In many industries, including automotive, construction, electronics, aerospace, and medical, high-quality wire cleaning after annealing is essential to achieve reliable, durable, and precision-ready products. During the annealing process, a layer of oxide scale forms on the wire’s surface, which can interfere with critical downstream processes such as coating, welding, or forming, affecting both the quality and longevity of the end product. A specialized annealed scale wire cleaning machine effectively removes this unwanted scale, enhancing surface quality and ensuring compatibility with further treatments.

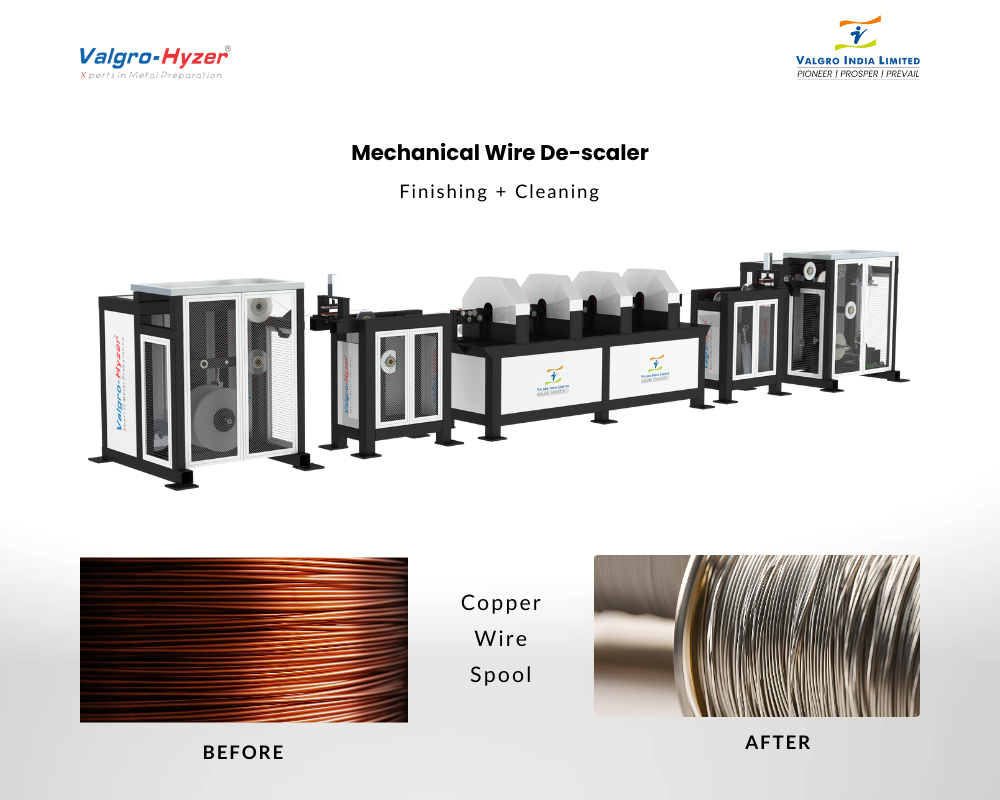

Effectiveness of Mechanical Wire Cleaning Machines

Mechanical cleaning machines are highly effective for annealed scale removal, offering benefits such as high throughput, precision control, cost efficiency, and an eco-friendly approach by eliminating harsh chemicals. These features make them a preferred choice in high-volume production environments where consistent and superior surface quality is critical.

By incorporating a mechanical wire cleaning solution, industries can streamline operations, reduce costs, and enhance product reliability, meeting stringent standards across diverse applications, including the demanding needs of the medical industry.

This comprehensive approach highlights Valgro India Limited’s dedication to quality and innovation in industrial surface preparation solutions.

Key Features & Benefits of the Annealed Scale Wire Cleaning Machine

• Advanced Abrasive Technology

Benefit: Provides precise, uniform cleaning without damaging the wire’s surface integrity, ensuring high-quality output that’s ready for further processing.

• Adjustable Cleaning Intensity

Benefit: Allows for customization to remove varying levels of scale, meeting the specific needs of different materials and applications, from automotive to medical industries.

• High-Speed Operation with Consistent Results

Benefit: Achieves fast processing speeds ideal for high-volume production while maintaining consistent quality, reducing downtime, and enhancing productivity.

