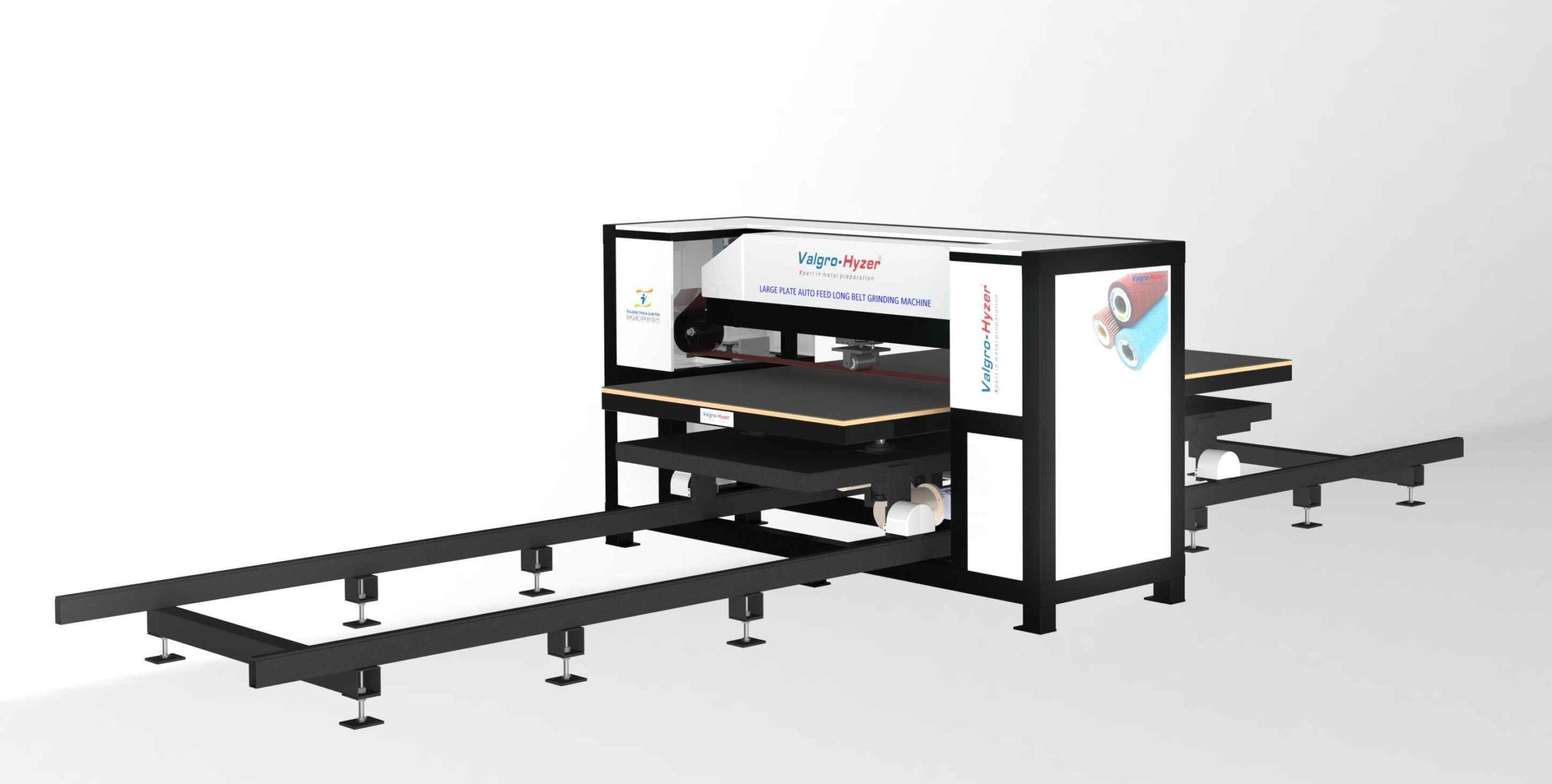

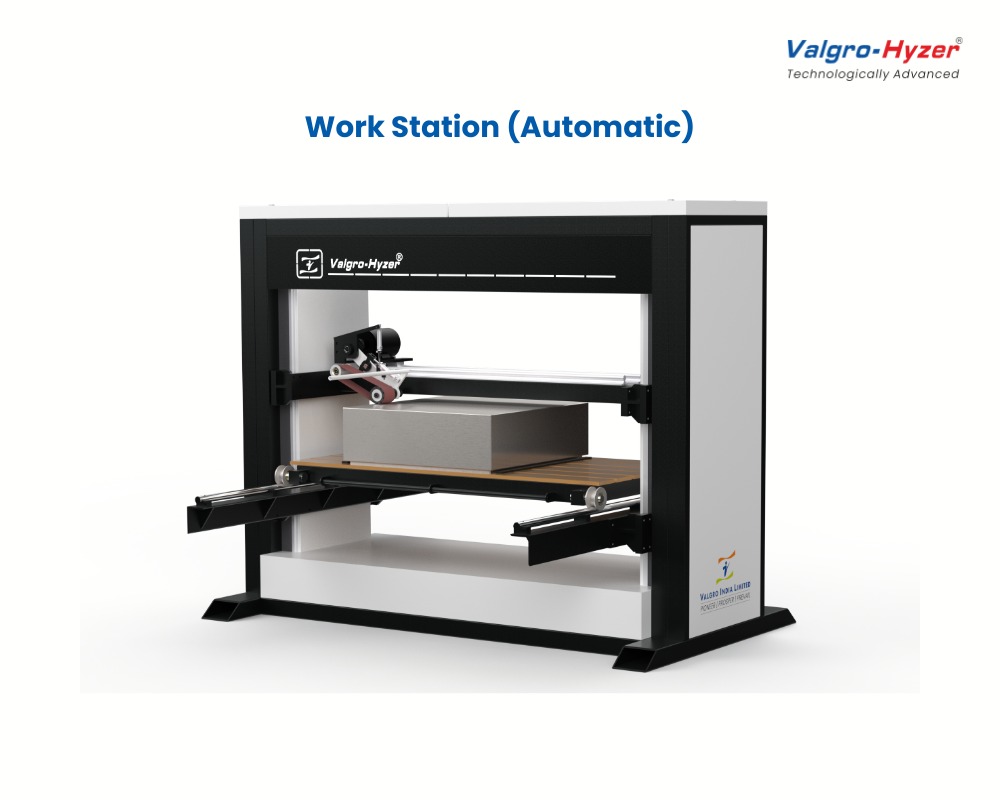

The Valgro Long Belt Sander stands out as a cost-effective solution for delivering precision finishing, enhancing productivity, and improving surface quality in fabrication environments

Key Advantages: The Valgro Long Belt Sander is equipped with advanced features that streamline the finishing process. Its flexible abrasive belt offers greater coverage and adaptability, making it suitable for handling oversized and flat workpieces with precision. The machine’s robust construction ensures durability and superior performance even during heavy-duty operations.

The Valgro Long Belt Sander is suitable for diverse applications across multiple industries:

Cabinets, Enclosures, and panels; Fabrications for home and kitchen appliance stries; Flat surfaces of considerable dimensions, Square and Rectangular Tubes, Tubular Structures

