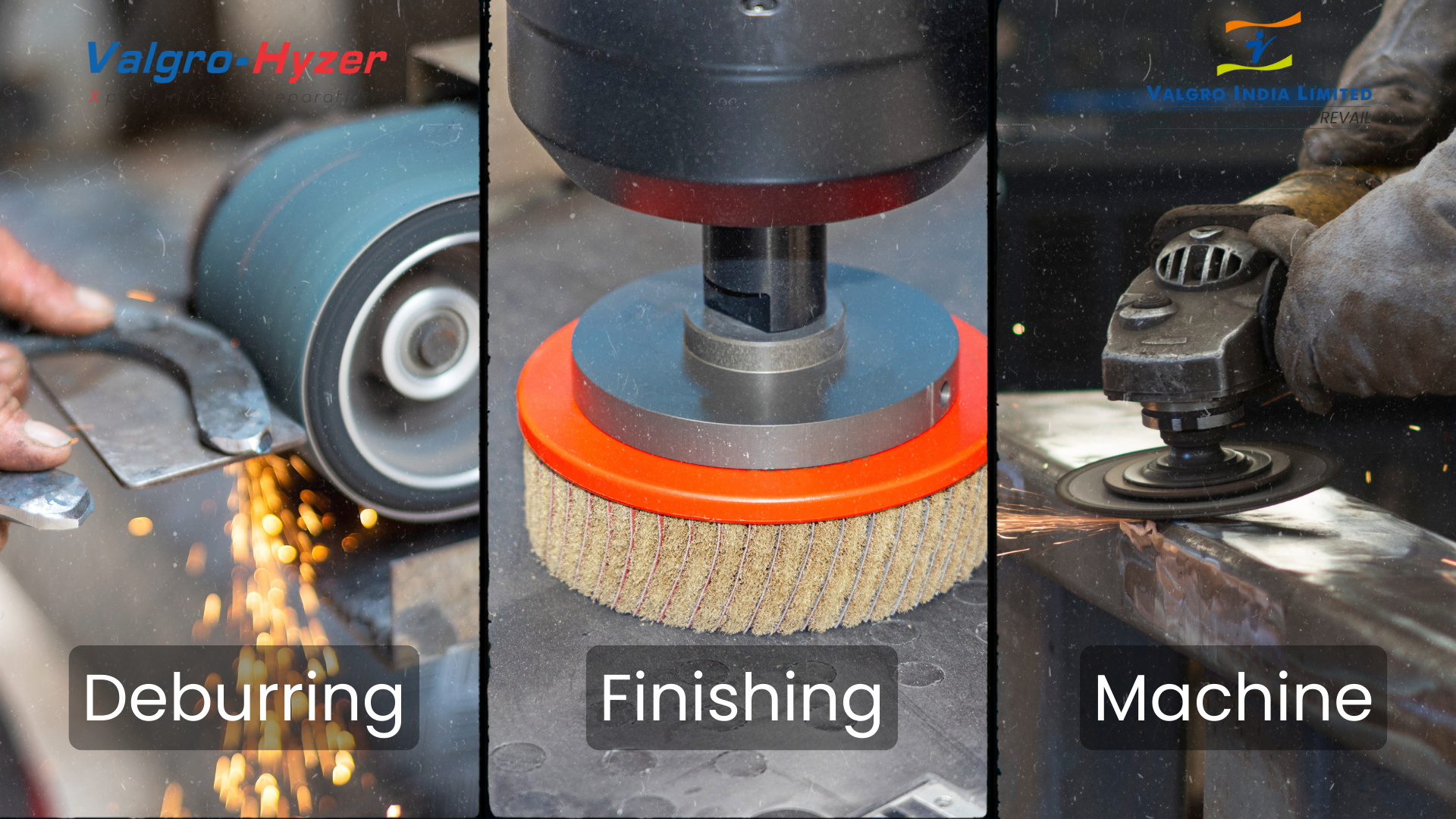

The present invention method relates to the production and finishing of metal surfaces, and more particularly to the removal of scale from the metal surfaces, e.g., surfaces of metal sheets. More particularly the present invention relates to a novel method for removing annealed scale, rust, oxide, mill scale, and oil patch, black Shot/patch from hot rolled and cold rolled. The novel process creates an ideal surface for paint adhesion, especially on CRC & stainless steel. In addition, it preps the steel better than any acid chemicals currently available for wash systems. The said method is also used for the deburring, cleaning, washing, graining, de-greasing, de-scaling, finishing, and surface preparation of different kinds of ferrous and non-ferrous material by wet and dry processing. The present invention is a novel method for the preparation of metal surface we call ECO PICKLED METAL SURFACE – EPMS

Through our continuous research and development efforts, we can make heavy-duty unique retrofit Valgro process technology that will remove scale or oxide by mechanical process up to 75%.

The VALGRO Unique working system is a mechanical brushing system combination with Flexible abrasives steel roller wire brush, and normal hot and cold water. That improves the hot rolled black strip, making it a better base material for fabrication and OEMs.

Our filed trial has provided that saving on pickling chemical consumption to the tune of up to 60% to 70%.

Reducing scale or oxide load on chemical immersion tank can easily obtain higher productivity to the tune of 2 to 51 %

Normally pickling is carried out to prepare (remove scale or oxides) the steel surface for the next process at cold rolling. The oxide scale is required to be completely removed from not rolled steel, strip before subsequent cold rolling to prevent wear on the rolls and to avoid surface defects in the cold-rolled products.

Pickling is the most common several process used to remove the scale or oxide from the carbon steel strip surface the term pickling refers to the chemical removal of scale by immersion in an aqueous acid solution most common acid used in recanting lines is HCL.

Disadvantages of HCL acid pickling are

- Generation of tomes when heated above ambient temperature which will cord surrounding steel structure equipment leading high maintenance cost.

- Acid Recovery Systems are Expensive.

- Higher Disposal Cost

- Quality of surface is not acceptable from industries standard

VALGRO EPMS (ECO PICKLED METAL SURFACE) retrofitted into existing process line:

- increase the pickling process speed of a large continuous pickle line by ‘first pass’ scale removal

- replace acid tanks with VALGRO EPMS (ECO PICKLED METAL SURFACE) Brushing line

- reduce chemical concentration for normal gauge

- replace the cleaning section of a heavy gauge galvanizing line to allow the coating of hot band material directly from the hot mill. This saves the time and cost of a separate pickling operation.

Valgro EPMS: Valuable advantages

- Improved surface quality

- Smoother, more resilient paint finish

- No more rust

- Reduced paint preparation

- Smoother paint finish

- Reduce dimples on a painted surface

- Cleaner work environment

- Less rework, fewer rejects

- Faster laser/plasma cutting

For more detail, please call us with your detailed need