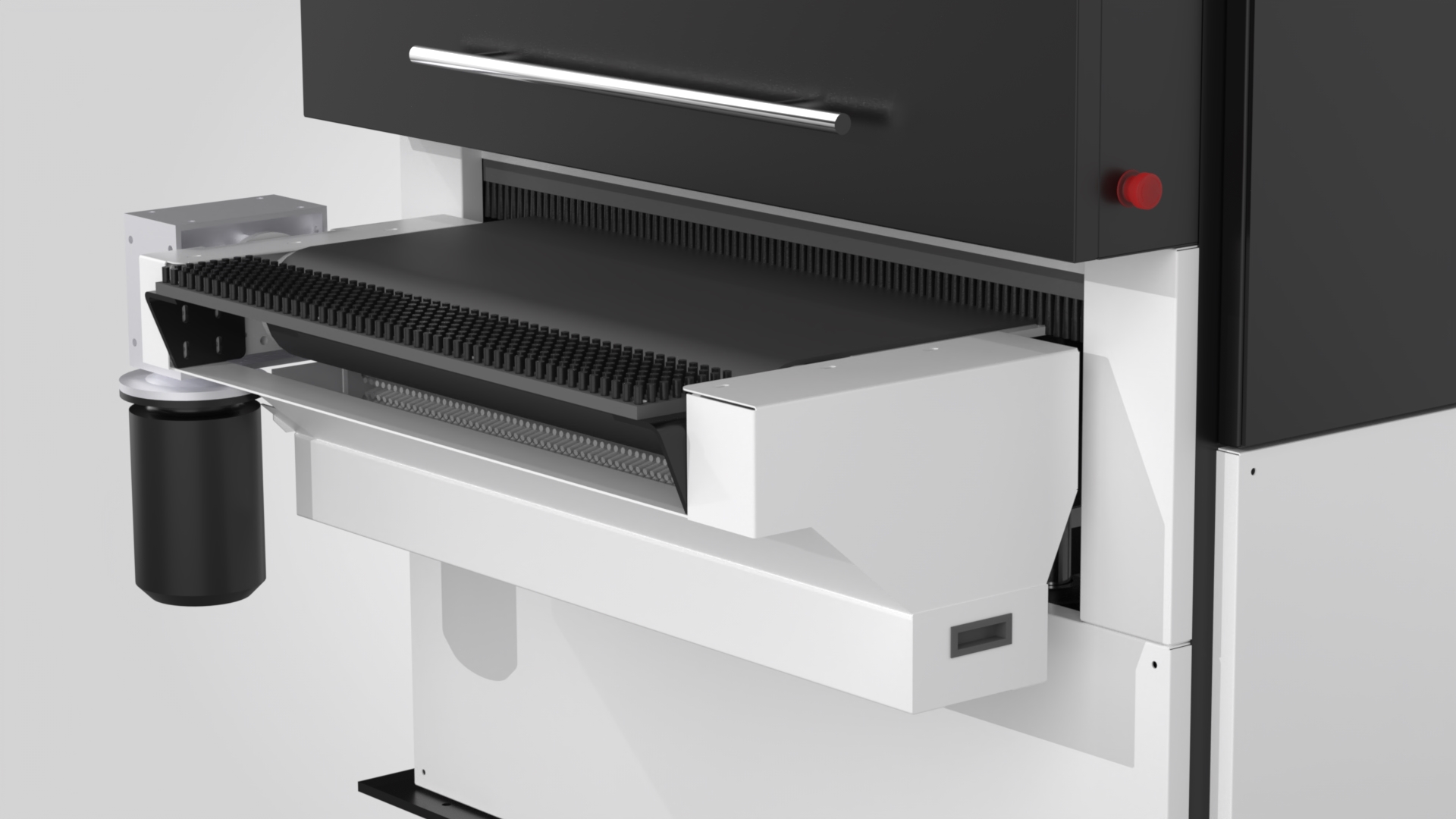

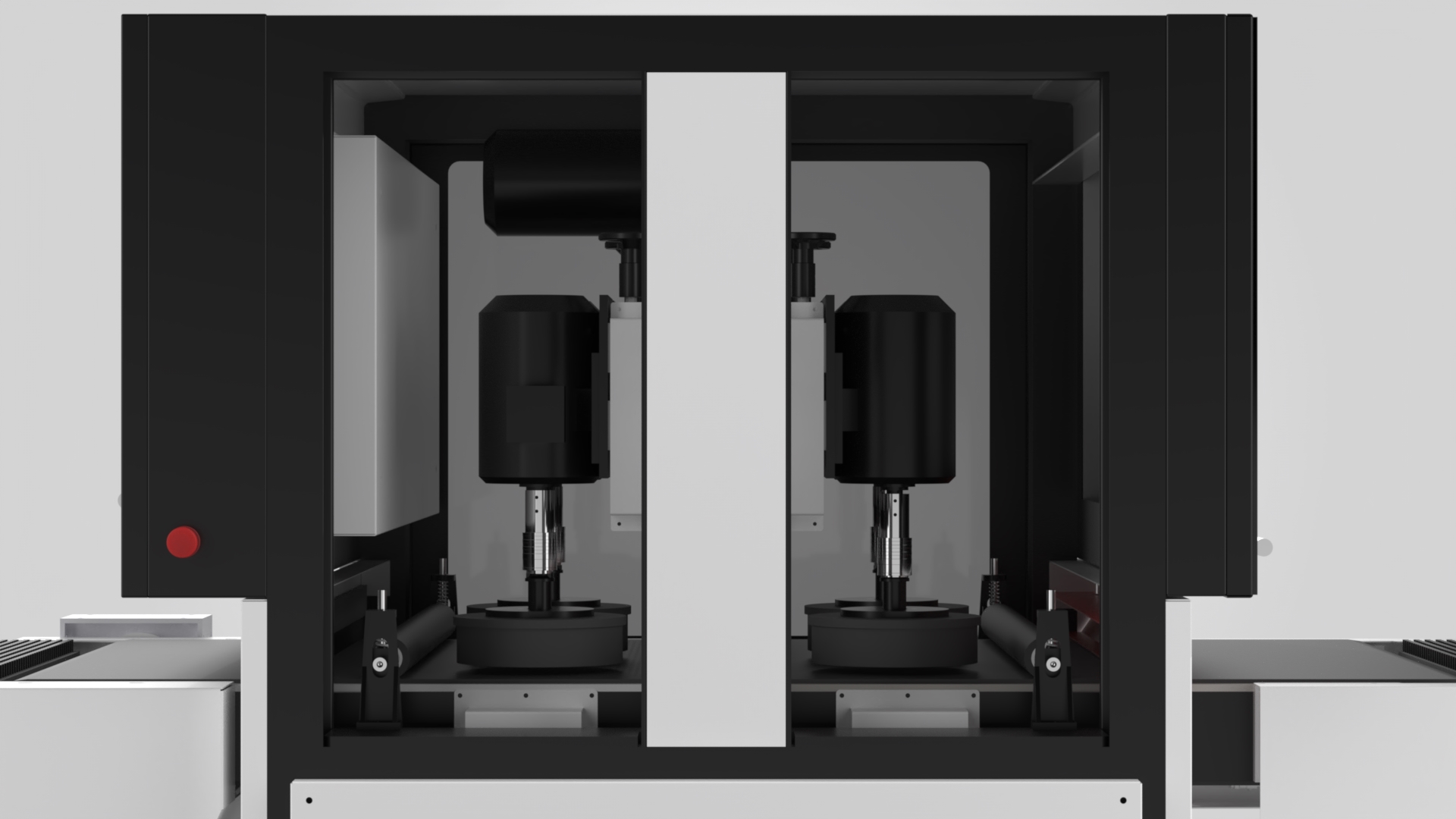

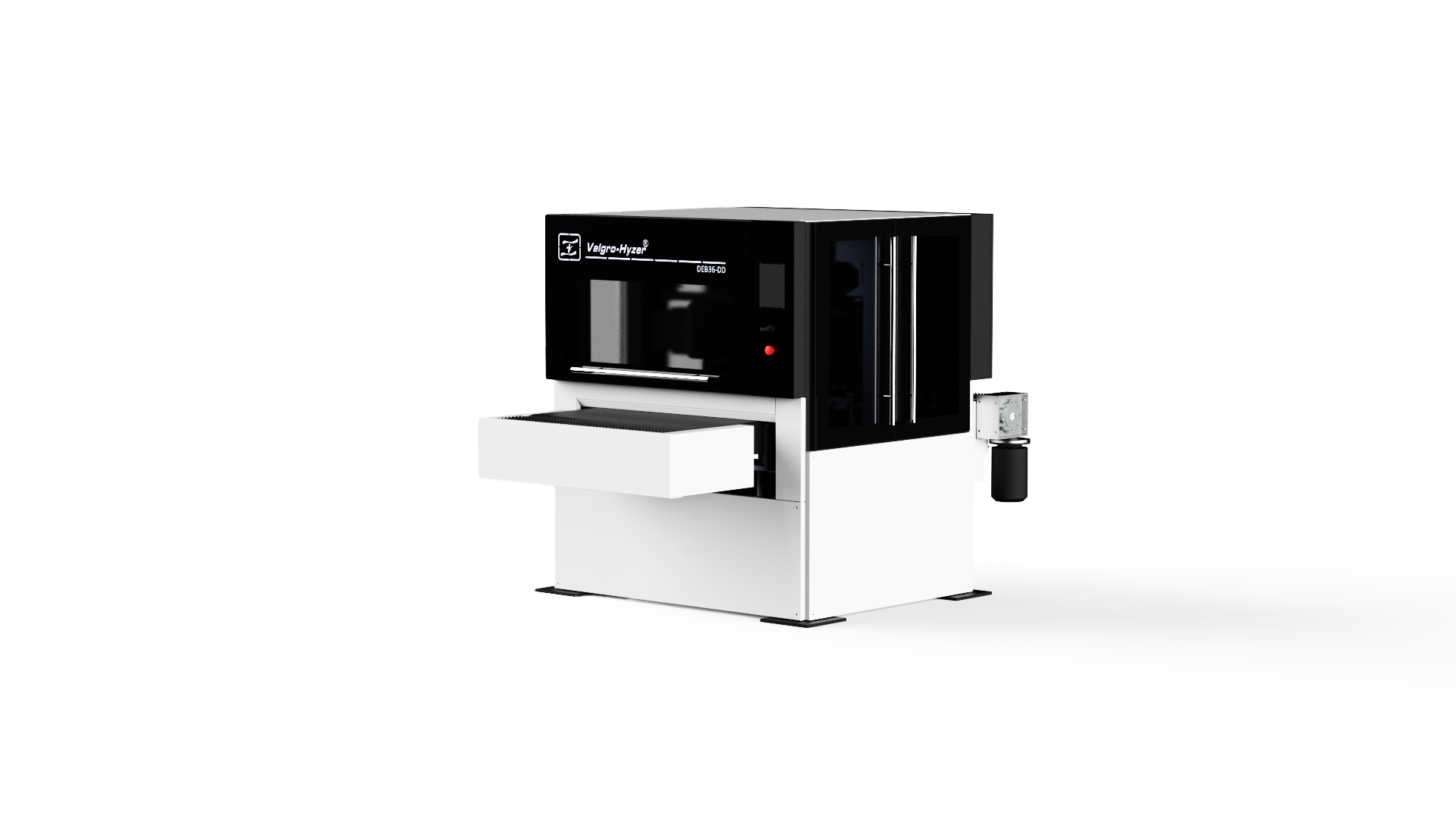

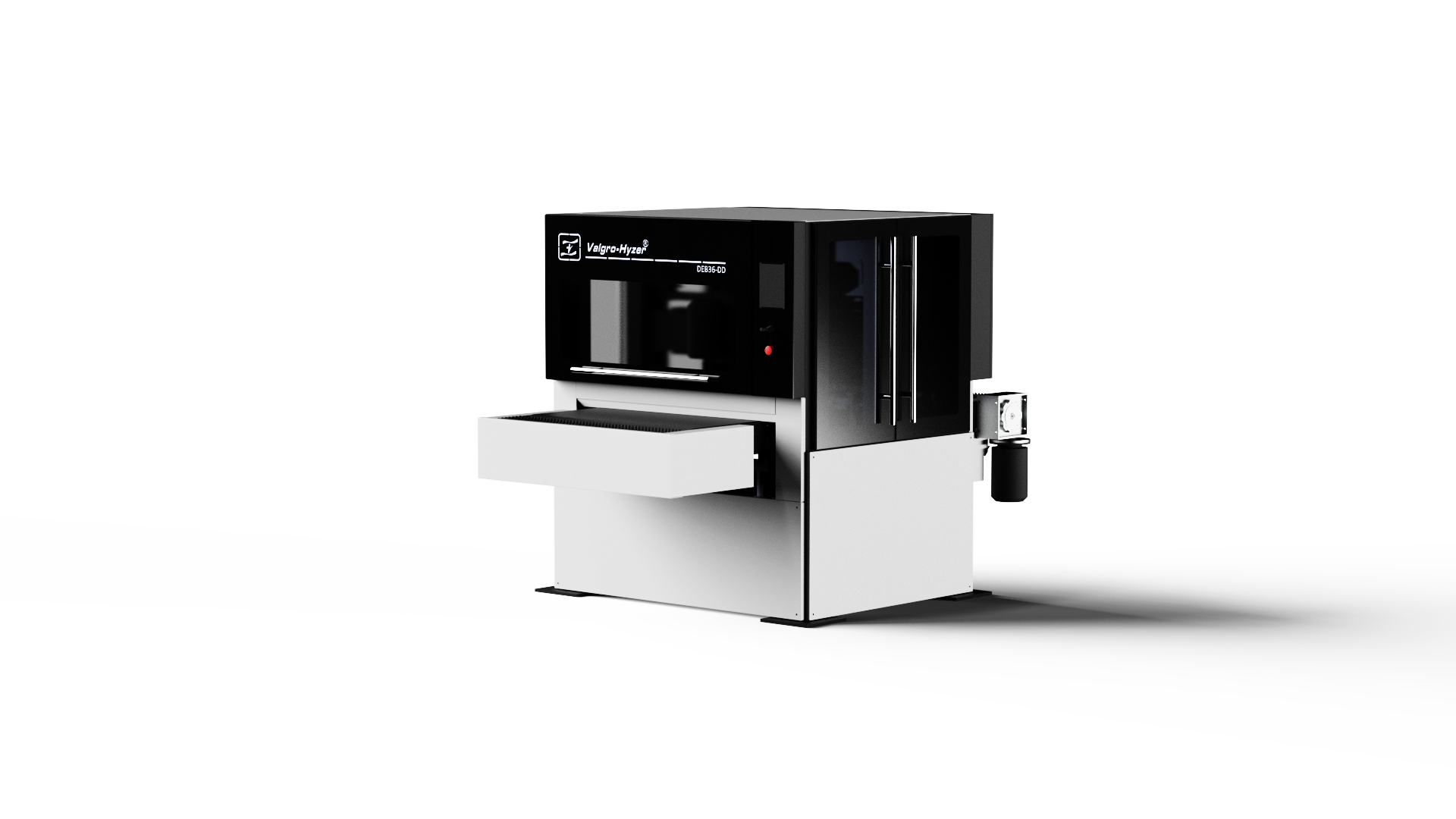

The Valgro Samarth Edge Breaker Series is a through-feed precision deburring and edge rounding machine engineered to deliver consistent edge quality on ferrous and non-ferrous sheet metal parts. Its dual-disc action processes the inside and outside edges from multiple angles, ensuring reliable burr removal with consistent results across the full working width.