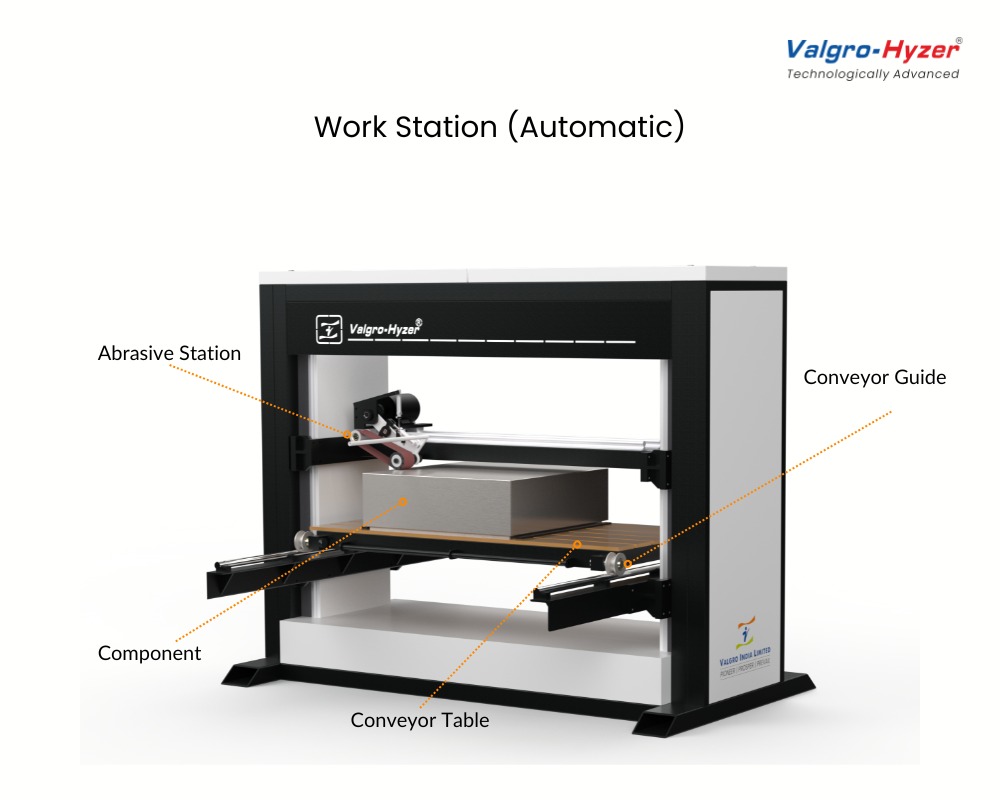

Key Features:

