Buffing with paste

High glossy finish still requests a special polishing paste, which is applied to the strip surface.

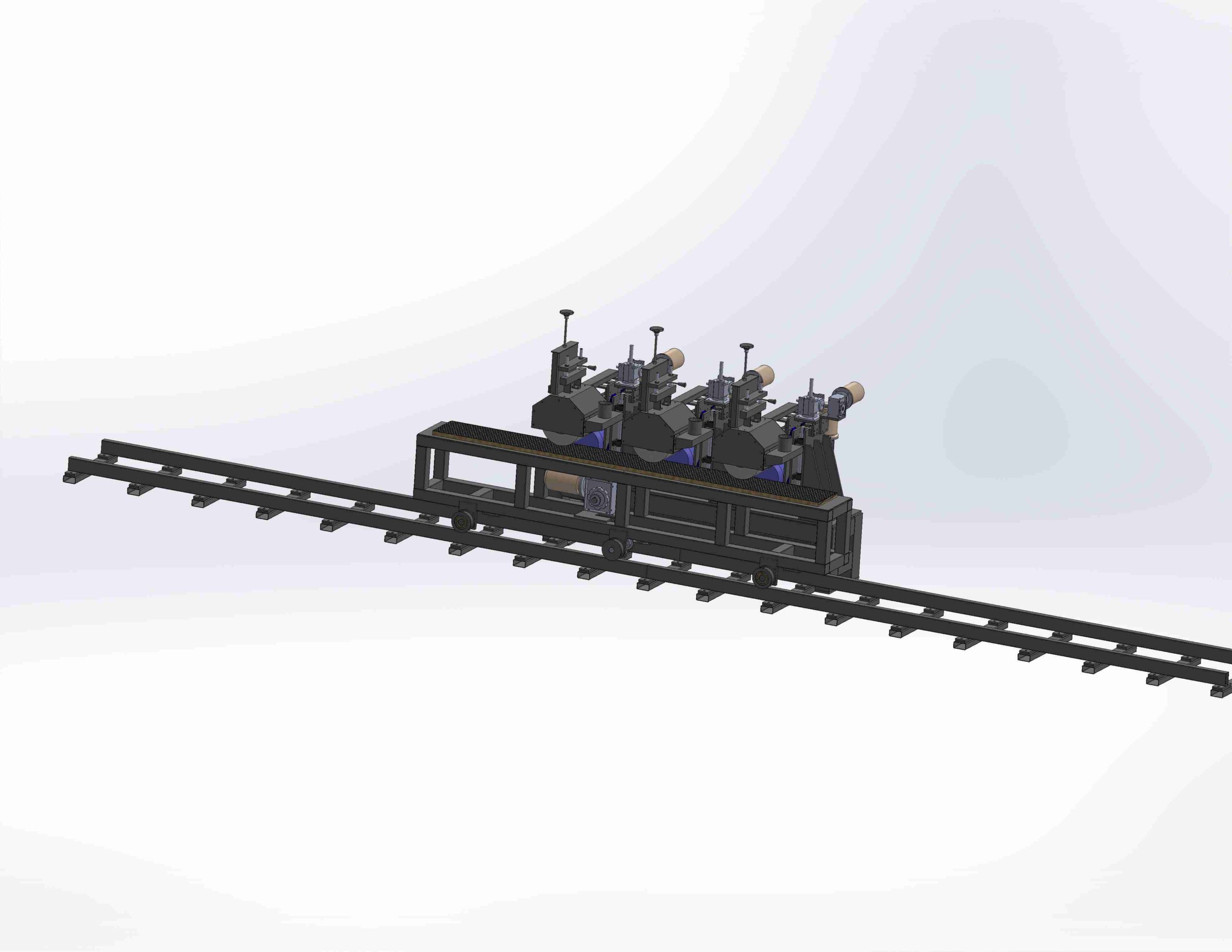

Feature :

- Environment Friendly

- High Working efficiency

- Compact Design

- Stable Oscillation System

- Adjustable Transmitting Speed

- Adjustable Polishing Pressure

- Fast Change of the Polishing heads

- Perfect Cleaning & Drying Unit

- Large Machine Space for Maintenance and Repairing.

- Easy Operation

Benefits:

- Liquid compound will be recycled and reused, No Compound leakage or Splash.

- Low Operation Cost.

- Machine parts are free from being etched by Polishing Compound.