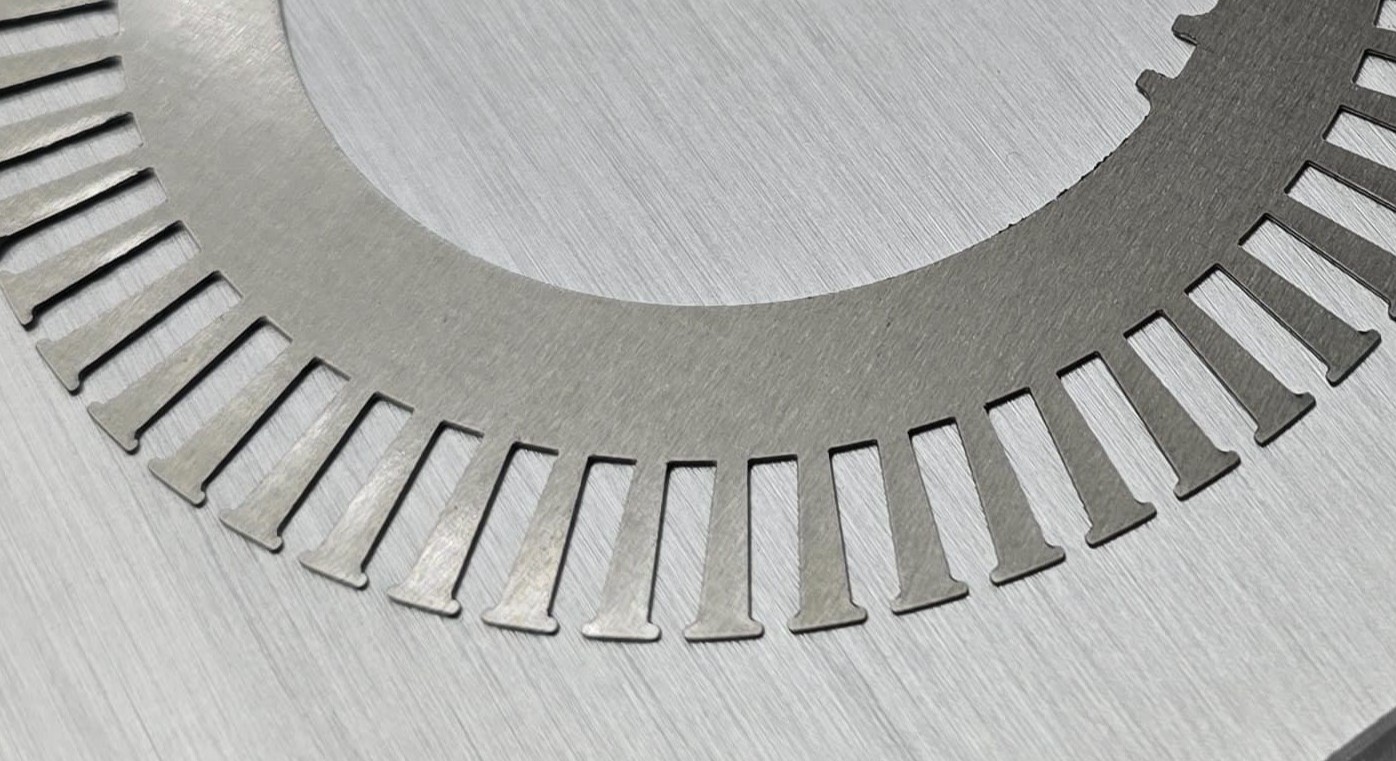

A key USP of the Valgro Edge Breaker Series is its ability to process fine-blanked parts and plastic-coated sheets while preserving surface quality and the protective plastic layer. The deburring action remains focused on edge burrs only, avoiding surface scratches, coating damage, or film peeling—making it ideal for sensitive, surface-critical components.

In addition to edge finishing, the series can deliver a uniform brush roughening effect that improves powder coating adhesion and supports a flawless final finish. Designed for high productivity, it significantly reduces or eliminates manual deburring, saving time and effort while delivering precise, repeatable results shift after shift.