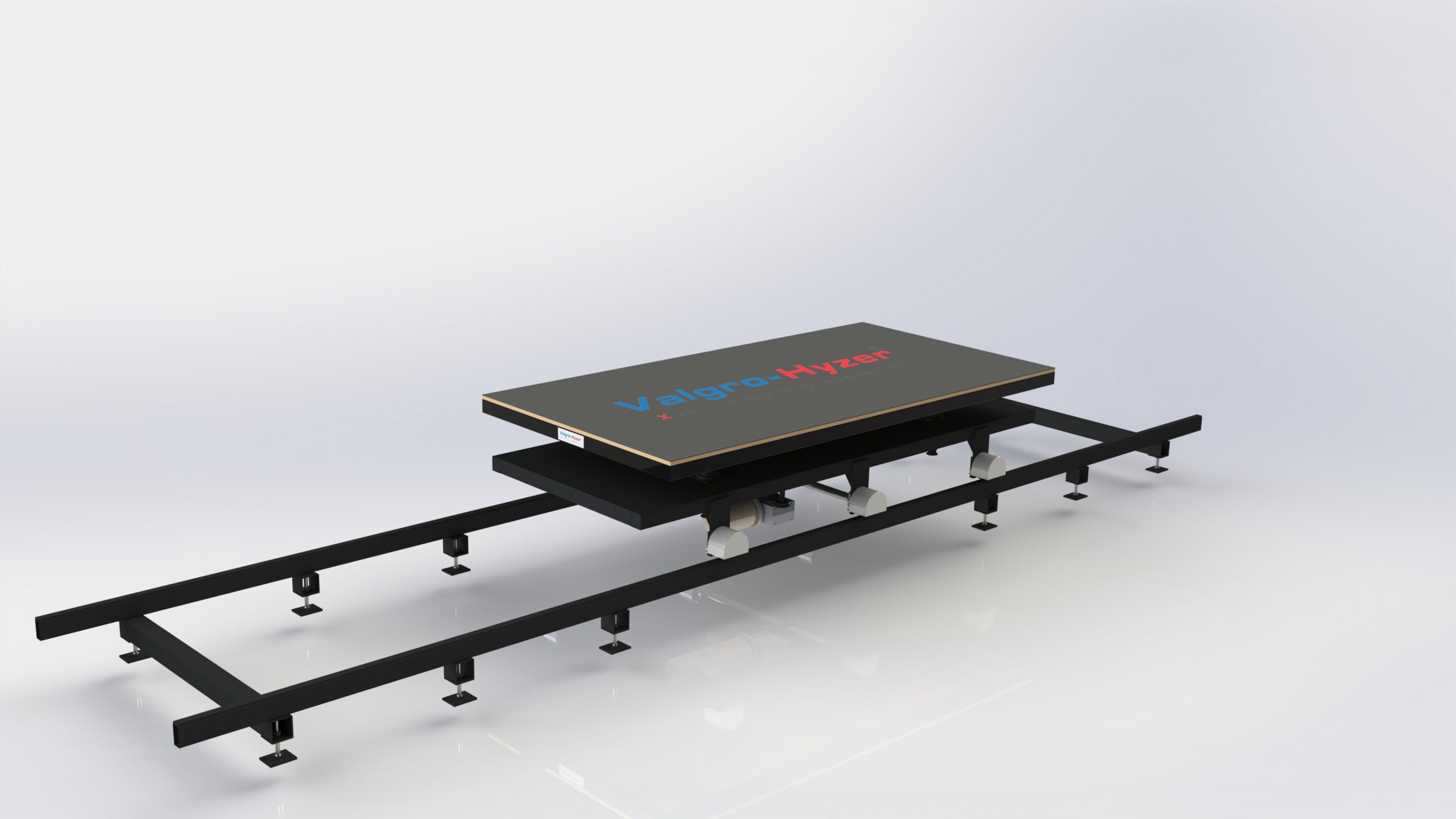

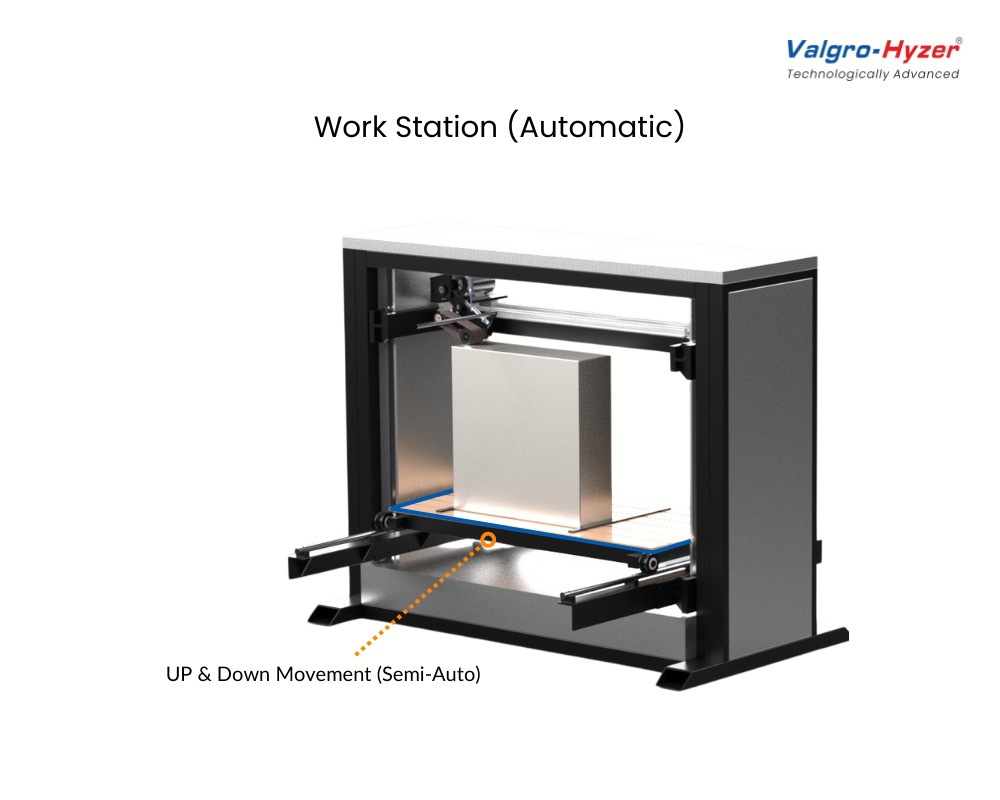

- Stable Tabletop Design: Ensures precision control and enhanced workpiece stability.

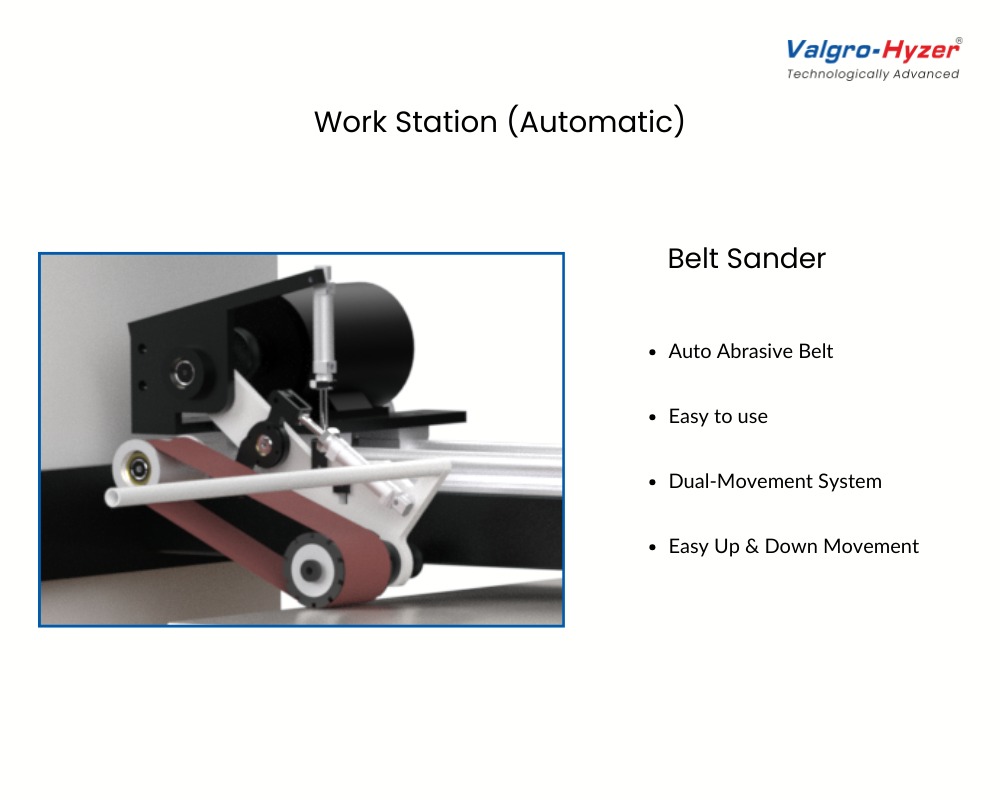

- Extended Belt Surface: Facilitates uniform finishing over larger surfaces.

- Flexible Abrasive Belt: Enables finishing on flat surfaces of big dimensions with a fully automatic function.

- Robust Design: Allows the machining of longer workpieces.

- Swiveling Grinding Unit: Usable as an edge grinding machine.

- 125 mm Balanced Belt Rollers: Ensure low-vibration drive for smooth operation.

- Easy Belt Adjustment: Quick and efficient sanding belt setup.

