Wood Working Industries

Application: Removing excess filler, de-fuzzing rubbing down primer, Light sanding, Sealer sanding...

Weld Shops

Application : Surface preparation for weld area grind, clean weld splatter, etc. Products : Fin...

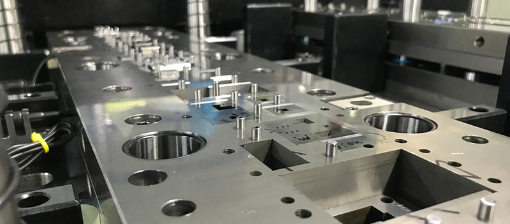

Tool & Die Shops

Application : Deburring polishing molds Products : Finishing Mops wheels, Sanding pad, Unitised...

Ship Building

Better quality is achieved : Valgro products are consistent. This is particularly useful to the mic...

Stamping Plants

Application : Polishing stamping dies, breaking sharp edge. Products : Heavy-duty Deburring whe...

Rubber Plant

Application : Remove excess rubber, deflash and gring whitewall area, Die and mold grinding & F...

Pulp & Paper Mill Industries

Application : Finishing paper roll, Cleanout relief angle on Doctor blades, deburring Master Grindi...

Power Station

Application : Preparing welded surface, stripping rust or paint, clean threads, inside cleaning of...

Pharma Food Industries

Application : Cleaning & Polishing stainless tank, Grind, and polish spot weld, Cleaning S.S. a...

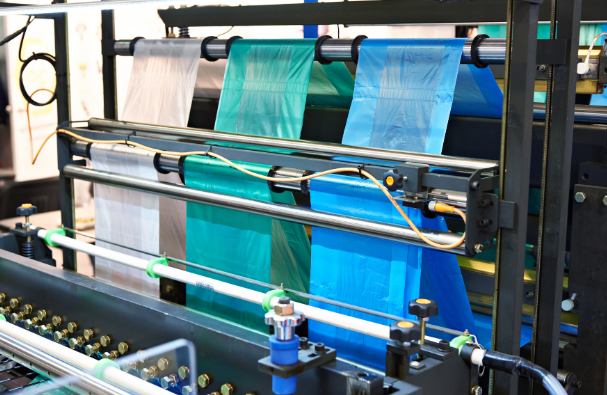

Plastic machinery manufacturers

Application : Polishing of extrusion screws & barrel, injection molding screw and die finishing...

