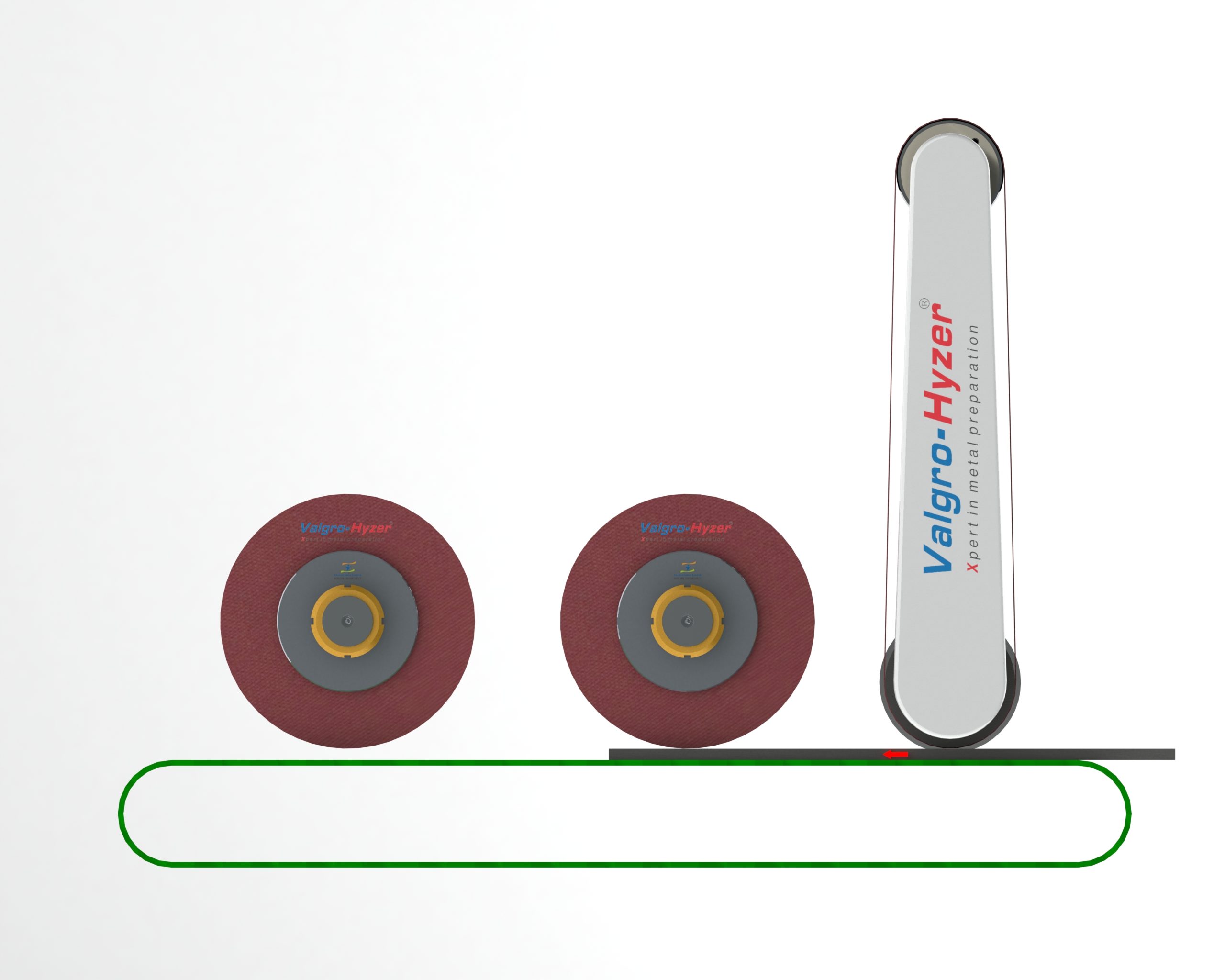

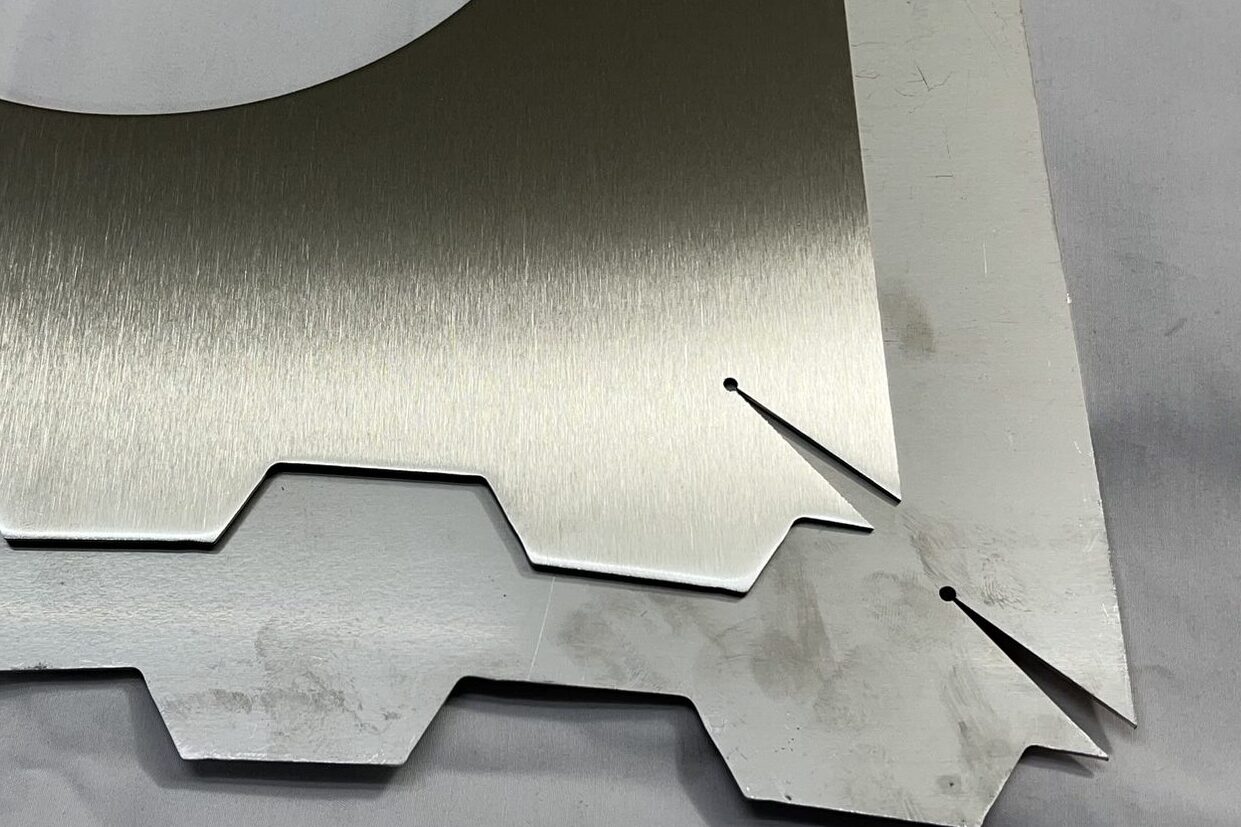

The SAMARTH Classic Hybrid Series is designed for precise metal finishing and deburring tasks, suitable for materials such as copper, brass, and stainless steel. This machine integrates belt and roller brush technologies, offering a comprehensive solution for achieving smooth, burr-free surfaces on sheet metal and other flat parts.