- Vibration lines are avoided

- Forward and Backward Transmission

- Fast Change of the Polishing heads

- Automatic thickness Adjustment, With Manual Assistance

- No Watermark or dirt is left after Laminating

- Best Cost Performance

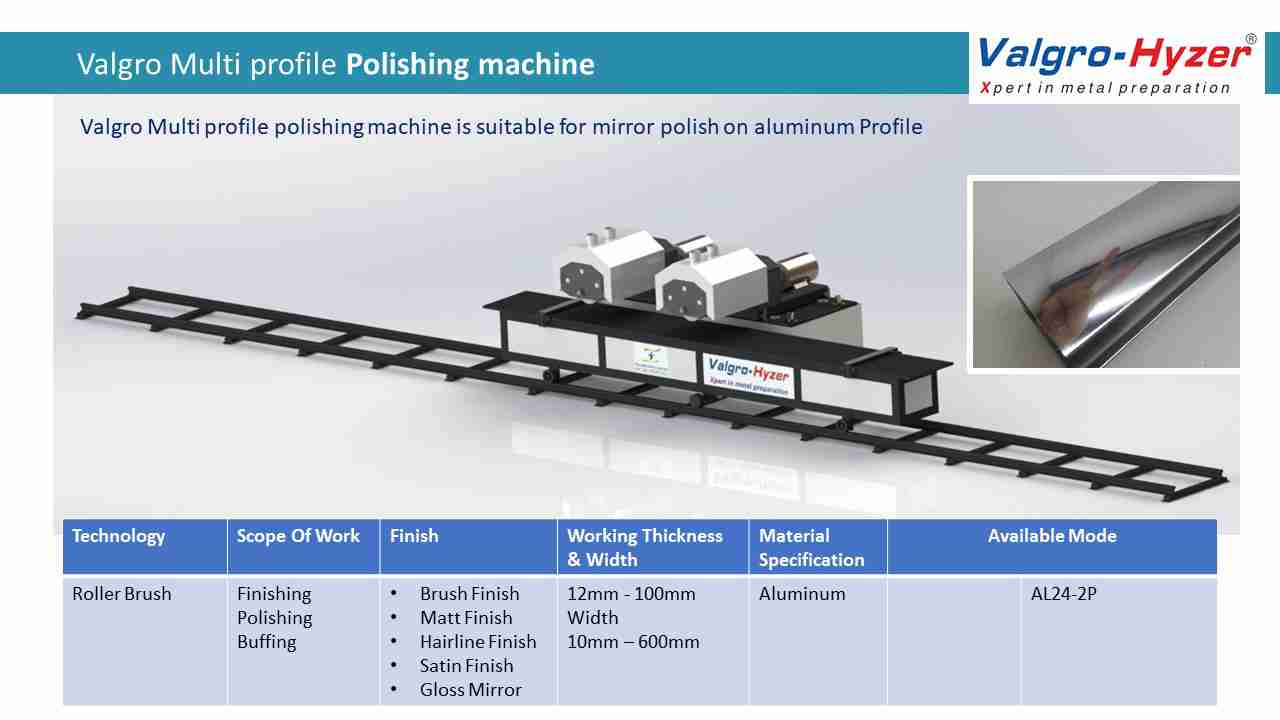

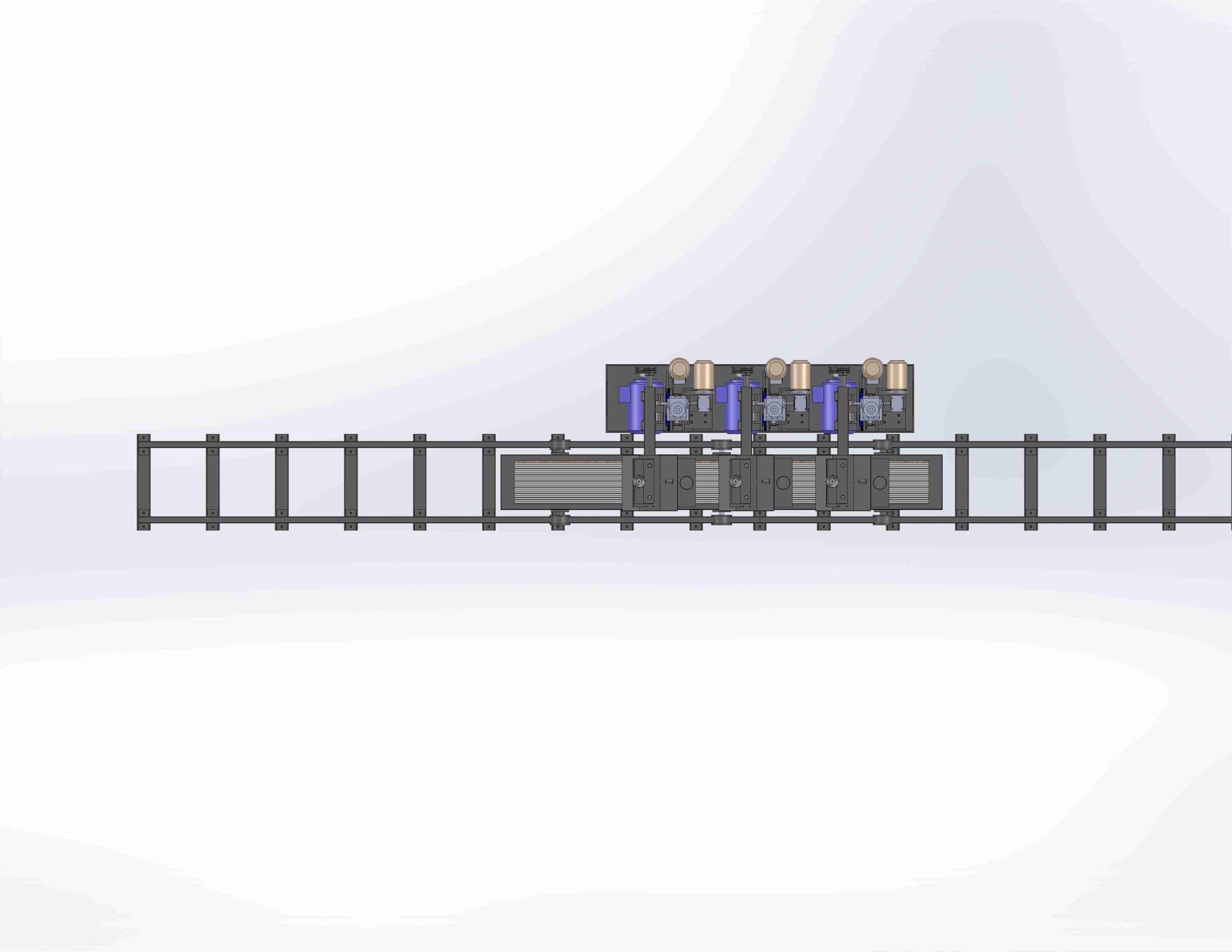

Technical Specification

Custom Design Model Please mail us for more detail sales@valgroabrasives.com

- Stainless Steel Gloss Mirror Polishing

- Alumnium Profile Polishing