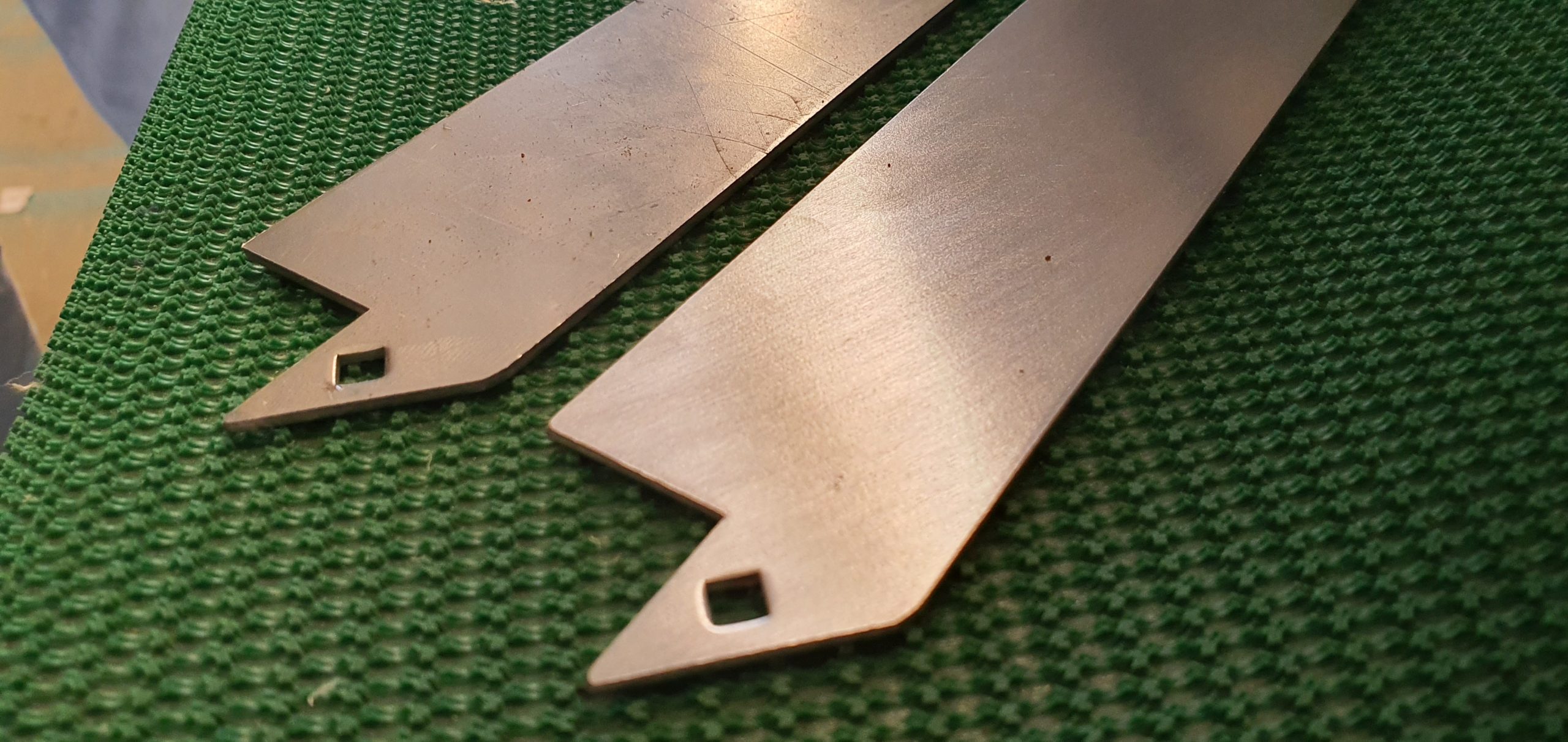

- Precise Edge Deburring (Fine-Blanking Safe): Removes edge burrs effectively on fine-blanked parts without disturbing the surface—helping prevent deformation, scratches, or surface marks on delicate components.

- Coating-Safe Processing for Plastic-Coated Sheets: Deburrs edges while keeping the protective plastic layer intact—no peeling, tearing, or surface damage to coated/laminated sheets.