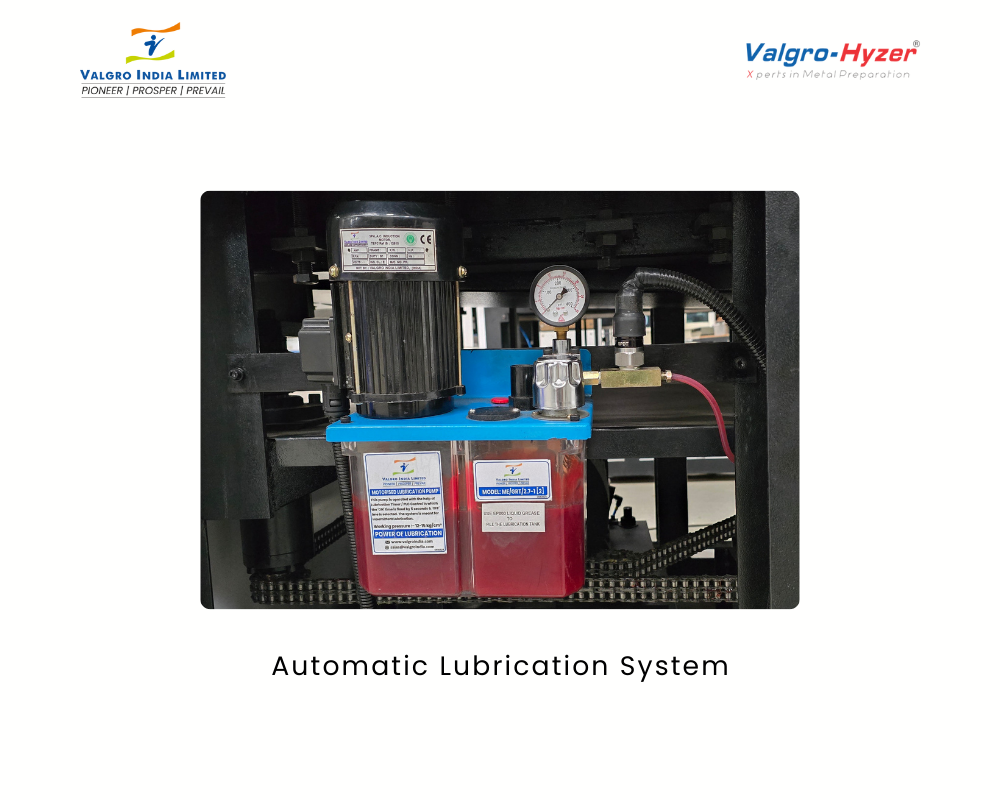

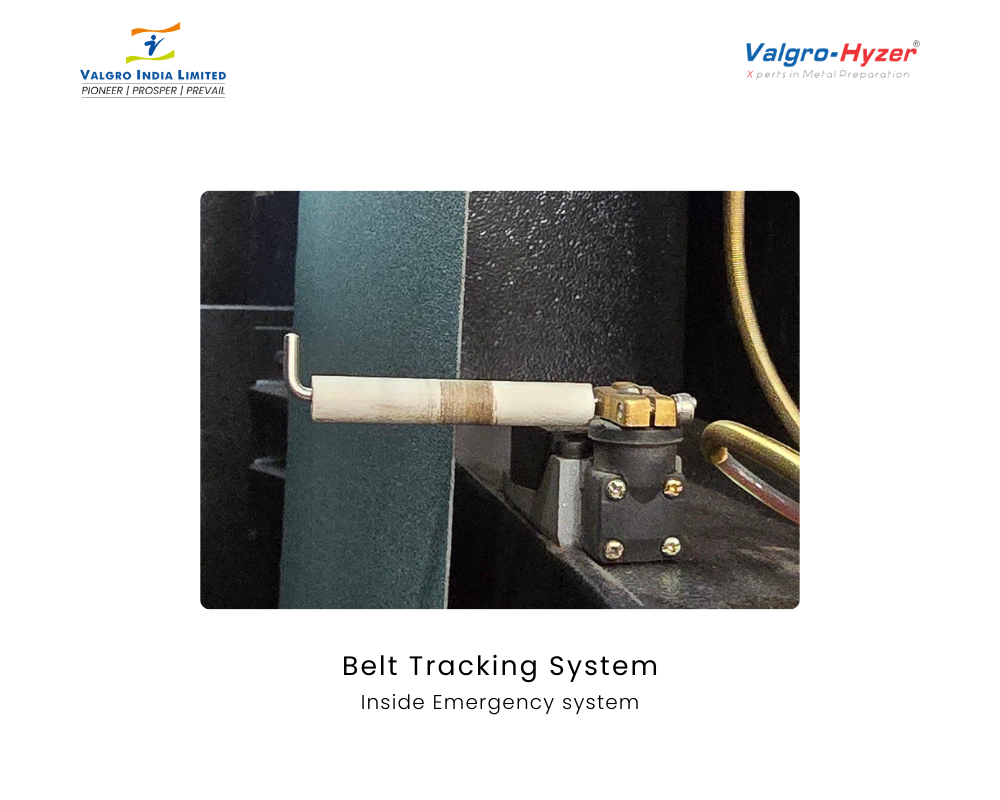

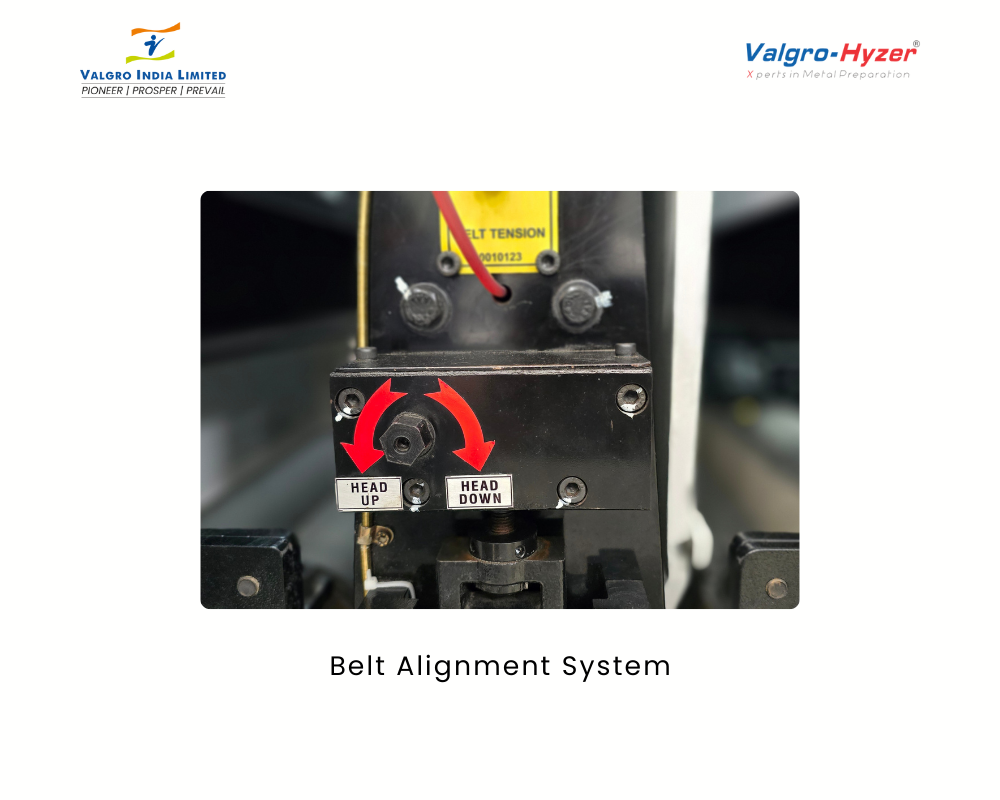

SAMARTH Classic Hybrid Series Deburring & Finishing Machine is available from 300mm to 1600mm with multiple head options. It offers dual infeed and outfeed pinch rolls to ensure parts feed throughout the machine uniformly. It is compatible with a Belt, all these accessories per your industrial requirements. Its thickness measurement control can be between 1mm to 50mm of parts. It can be configured with automatic abrasive belt tracking to ensure proper belt alignment during operations.

- Capable of handling a wide range of metals and finishes, making it suitable for various industrial applications.

- Wide Belt + Brush Mechanism: Ensures uniform sanding and finishing over a large surface area.