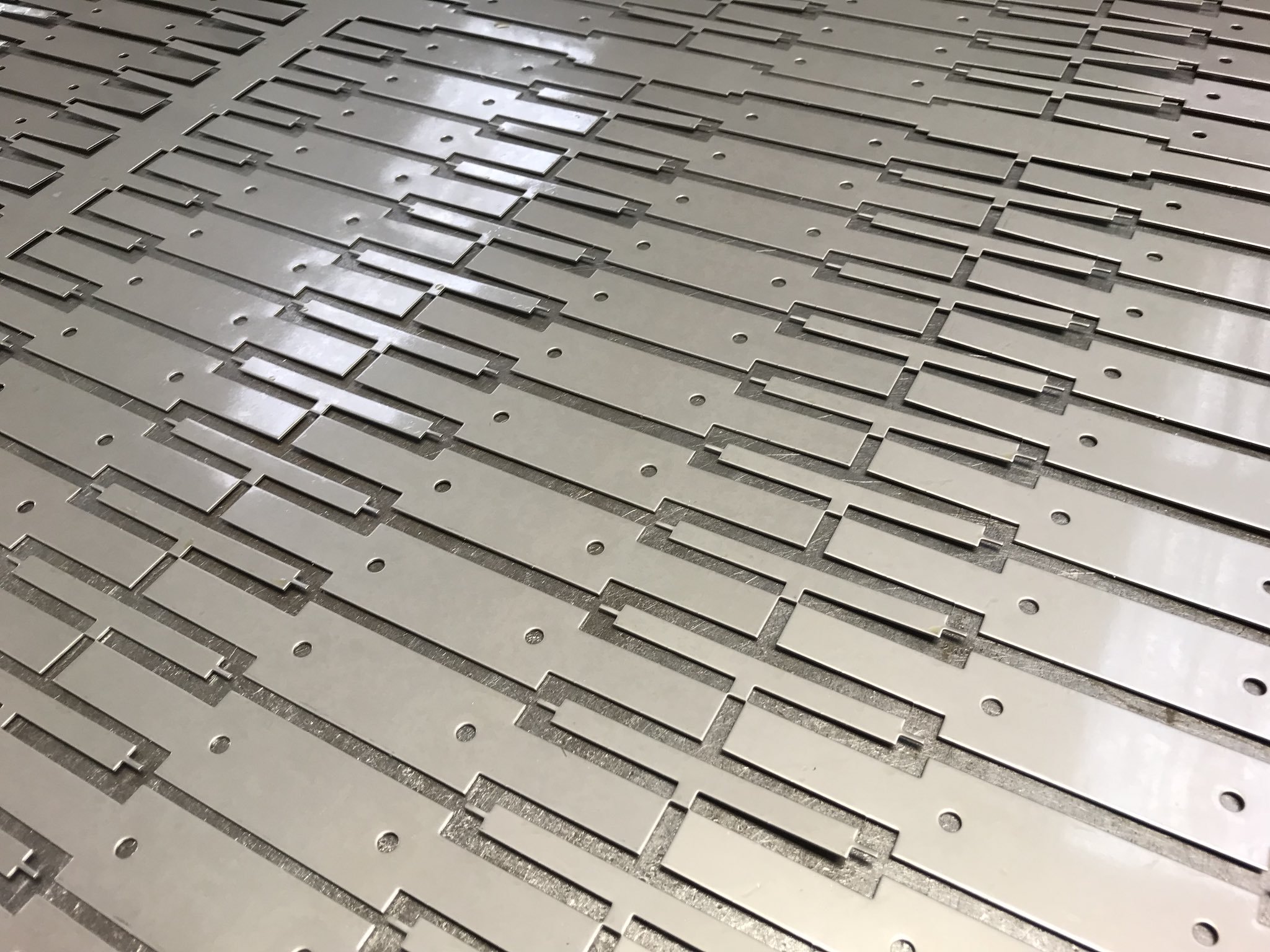

Metal Strip Industries

Performance Highlights : Remove debris & contamination from surfaces, to create a clean su...

Machine shop & Engineering Industry

Application : Deburring and Cleaning machine parts, Gear teeth/thread deburring, Ture edge radius w...

Jet Turbine Blade Manufacturers

Application : Sanding pad / Roll, Polishing Mops, Flaps, Square Buff, Coated flap / Disc, Strip-cut...

Hospital / Pharma machinery Mfg.

Application : Cleaning & Finishing S.S. Trolley, Cabinet, Table, Matt finishing on S.S. Article...

Hollowware Industries

Application : Staining S.S. kettles, Removing routing lines on Aluminium, Sunburst finishing on bra...

Aircraft Manufacturers

Application : Sanding airplane skins, deburring, Polishing of engine parts, Scratch mark removal, d...

Auto Aftermarket

Application : Paint removal and surface preparation, Putty sanding, dust nub removal, “Feathe...

Auto-Bus Body Builders

Application : Dust nib removal, roof seam weld grinding, door jamb grinding, scuff sanding, surface...

Chemical Plant

Application : Removing Gasket material, Light & Heavy oxidation removal, grind welds, deburring...

Drug & Pharma Industries

Application : Cleaning & Polishing stainless tank, Grind, and polish spot weld, Cleaning S.S. a...

Electronic Industries

Application : PCB Deburring, Cleaning light oxidation rust, Cleaning prior to electro-less copper p...

Roughening

This applies particularly to thin cold-rolled products, (sheet and coil), and may adversely aff...

Vibration Finish

Vibration Finish sheets are one of the most commonly used finish in stainless steel sheets and plate...

Non-Directional Orbital Finish

Non-directional finish also known as random-orbit finish or Vibration Finish, very popular among arc...

Straight Line Grain Finish

A most common finish for stainless steel sheet metal parts with various abrasives belt grinding or b...