- High Belt Speed: Operates at 2800 RPM for effective material removal.

- Upper Sanding Sole with Graphite Coating: Enhances sanding performance and belt longevity.

- Movable Sanding Shoes: Ideal for sloping surfaces.

- Smooth-Running Grinding Table: Ensures stability under heavy loads for precise results.

- Optimal Price-Performance Ratio: Ensures value for investment.

- Additional Equipment:

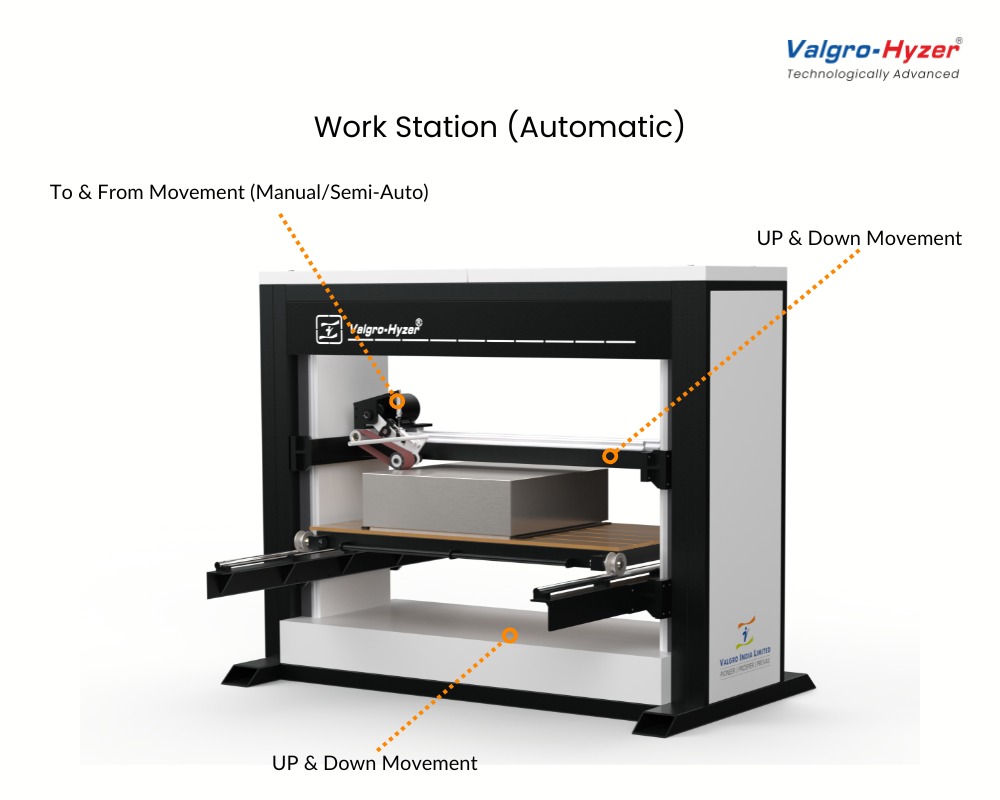

- Standard with electric table height adjustment.

- Ergonomically placed controls on a separate control panel.

- Standard with drawer grinding device for efficient dust collection.

Benefits:

- CNC Automation: Reduces dependency on skilled workforce.

- Smooth and uniform surface finish: ensures professional results on sheet metal.

- Unskilled labor operation: designed for user-friendly operation by non-experts.

