Valgro India is proud of the reputation that we have earned for quality and service. For over 30 years, we have gained a reuptation for quality work at competitive prices while meeting all of our customer’s lead time demands for both estimating of projects and delivering on time.

Features:

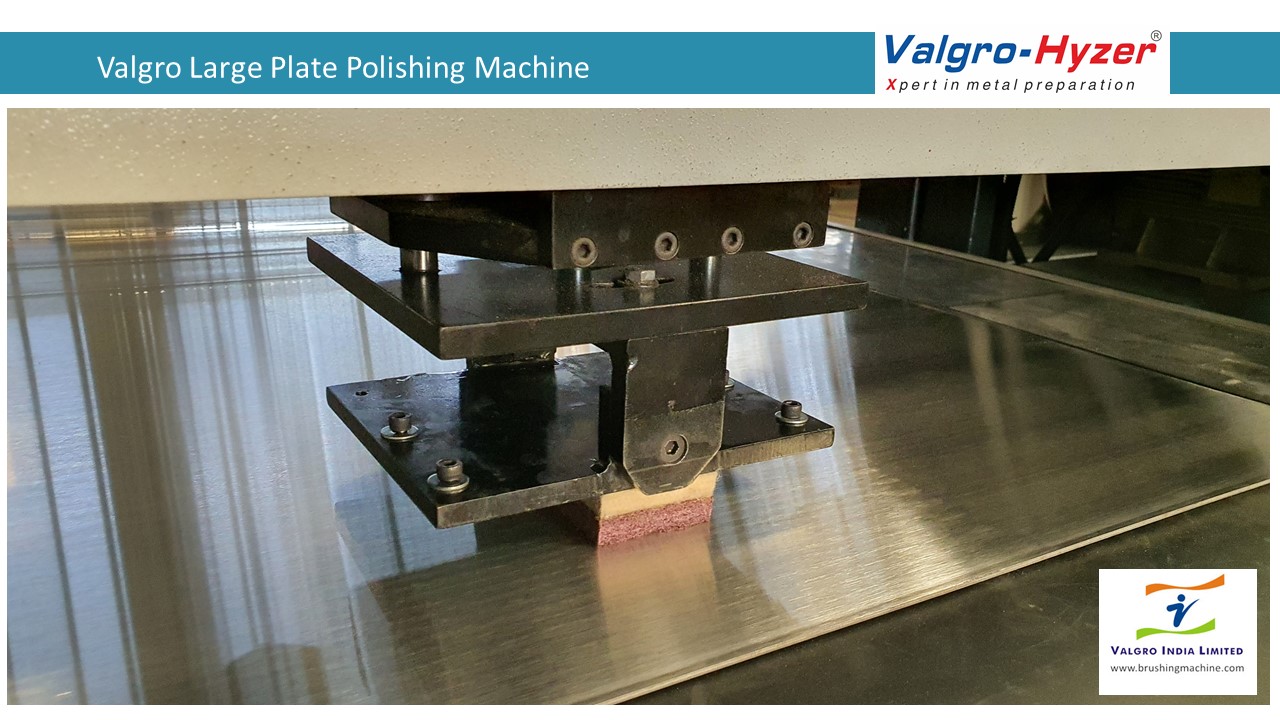

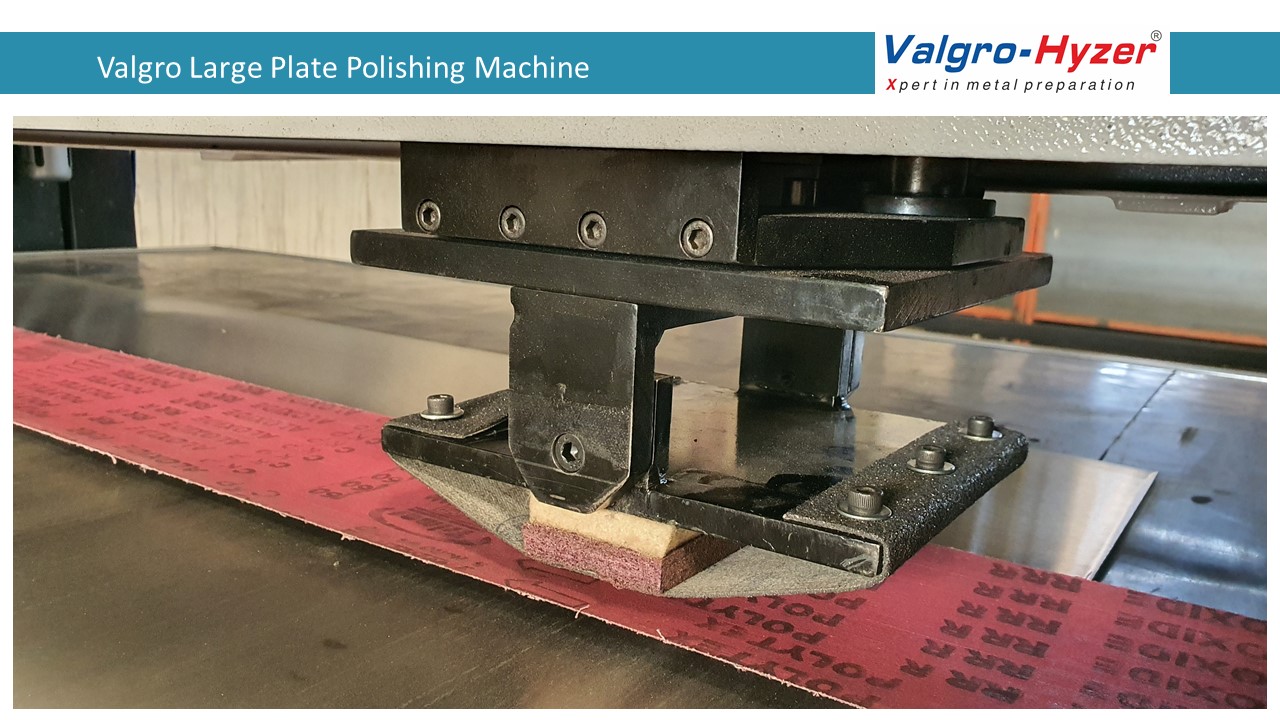

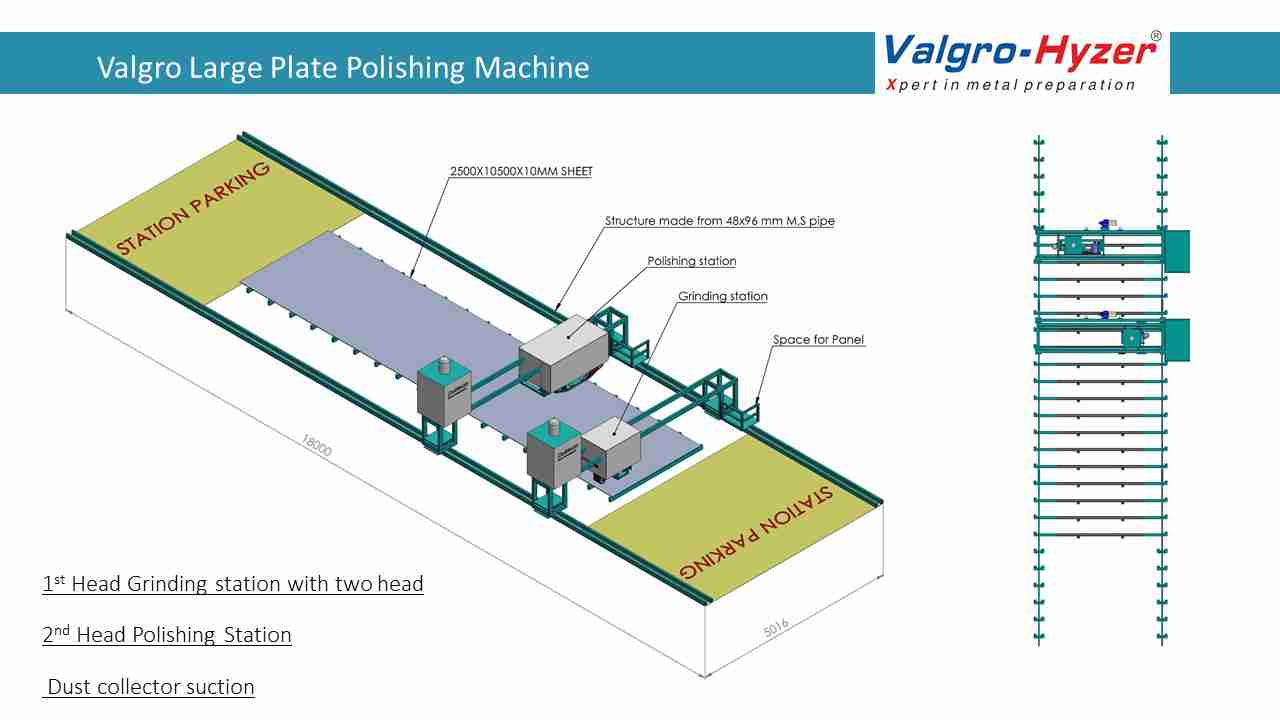

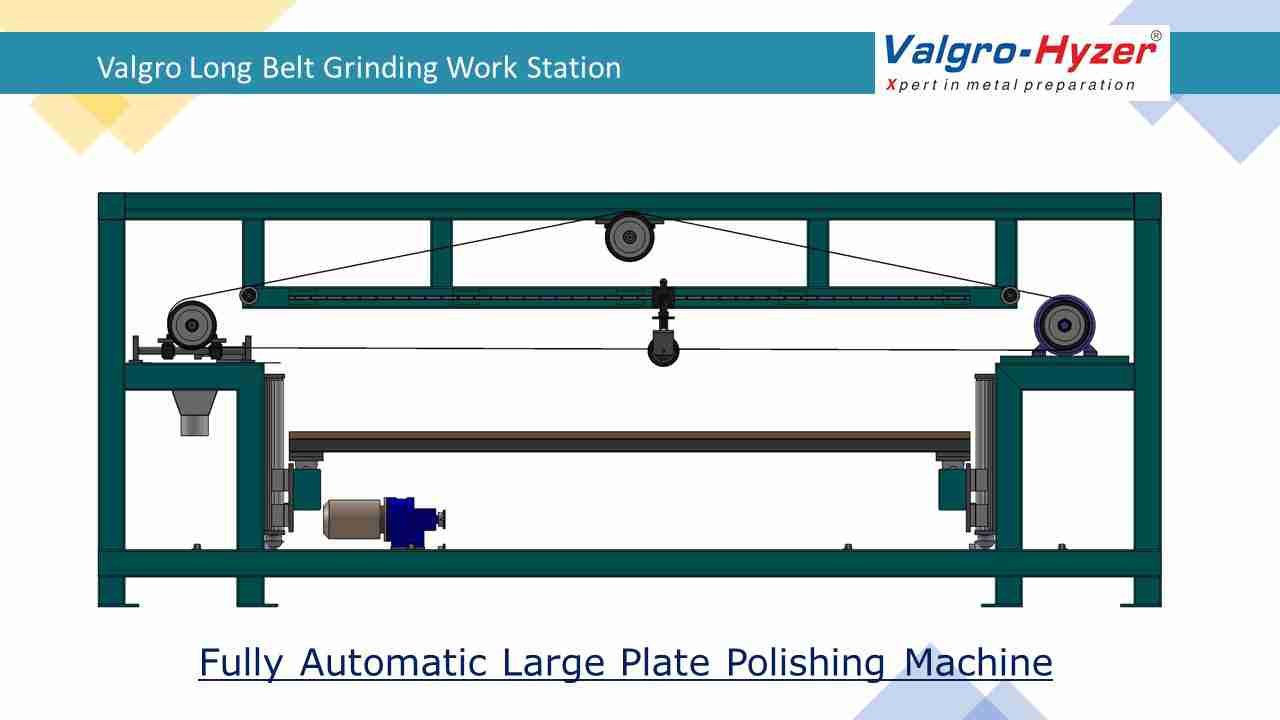

- One grinding belts Station for roughing and finishing

