Aluminum profiles are widely used in various industries due to their lightweight, durability, and corrosion resistance. However, to achieve the desired aesthetic appeal and functional properties, a brush finish is often applied. Here’s why a brush finish is essential and how Valgro India can assist with their expertise:

Benefits of Brush Finish on Aluminum Profiles:

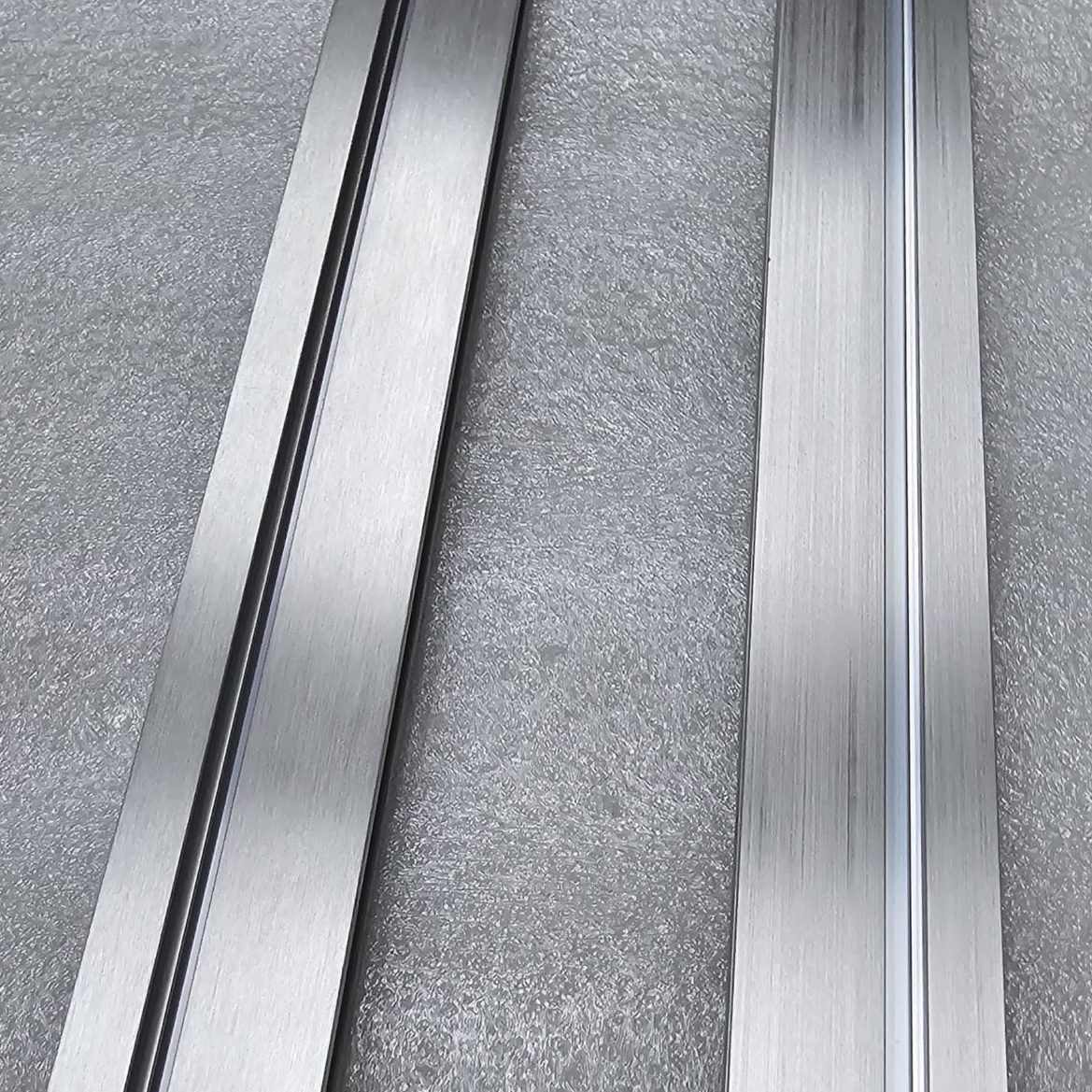

- Enhanced Appearance: The brush finish provides a sleek, uniform look that enhances the visual appeal of aluminum profiles, making them suitable for high-end architectural and decorative applications.