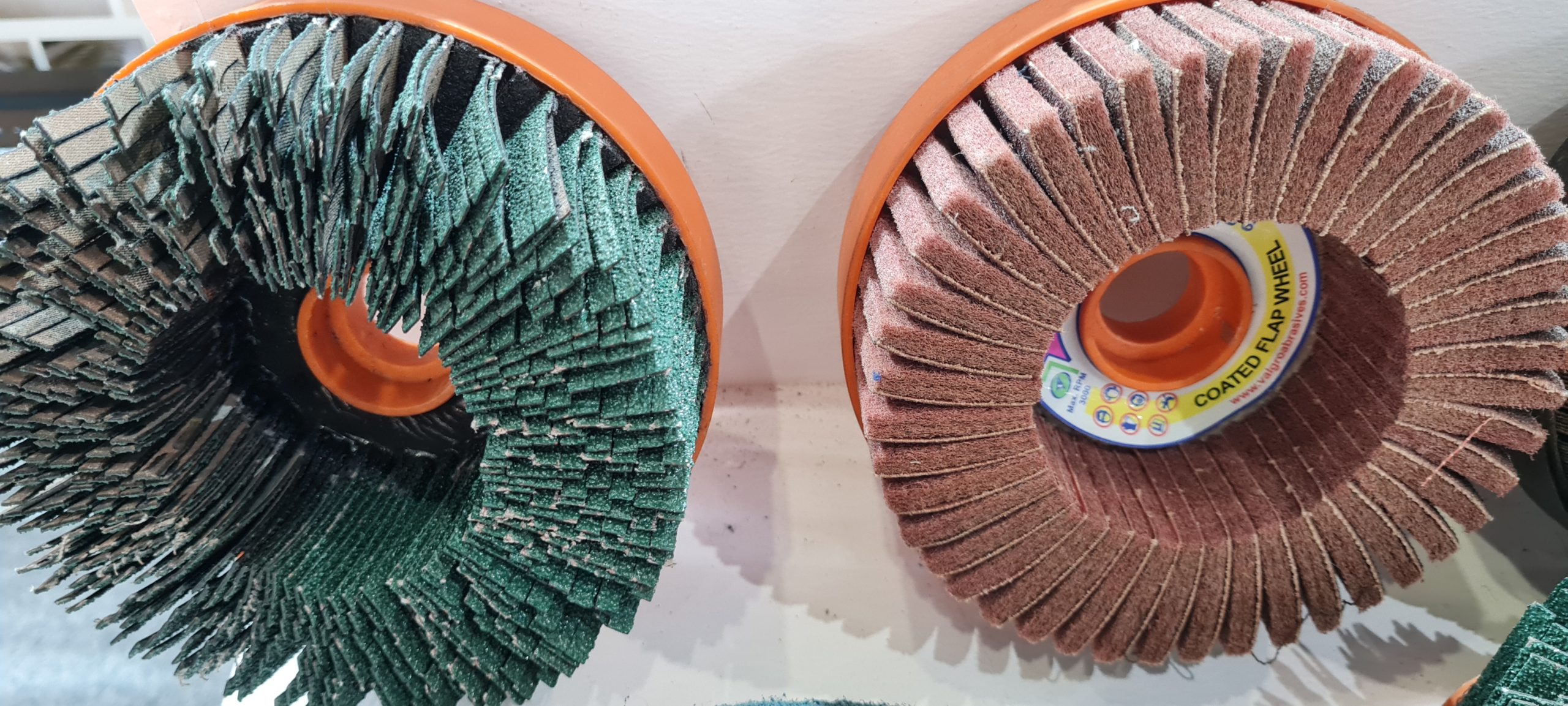

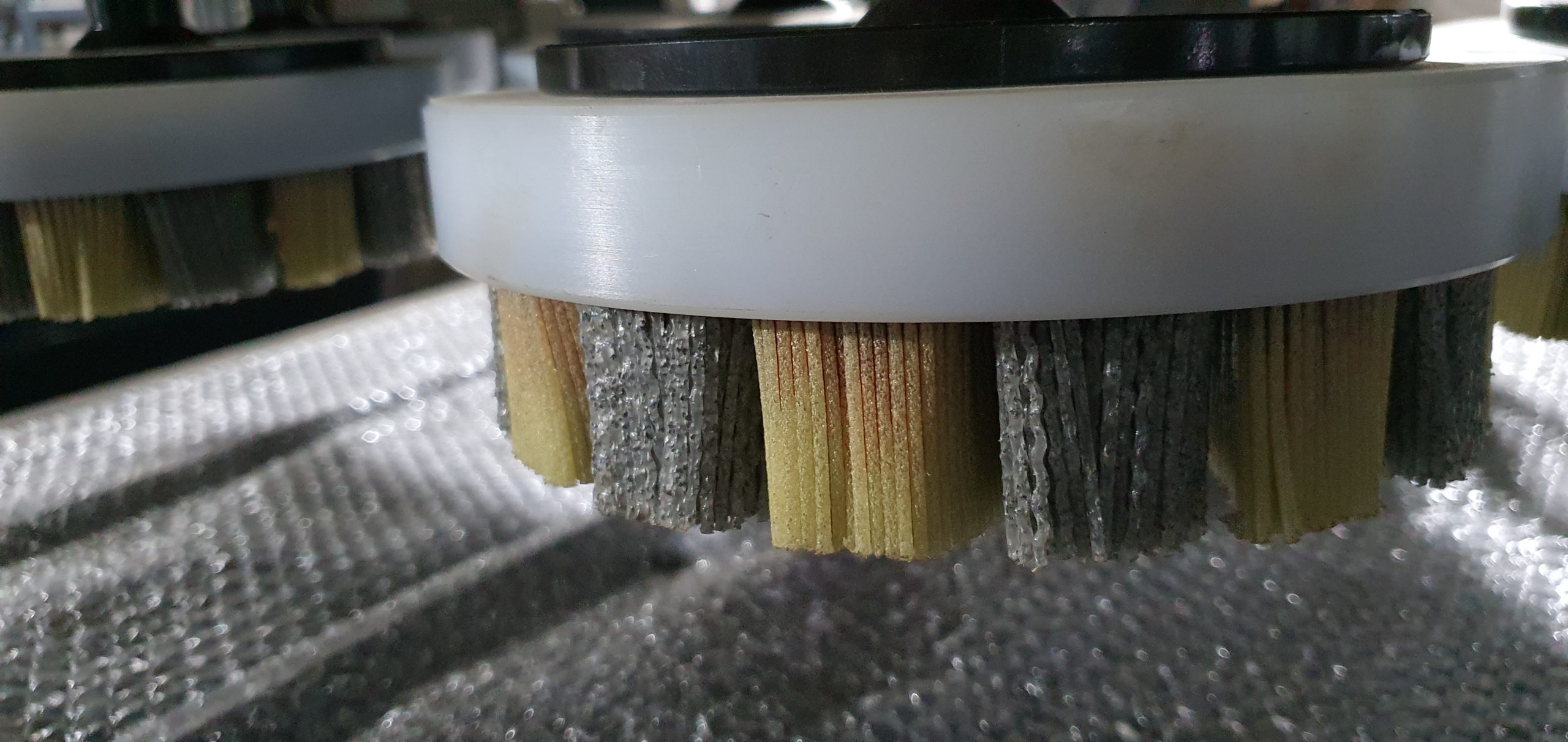

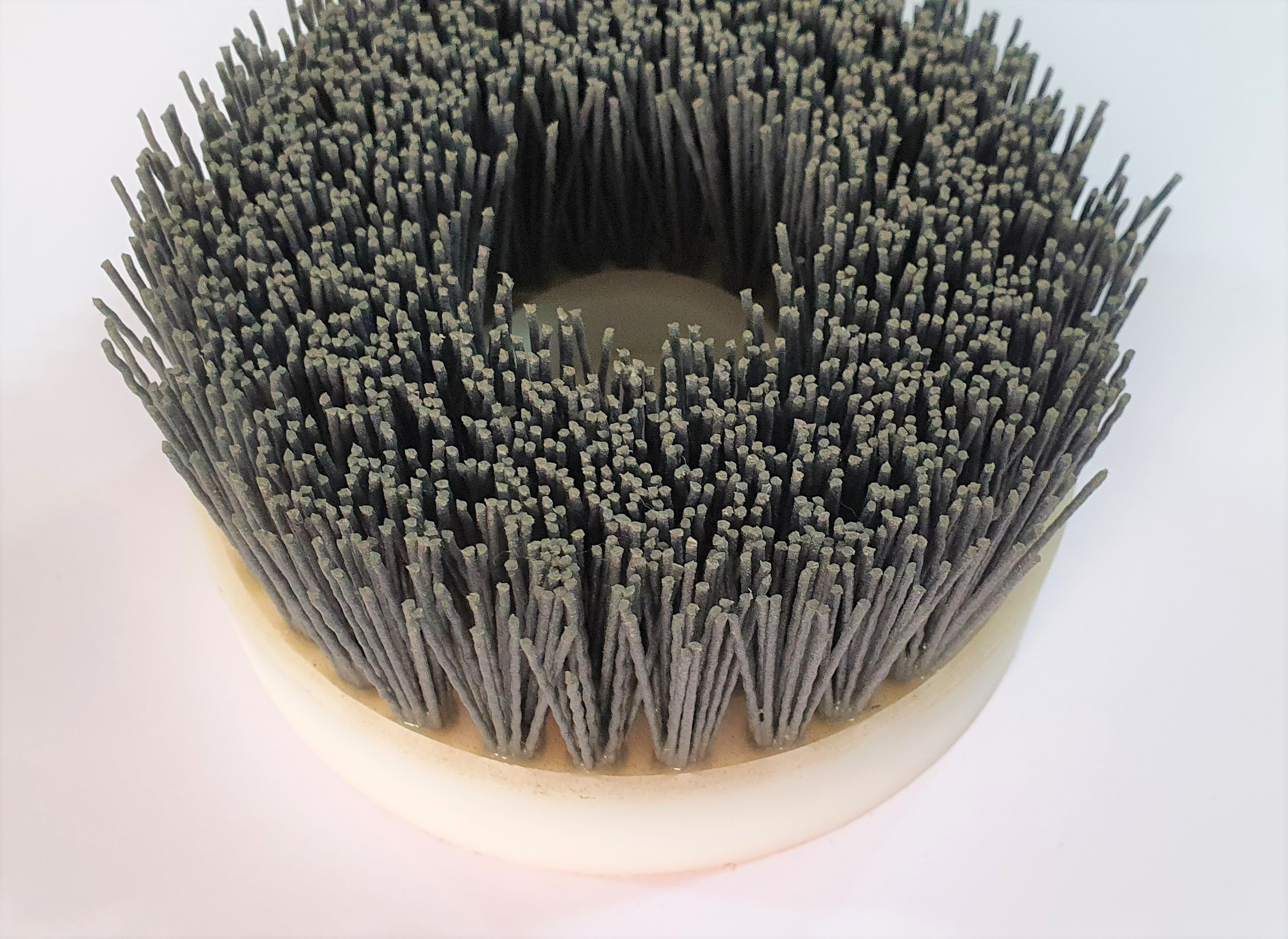

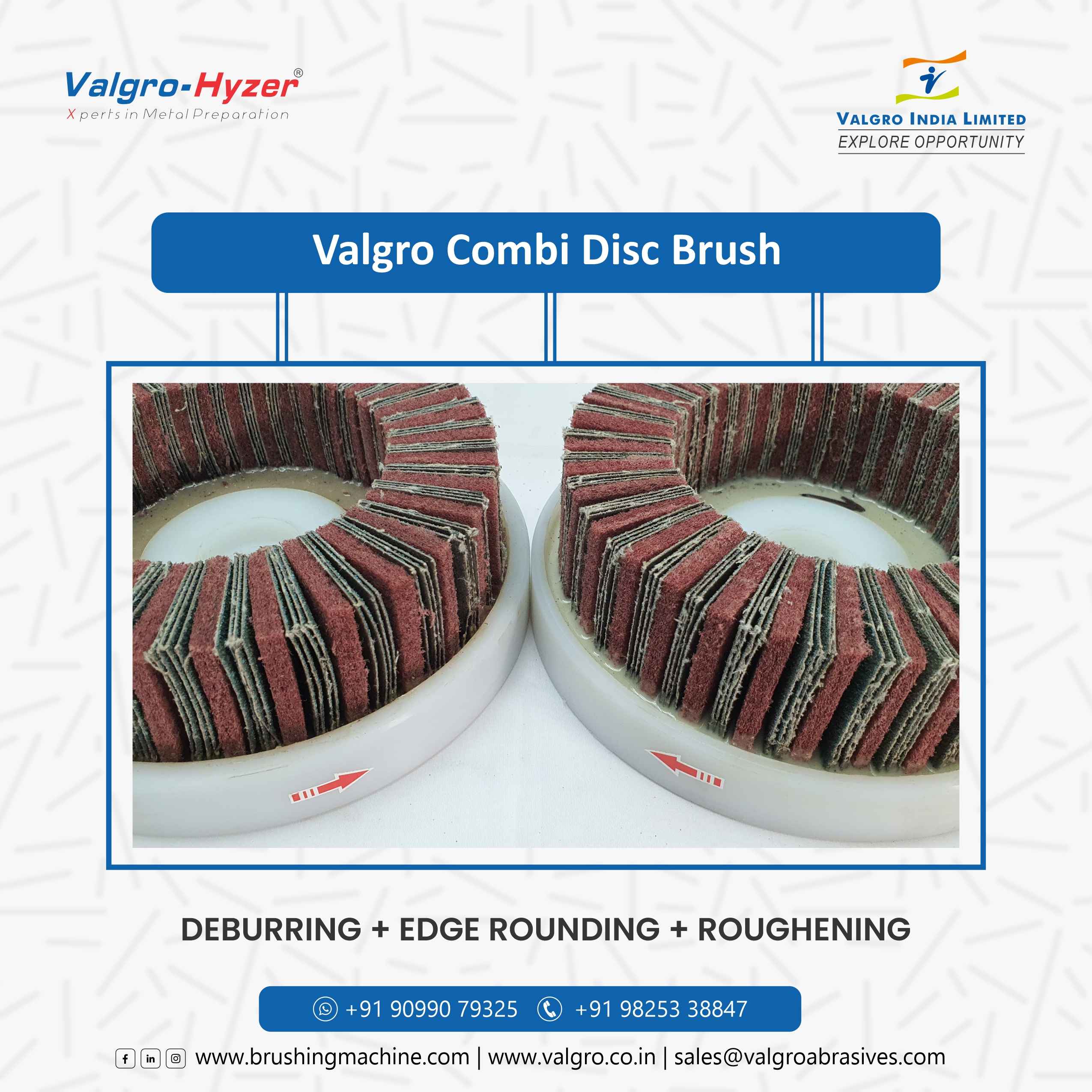

- Roller + Disc Brush Technology: High-performance roller and disc brush combination delivers uniform burr removal and controlled edge conditioning, ideal for surface-critical parts.

- Adjustable Brush Pressure Control: Fine-tune brush pressure to match different materials and burr conditions, ensuring consistent results with process flexibility.