Surface Finish

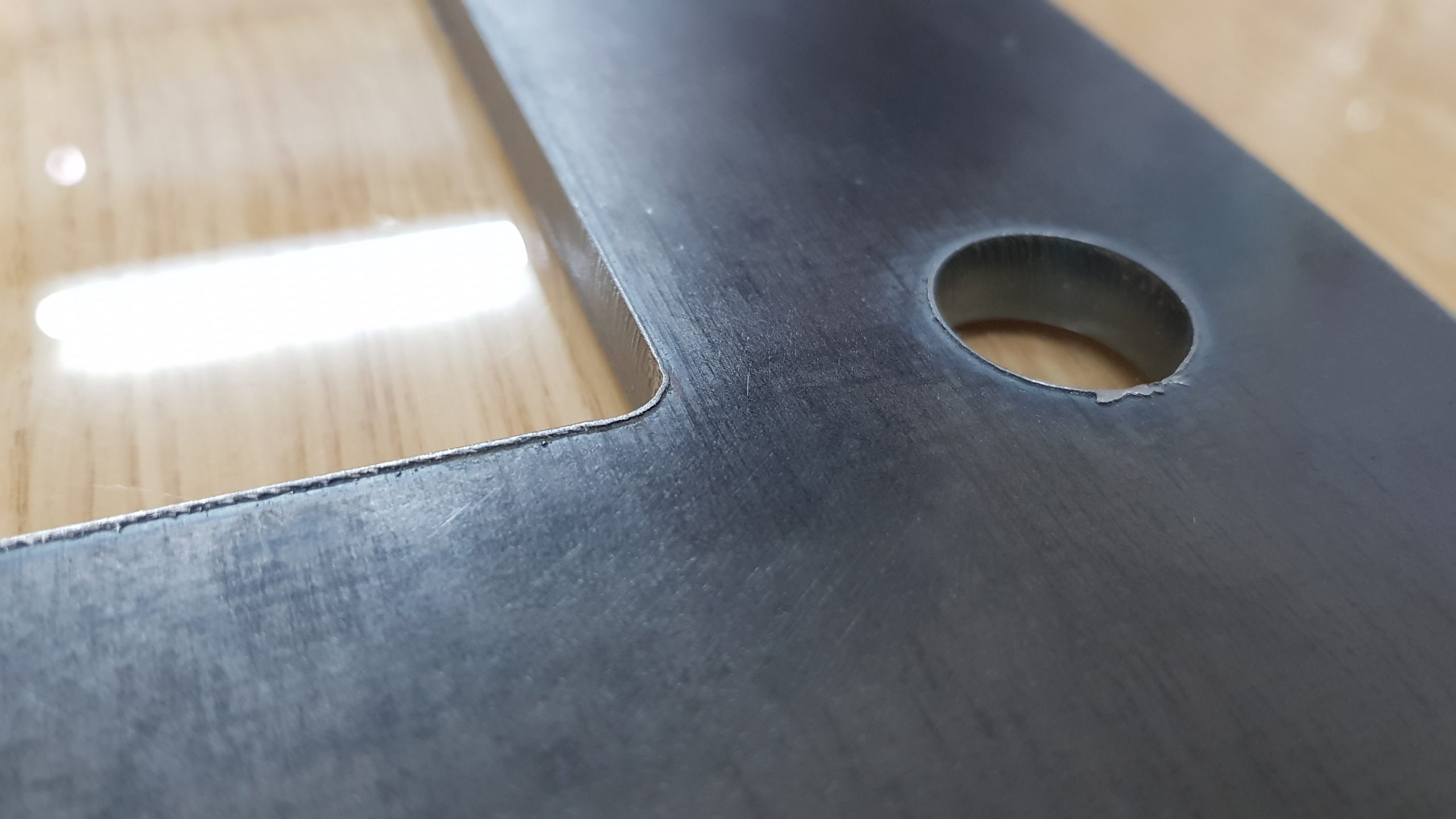

Punched and laser-cut parts often require high demands on the surface. A beautiful surface is a plea...

Micro Joint Removal

The traditional micro-joint method places small, interconnecting tabs between parts by programming s...

De-slagging / Slag Removal

The slag on oxyfuel or plasma-cut parts has to be removed via hand grinding before the actual deburr...

Oxide Removal

If you are cutting via a CO2 -laser with oxygen, the Classic Hybrid can remove any oxide layers alon...

DRESSING PLATE – WIDE FACE ABRASIVE NON-WOVEN BRUSH

Care and feeding of Non-woven Brushes. Because of the tendency of non-woven nylon brushes to wear...

Why Valgro is most preferred Emerging brand in Metal Finishing ?

Pricing – Committed to providing a competitive price and, the service to match individ...

Understanding the Differences between Deburring and Finishing

Deburring involves removing any raised edges or small pieces of material that remain attache...

Burr Classification – Definition & Valgro Solution

Class #1 Micro Burr : Definition : Micro burrs can only be observed using magn...

Why Valgro Success in Metal Surface preparation?

To make machines and to bring desired results, both are different things. Our expertise in surface c...

11 Way of Deburring Process in Sheet Metal Processing

Deburring is important for Safety & Quality, Aesthetics, Functionality, and the smooth operation...

New Series 2021affordable Deburring and Metal Finishing

During the Corona pandemic, we develop various deburring solutions for sheet metal Processing full line of deburring and metal finishing machines with all international standards: We develop 14 Awesome deburring machines for sheet metal processing.

Making brushing and polishing operations smooth

BRUSHING, polishing, cleaning, and surface preparation are common operations in metalworking industries to meet industrial and household needs, but having effective and desired solutions in this regard is something that eludes many companies.

Food & Dairy Industries / Equip Mfg.

Cleaning & Polishing stainless tank, Grind, and polish spot weld, Cleaning S.S. assembly line, countertops, trays, Cleaning of S.S. Plants and machinery, etc.

Edge rounding

A good quality Edge rounding outcome is to identify by removing the sharpness on the Edges of your l...