• Environmentally Friendly, Chemical-Free Cleaning

Benefit: Eliminates the need for harsh chemicals, reducing environmental impact and creating a safer workplace. This eco-friendly feature also supports companies aiming to meet sustainability goals.

• Low Maintenance Design

o Benefit: Built for durability and easy maintenance, resulting in reduced operational costs and minimizing production interruptions, ideal for long-term, cost-effective use.

• Precision Control and Accuracy

Benefit: Precision in removing the exact level of scale required, ensuring the wire meets tight tolerances. This is crucial in applications where high performance and exact specifications are needed, such as medical and aerospace applications.

• Automated and User-Friendly Interface

Benefit: Simplifies operation, reducing the need for skilled labor and decreasing training time. Automation also improves efficiency by reducing human error and ensuring consistent output quality.

• Compact and Space-Saving Design

Benefit: Saves valuable floor space, making it suitable even for smaller manufacturing setups while delivering powerful performance comparable to larger machines.

Basic Parameters

- Payoff System

- Description: Heavy-duty payoff system designed for stable wire dispensing, ensuring smooth feed into the cleaning line.

- Wire Capacity: Configurable to accommodate various spool sizes and wire gauges.

- Speed Synchronization: Integrated with the cleaning system to maintain consistent speed throughout the process.

- Control Options: PLC-controlled for synchronized operations and speed adjustments.

- Tension Control System

- Description: Precision tension control to maintain optimal wire tautness during cleaning, preventing slippage or breakage.

- Adjustable Tension Range: Provides flexibility for different wire diameters and material properties.

- Sensor Feedback Mechanism: Real-time monitoring with feedback loops to maintain consistent tension, crucial for high-quality cleaning and wire integrity.

- Abrasive Cleaning System

- Description: Advanced abrasive cleaning technology for efficient and uniform scale removal.

- Abrasive Type: Configurable options including wide belt, brushing, or customized grit levels for different cleaning intensities.

- Cleaning Speed: Adjustable cleaning speed from 5-50 m/min to accommodate diverse wire processing requirements.

- Surface Roughness Control: Precision settings to achieve desired surface finish (e.g., specific Ra values), tailored for applications in automotive, medical, and construction industries.

- Dust & Waste Collection: High-efficiency filtration system for dust and debris capture, ensuring a clean and safe operating environment.

- Take-Up System

- Description: Robust take-up mechanism for collecting processed wire, ensuring smooth winding without tangling or damage.

- Capacity: Capable of handling various spool sizes, with adjustable winding speeds for different wire types.

- Automatic Winding Control: Features automatic tension adjustment and layer control to maintain neat and consistent winding, facilitating efficient downstream handling.

- Control System

- Automation and Monitoring: PLC-based system with a touchscreen interface for easy operation, real-time monitoring, and precise control of all parameters.

- Integration: Fully integrated control over payoff, tension, cleaning, and take-up systems for seamless and synchronized operation.

- Safety Features: Emergency stop, safety enclosures, and interlock systems to ensure a secure and compliant working environment.

Annealed scale wire cleaning machines have applications across several sectors:

- Automotive: A clean surface is essential for processes like welding and bonding for wires used in structural and safety components.

- Construction: Scale-free wires are often required in reinforcing mesh, cables, and fasteners.

- Electronics: Electrical and telecommunications industries use cleaned wires to ensure conductive quality and minimize signal interference.

- Aerospace: Cleaned wires are essential in critical applications where high performance and safety standards are mandated.

- Medical: In the medical field, precise and contaminant-free wires are required for instruments, implants, and surgical tools. Cleaned wires ensure that medical devices meet stringent safety and performance standards, offering:

Application in Medical Industries and Its Benefits

In the medical field, precise and contaminant-free wires are required for instruments, implants, and surgical tools. Cleaned wires ensure that medical devices meet stringent safety and performance standards, offering:

- Enhanced Biocompatibility: Scale-free wires help in producing medical devices that are safer for implantation and minimize potential adverse reactions in patients.

- Improved Reliability: Clean surfaces contribute to the overall durability and accuracy of medical devices, essential for life-saving and minimally invasive applications.

- Optimal Surface for Coatings: With clean wire, medical-grade coatings, such as antimicrobial or biocompatible layers, adhere better, ensuring optimal functionality and safety.