- Adjustable Pressure Settings: Allows for precise control depending on the thickness and type of material.

- Advanced Filtration System: Captures dust and particles, ensuring a clean working environment.

- User-friendly Interface: Simplifies operation with easy-to-use controls and settings.

- Separate electrical control for all functions,

- Dry operation dust extraction system

- Adjustable Pressure on Polishing station

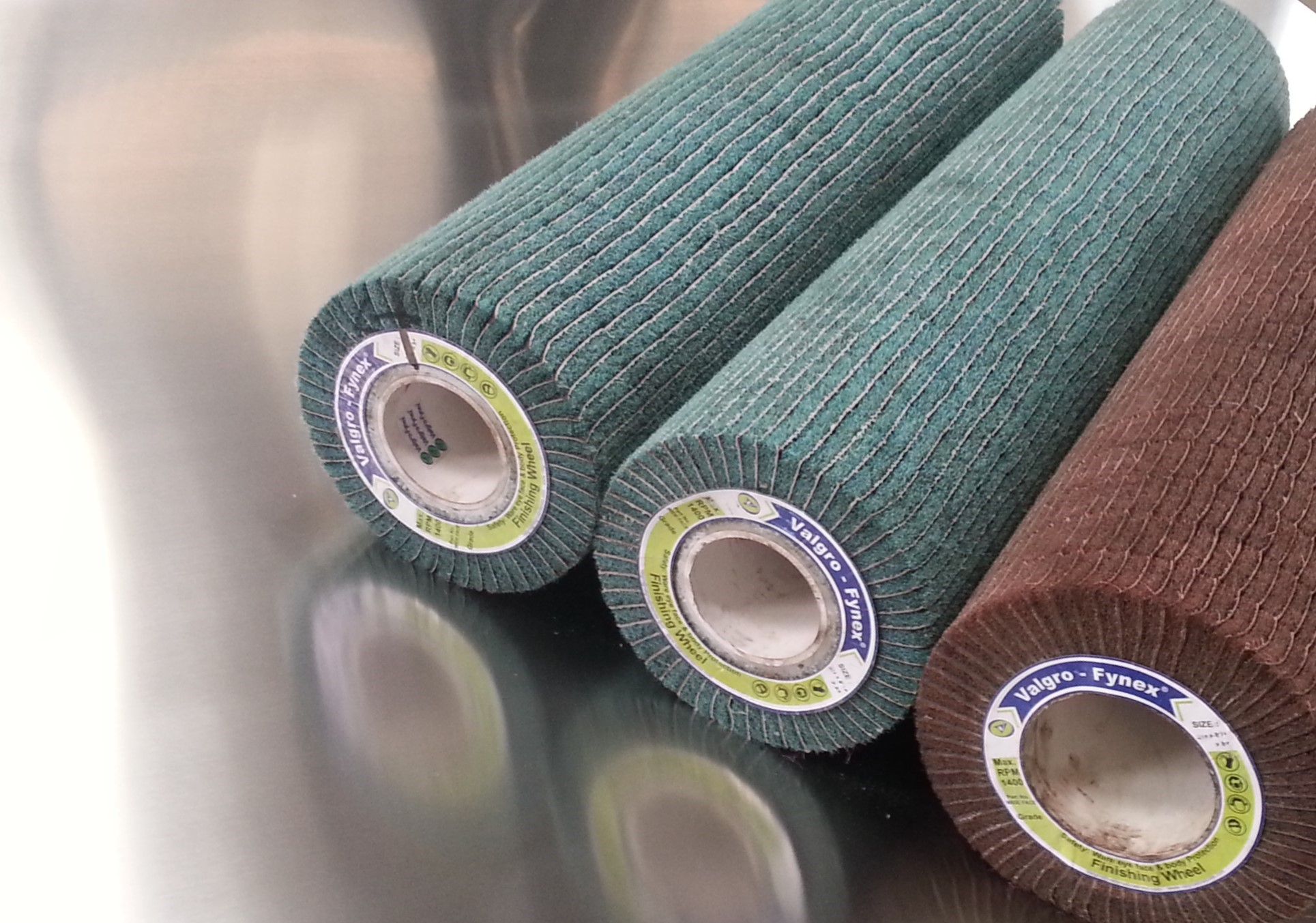

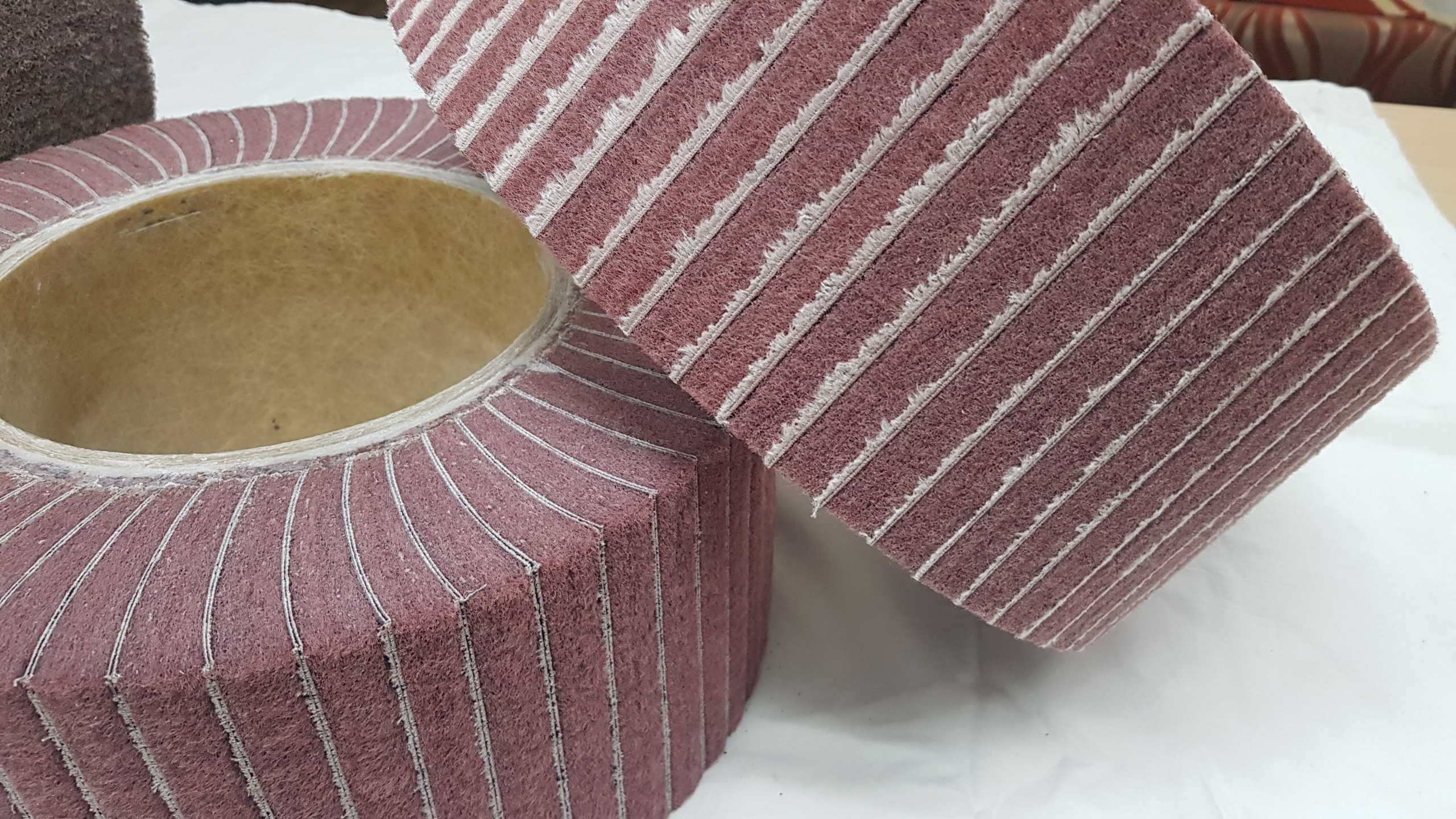

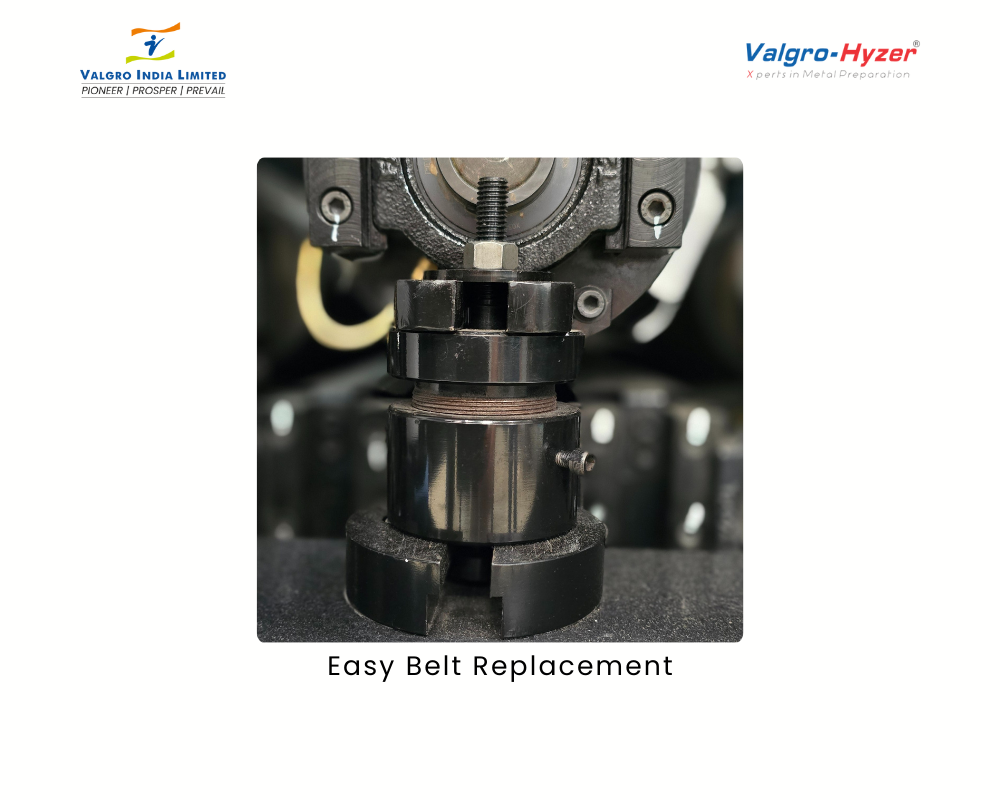

- Easy abrasive belt roller replacement

- Adjustable conveyor speed (belt/roller) from) 0.5 to 12MPM

- Surface treatment is possible with different grit combinations.

- Emergency security switch

Precision:

- High accuracy in deburring and finishing, ensuring high-quality output with minimal rework.

Efficiency:

- Reduces manual labor and increases throughput, optimizing production processes.

Cost-Effective:

- Provides advanced features at an affordable price, delivering excellent value for investment.

Safety:

- Equipped with safety features to protect operators during use, promoting a safe working environment.

Low Maintenance:

- Designed for easy maintenance with accessible components, minimizing downtime and repair costs.

- Metal Fabrication: Ideal for finishing and deburring metal parts in fabrication shops.

- Automotive Industry: Suitable for processing automotive components requiring precise finishing.

- Electronics: Perfect for deburring and finishing electronic enclosures and panels.

- Aerospace: Used for high-precision finishing of aerospace components.