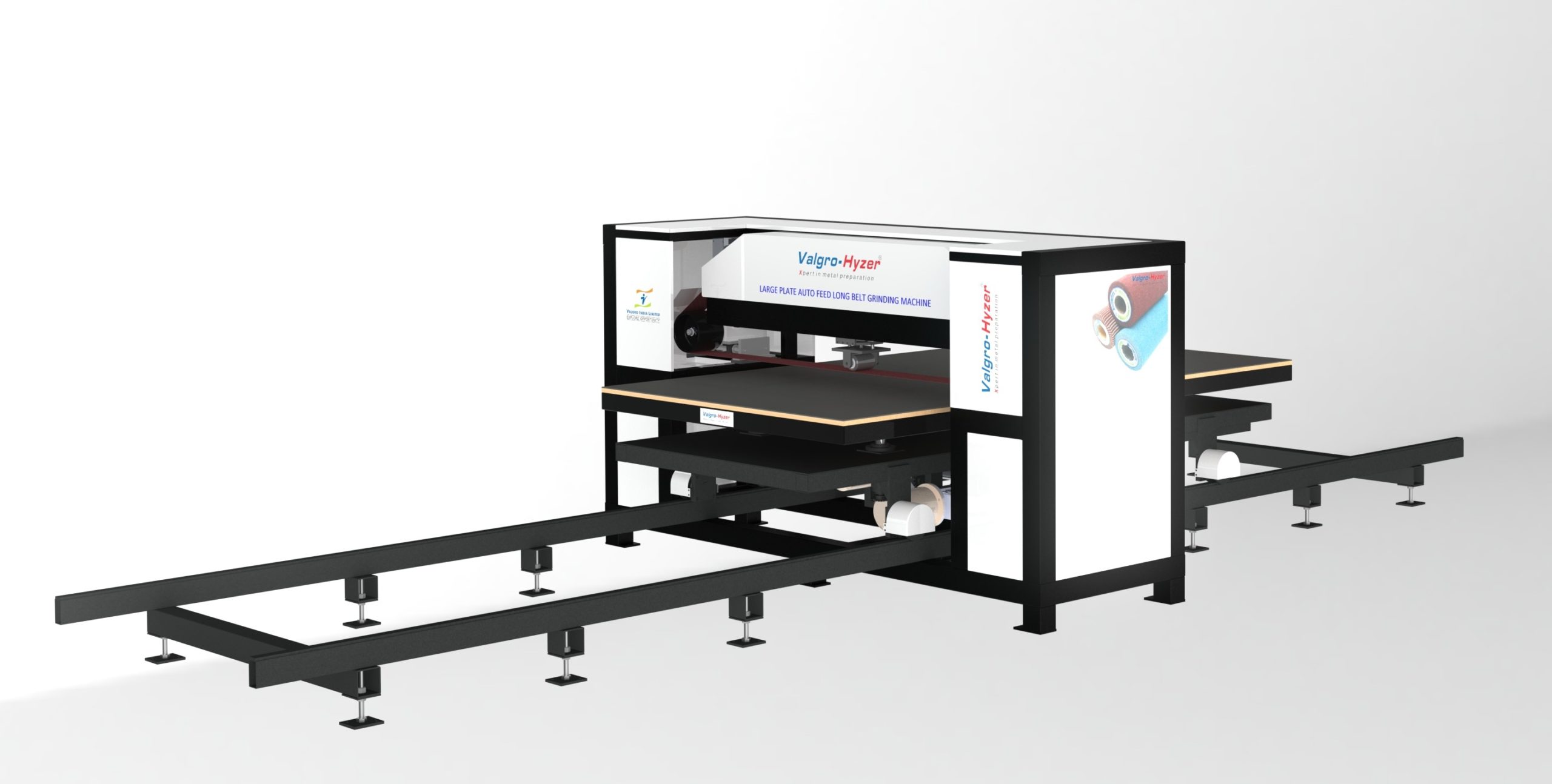

Custom design Model

Applications: Ideal for Cabinets, Enclosures, Panels, Fabrications, Home and Kitchen Appliance Industries. Suitable for flat surfaces of considerable dimensions, including:

- Sheet metal finishing

- Laser, Plasma, and Waterjet cut parts

- Square and Rectangular Tubes

- Tubular Structures

- Corners, Edges, and Weld Removal

The Valgro Long Belt Sander is a reliable and efficient tool designed to elevate your fabrication finishing standards, delivering smooth, refined surfaces that meet industry requirements.