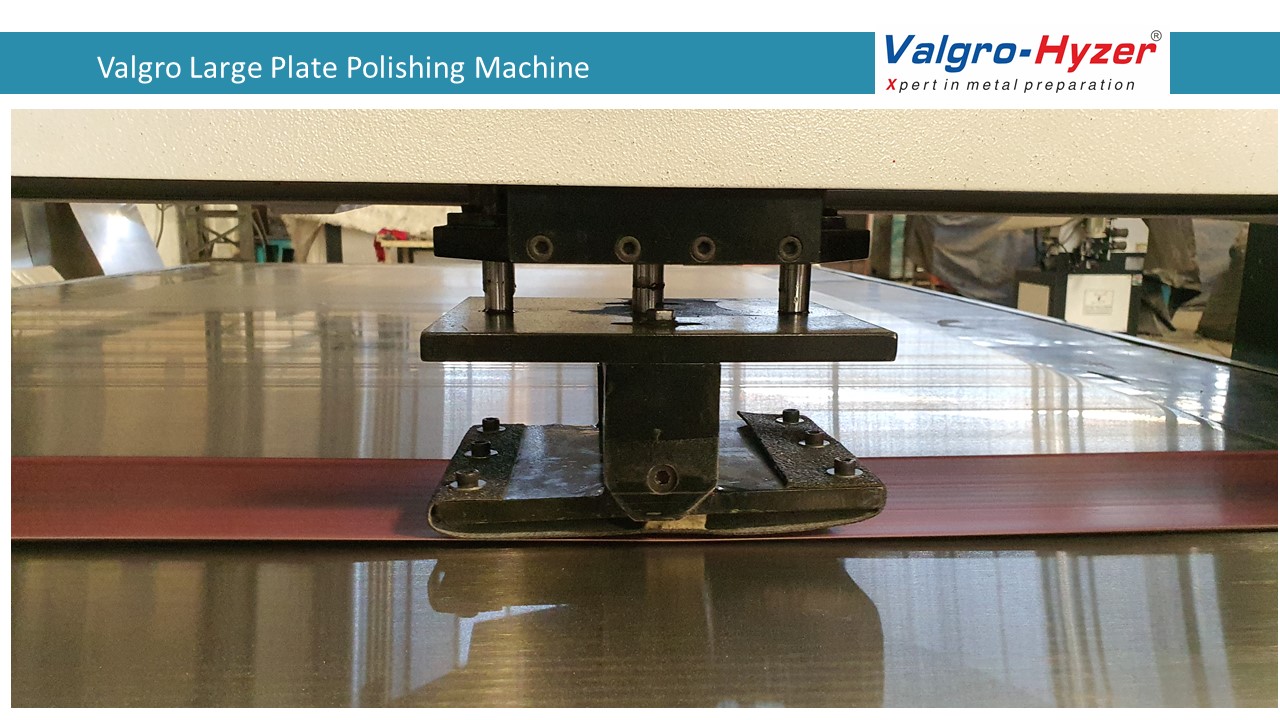

- Triangular configuration for excellent access to and visibility of the working area Pneumatic belt tensioning on durable ball guides Adjustable grinding belt velocity

- Swivel grinding belts up to 90° with perfect