- Dual-Process Versatility: One platform for both metal parts and plastic-coated sheets—perfect for mixed production and job-shop environments.

- Fully Automated Operation: Automated through-feed processing delivers repeatable output with minimal manual intervention, reducing operator fatigue and improving productivity.

Technical Highlights – Edge-Safe & Coating-Safe Deburring

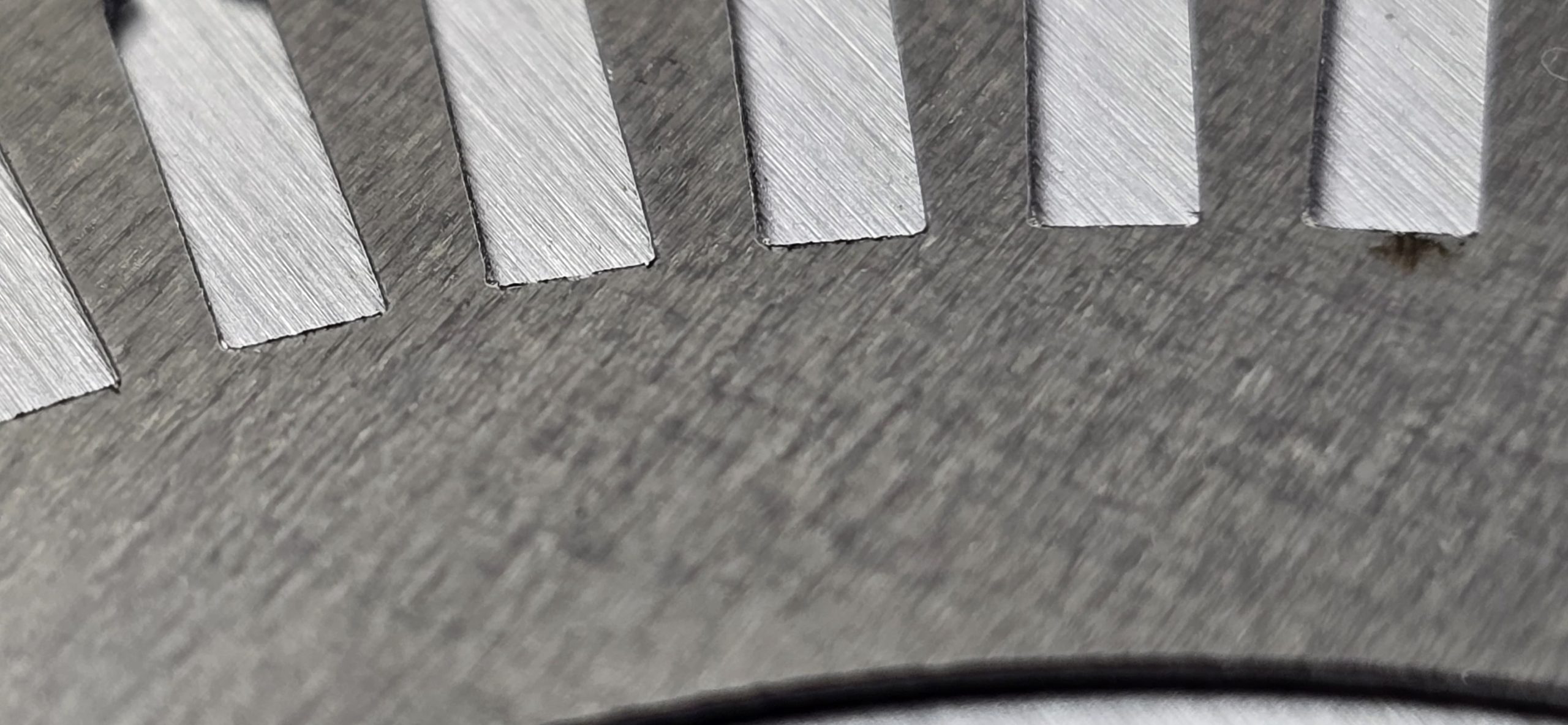

- Edge-Focused Burr Removal: Processing action is concentrated on edge burrs of fine-blanked parts, minimizing surface contact and reducing risk of deformation or surface damage.

- Non-Aggressive on Coated Sheets: Optimized brush interaction supports deburring of plastic-coated/laminated sheets without damaging or peeling the protective layer.

- Roller & Disc Brush Configuration: High-performance roller and disc brushes provide uniform burr removal with controlled finishing, suitable for sensitive and delicate materials.

- Adjustable Brush Pressure: Operator-adjustable pressure enables optimization for material hardness, thickness, burr height, and coating sensitivity.

- Multi-Material Capability: Compatible with metal parts and coated sheets, enabling mixed-material processing on a single machine platform.

- Automated Through-Feed System: Automation ensures consistent, repeatable results with reduced dependency on manual deburring and reduced operator fatigue.

Typical Parts & Processes

- Deburring + edge rounding of laser-cut, plasma-cut, and waterjet-cut parts

- Deburring + edge rounding of fine-blanked parts with surface-safe edge finishing

- Deburring + edge rounding of punched parts and 3D punched / formed components

- Edge rounding + orbital-style finishing in one pass (process-dependent)

- Processing of small parts from 20 mm × 20 mm (with suitable holding / support options)

- Automotive, aerospace, defence, electronics, and machinery components requiring consistent edge finishing and surface preparation

Surface & Coating-Friendly Processing

- Suitable for plastic-coated sheets—deburrs edges while preserving the protective plastic layer (setup dependent)

- Suitable for foil-covered, zinc-plated, and other surface-sensitive parts (process setup dependent)