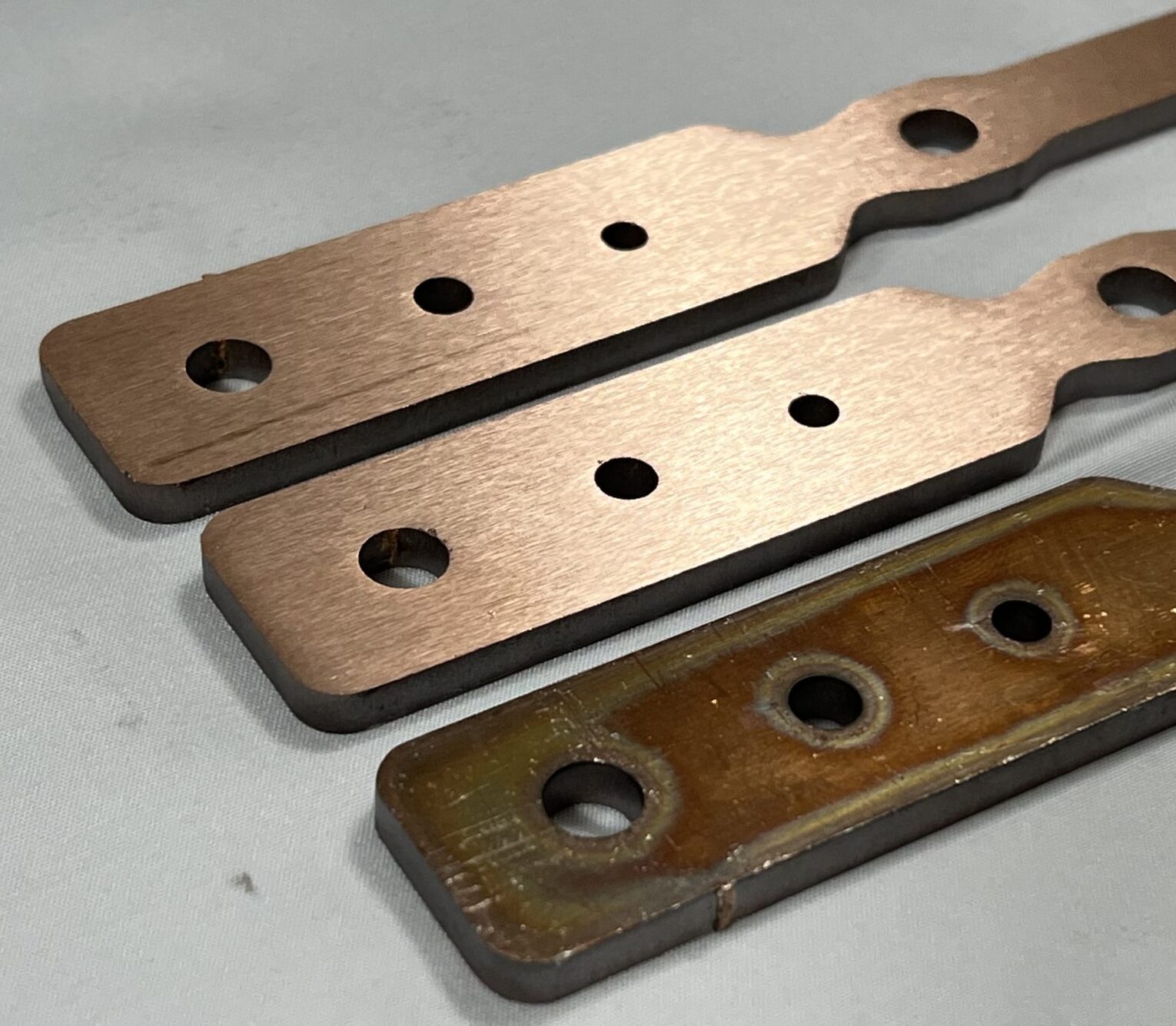

- Bus bar: Deburring punched, nibbled, sheared, or laser-cut sheet metal parts.

- Coating: Deburr and sand a radius to the sharp edge on cut out parts

- Plasma: Uniform sanding on all edges, leaving a fine scratch pattern on the surface.

- Marble: Deburring of all edges in one pass on laser cut or stamped parts

- Railway: Calibrating or keying carbon, rubber, wood, or other soft materials.

- Laser: Grain finishing and stock removal of any material.