- Belt centering Self centering grinding belt

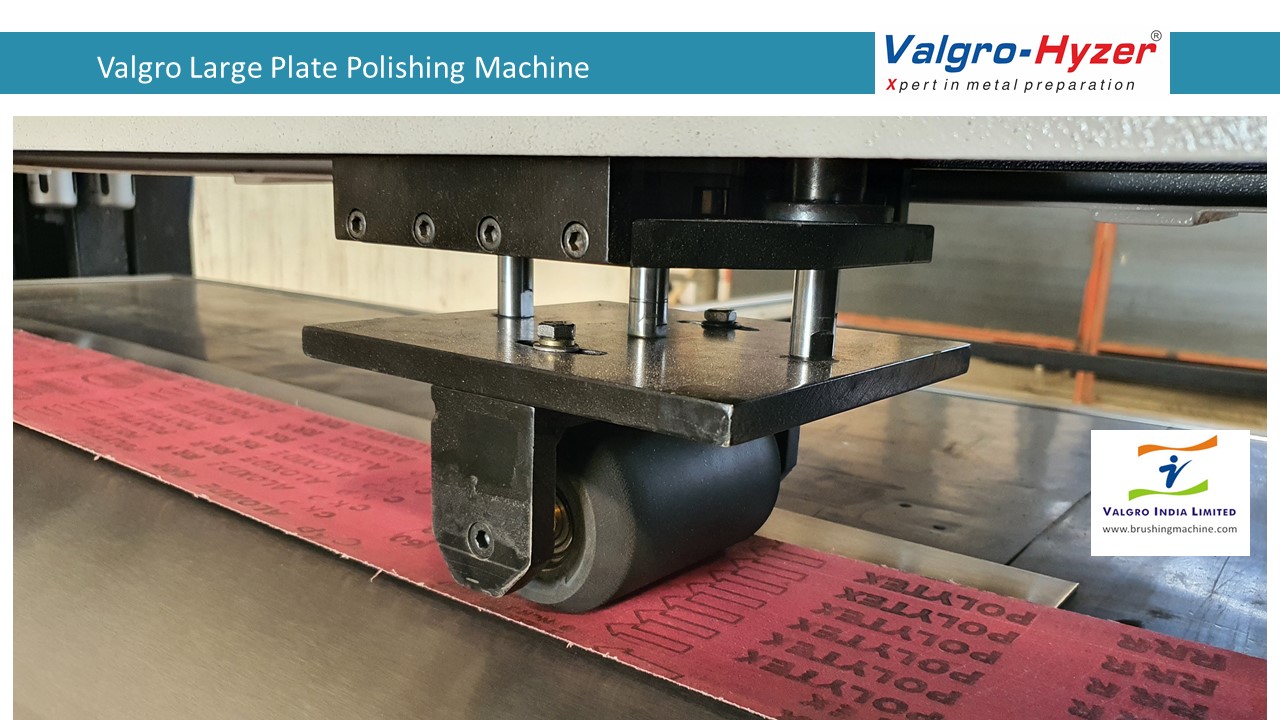

- Pneumatic actuators on belt covers·Smooth moving high capacity prism rollers for table and contact pressure piece movement as well as table height adjustment