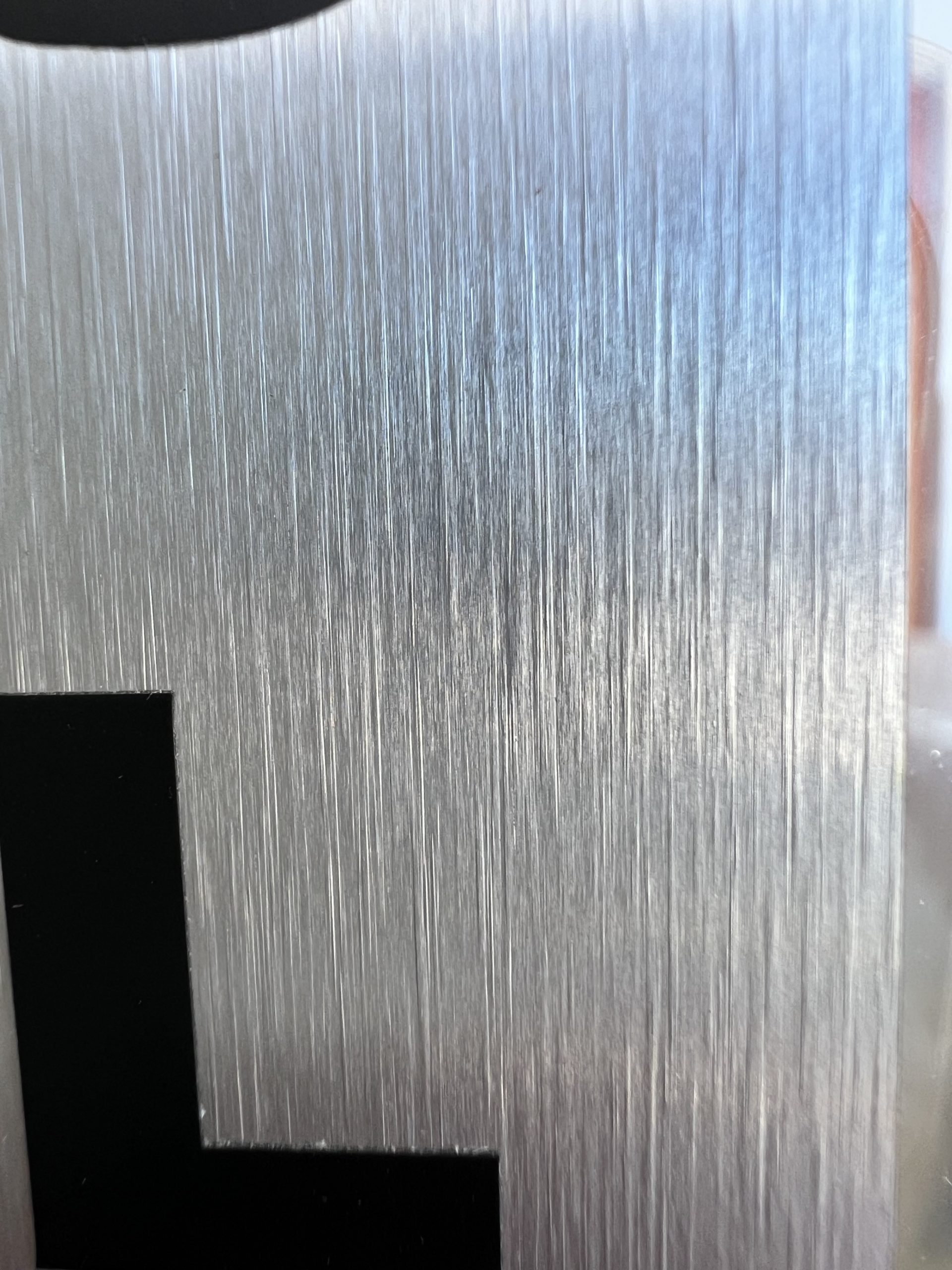

- Improved Surface Texture: It removes imperfections, scratches, and marks, resulting in a smoother surface that is more pleasant to touch and visually appealing.

- Corrosion Resistance: The process can also help in removing surface contaminants and creating a more uniform oxide layer, which enhances the corrosion resistance of the aluminum.

- Increased Adhesion: For applications where aluminum profiles need to be painted or coated, a brush finish improves the adhesion of the subsequent layers, ensuring better longevity and performance.

How Valgro India Can Help: Valgro India is a leader in surface treatment technology with extensive experience in providing high-quality brush finishing solutions for aluminum profiles. Here’s how they can assist:

- Advanced Equipment: Valgro India offers state-of-the-art brushing machines designed to provide consistent and high-quality finishes on aluminum profiles.

- Custom Solutions: Their expertise allows them to develop custom brushing solutions tailored to specific needs, whether for architectural, automotive, or industrial applications.

- Technical Support: With a team of skilled technicians, Valgro India provides comprehensive support from installation to maintenance, ensuring optimal performance of their brushing systems.

- Innovative Techniques: Valgro India continuously innovates their processes to enhance efficiency and finish quality, staying ahead in the industry.

For a detailed demonstration of their brushing solutions, check out Valgro India’s YouTube channel: Valgro India YouTube Channel