Help to reduce sound absorption

Ready-for-painting

Ready-for-covering

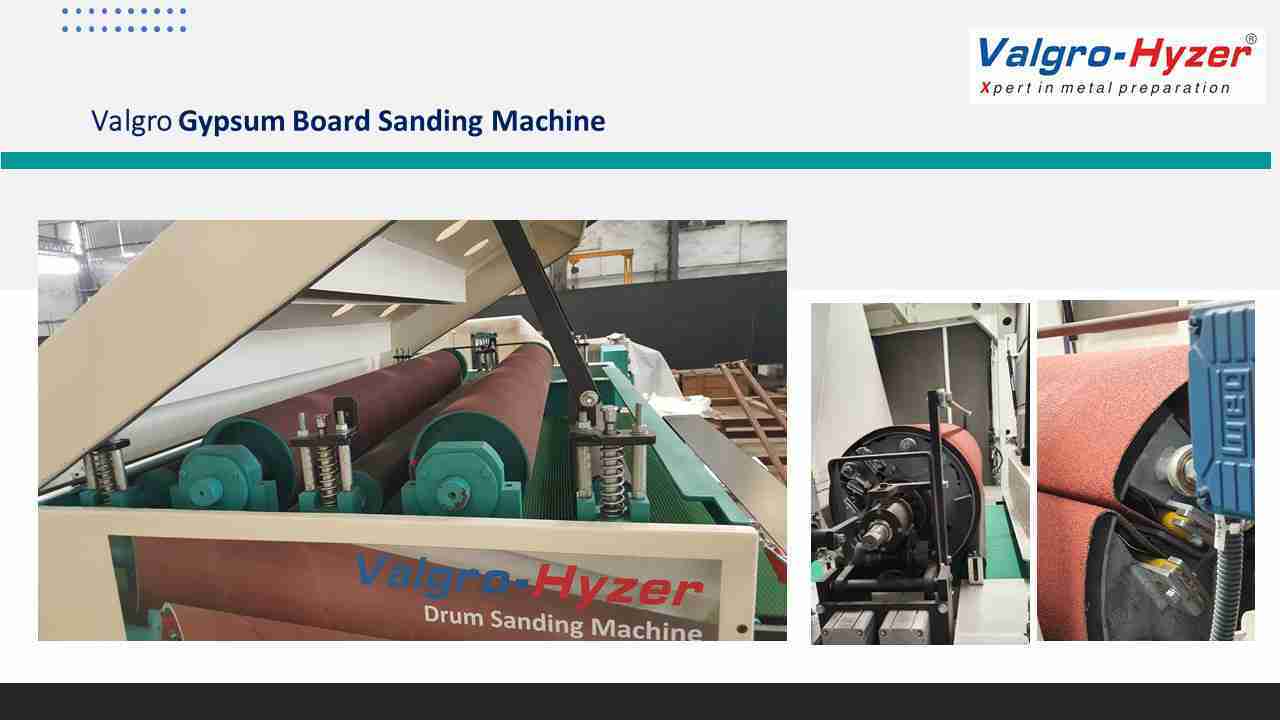

Technical features:

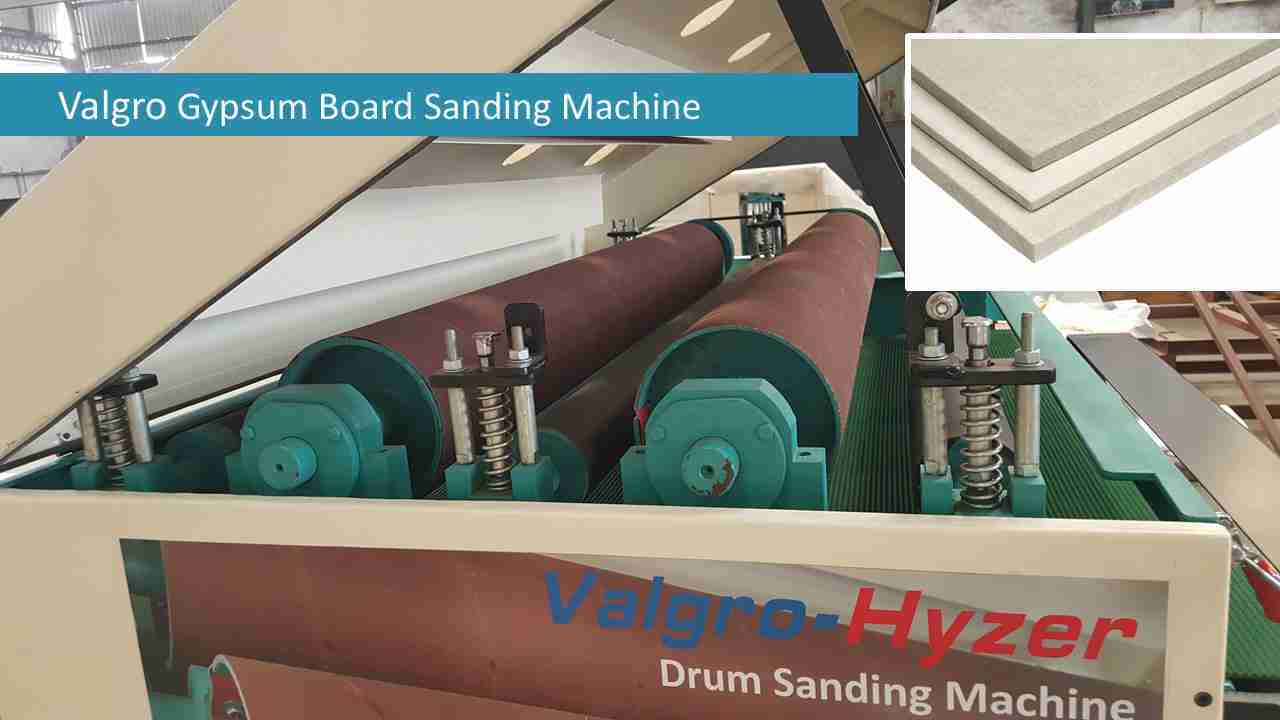

- Two drumhead sender – first head is for rough & second head is for finish.

- Drum Steel roller head dia. 130mm made from Harden steel alloy metal with abrasive resistant rubber coating grind surface.

- Drum Sanding Head speed 960 Rpm

- Adjustable Belt Conveyor Speed from 0.5mpm to 10 mpm

- Maximum Working width 1250mm

- Maximum Working length : 2500mm (2.3mtr)

- Maximum Working thickness : up to 100mm.

Benefits:

- Soft, bright, and homogeneous Sanding surface appearance.

- help to reduce sound absorption

- Ready-for-painting”, “ready-for-covering”

Technical Specification

Custom Design Machine

Drywall finishing requires a good deal of craftsmanship, which is why the gypsum wallboard industry and drywall professionals have codified a set of professional standards that breaks the process of finishing drywall into five distinct levels. Serious do-it-yourselfers should take note of finishing levels if they want their finish to look as professional as possible.

Traditionally, the quality of a surface has been judged subjectively, with the use of phrases such as “ready-for-painting”, “ready-for-covering” and so on. However, these are not suitable for describing the level of finish. A “finished” and “ready-for-painting” surface for one person may be a sub-standard one for another.

The quality of finish of gypsum board is defined by the Euro Gypsum standards (based on EN 13963). The level of finish is affected by the dimensional tolerances of boards, metal framings and level of workmanship. The flatness of the Drywall and Ceiling also impact the level of finish.