Enhanced safety:

- Sliding grinding belt cover

- Safety string

- Belt tension sensor

- Safety switches on doors and covers Free swiveling pressure shoe Pressure roller as an option

Technical Specification

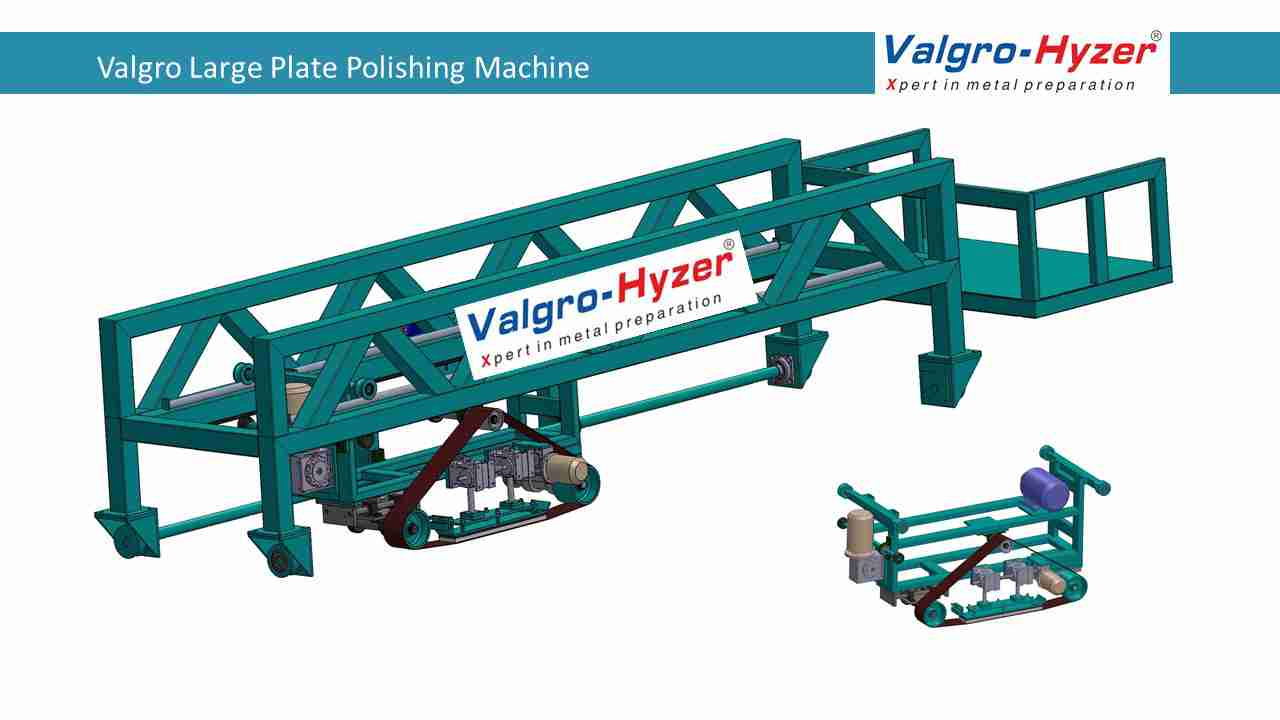

Our newly built and custom designed large plate polishing machine not only increased our ability to process larger and heavier plates, tubes and sheets, but with faster throughput at a lower cost. Please request a quote to see how we can provide you with best-in-class service and platinum results on your next project.

The following applications include examples of our expertise in mirror polishing to a #7 or #8 in stainless steel. Providing parts to a certified RA finish has been key in meeting many of our customers’ needs.

- Food Processing

- Metal Warehouses & Distributors

- Cheese & Dairy Processing Equipment

- High Speed Bottling Machinery

- Hoppers & Tanks

- Custom Built Counters, Tables, Shelving and Displays

- Restaurants (Both Fine Dining & Fast Food)

- Pharmaceutical Production