With a wide range of conformability options and high consistency, long-lasting Valgro PolyBond wheel are a great option for robotic micro burr removal and Fine Polishing.

Features:

- Finishing applications on eyewear frames and clothing details where ferrous materials like alpaca and titanium alloys are used.

- Finishing on precious metals.

- Lapping and polishing of special cylinders.

- Cleaning and polishing of turbine blades.

- Finishing on precision engineered parts.

- Polishing and finishing surgical instruments.

- Finishing on medical prostheses parts.

- Polishing ski edges.

- Finishing chromium parts.

- Finishing threaded spindles.

- Polishing and finishing circular saw blades and band-saw blades.

- Other applications where minimum abrasion is required for a direct finishing.

Benefits :

- Solid, dense, and conformable wheel produces a professional finish the first time, without undercutting, gouging, or distorting the workpiece

- Effective for all types of metals, composites, and glass, allowing one wheel to perform more tasks

- Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing

- Convolute construction keeps the wheel running smooth, producing a consistent, superior finish

- Minimizes heat build up to reduce risk of discoloration and warping on heat-sensitive substrates

- Minimizes heat build up to reduce risk of discoloration and warping on heat-sensitive substrates

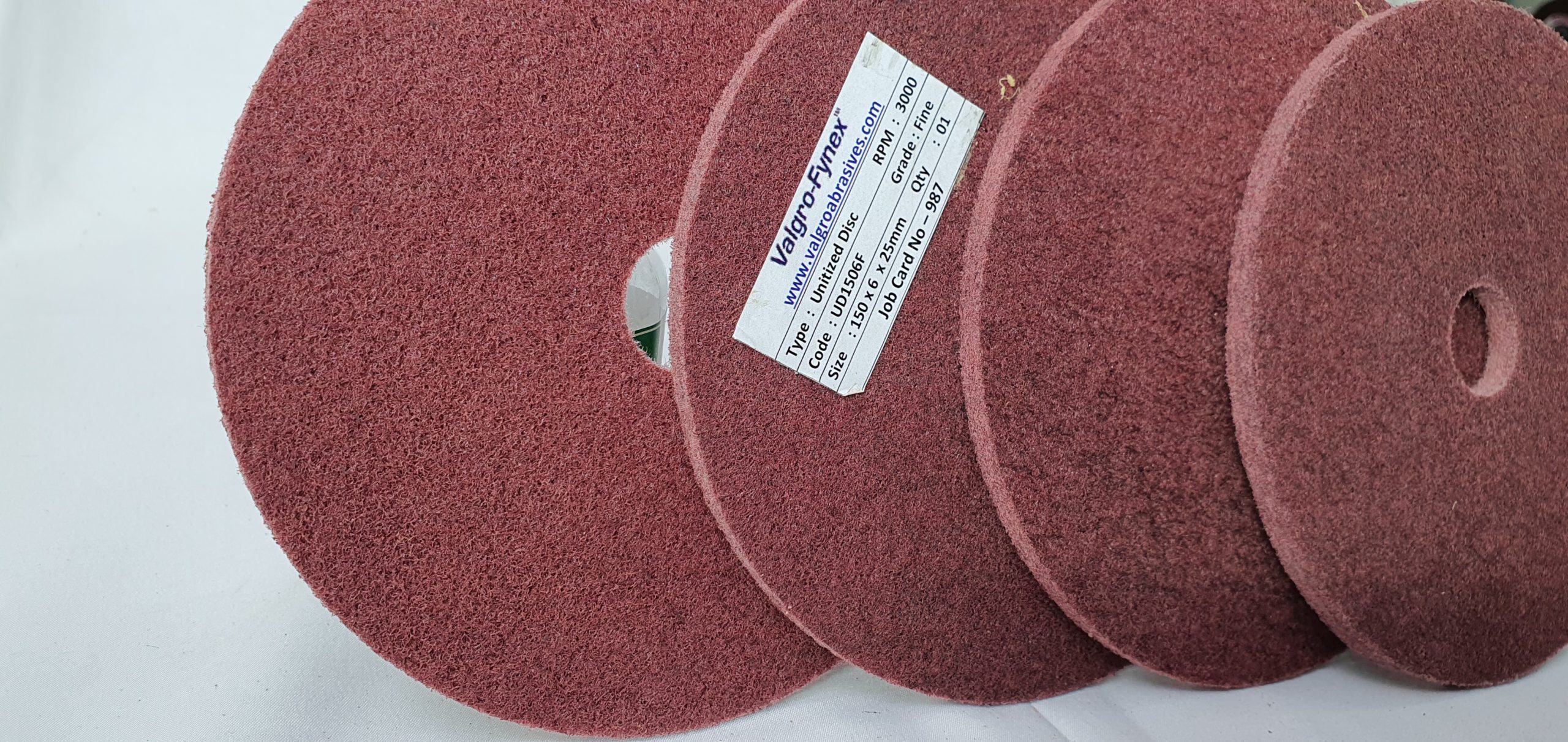

Technical Specification

Wheel outer dia 25mm – 350mm Wheel Width 6mm to 300mm Grade : Coarse, Medium, fine, Ultrafine Construction : Convolute / Compress Disc Deburring

Aerospace component manufacturers: Blades, Vanes, Rotors, Housings, Fasteners, Airframe Parts, Extrusion, Control Surface, Rocket Cans, Nozzles, Valves, Etc.

Other Manufacturers : A Hand tools, Builder and Furniture hardware, Machinery Instrument, Surgical Instrument, Engines and Components, Formed wire products, Aluminum extruders, Automobiles Equipment,