Help to remove most historical problems

Un-pickled Patch l Oxide l Carbon Suit l Oil Patch l Black Spots l Rusty Surface l Mill Scale l Scratch l Rolled in Scale

Our Field trial has proved that saving on pickling chemical cost reduction to the tune of 70% to 75% can easily be obtained by reducing concentration of chemical.

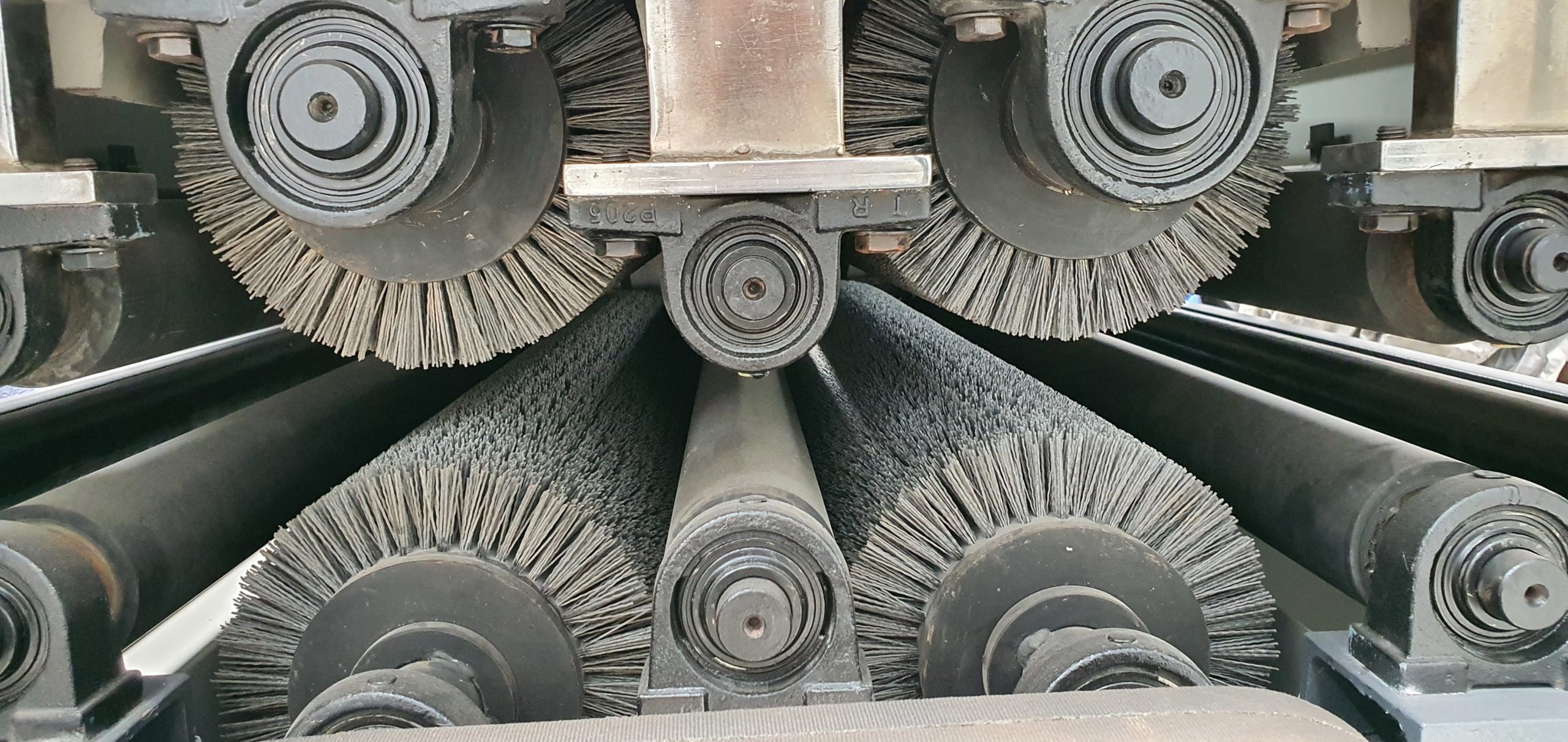

Feature:

- Various hardnesses

- Wide range of grit size and grain selection

- Temperature resistant

- Also available as longlife impregnation

- Flexibility adjustable

- High Edge stability

- Reproducible surfaces

- Balanced

Advantages :

- Increase surface value with Uniform cleaning Quality

- Consistent scratch pattern for coating operation

- Rust and Oxide free Surface

- Self dressing throughout the brush life

- Saving 70% to 75% on pickling chemical cost by reducing PH concentration

- Due to less chemical concentration reduce waste disposal

- Perfectly fit at de-greasing, de-scalling brushing station

- All these, in turn, increases productivity and reduces costs.

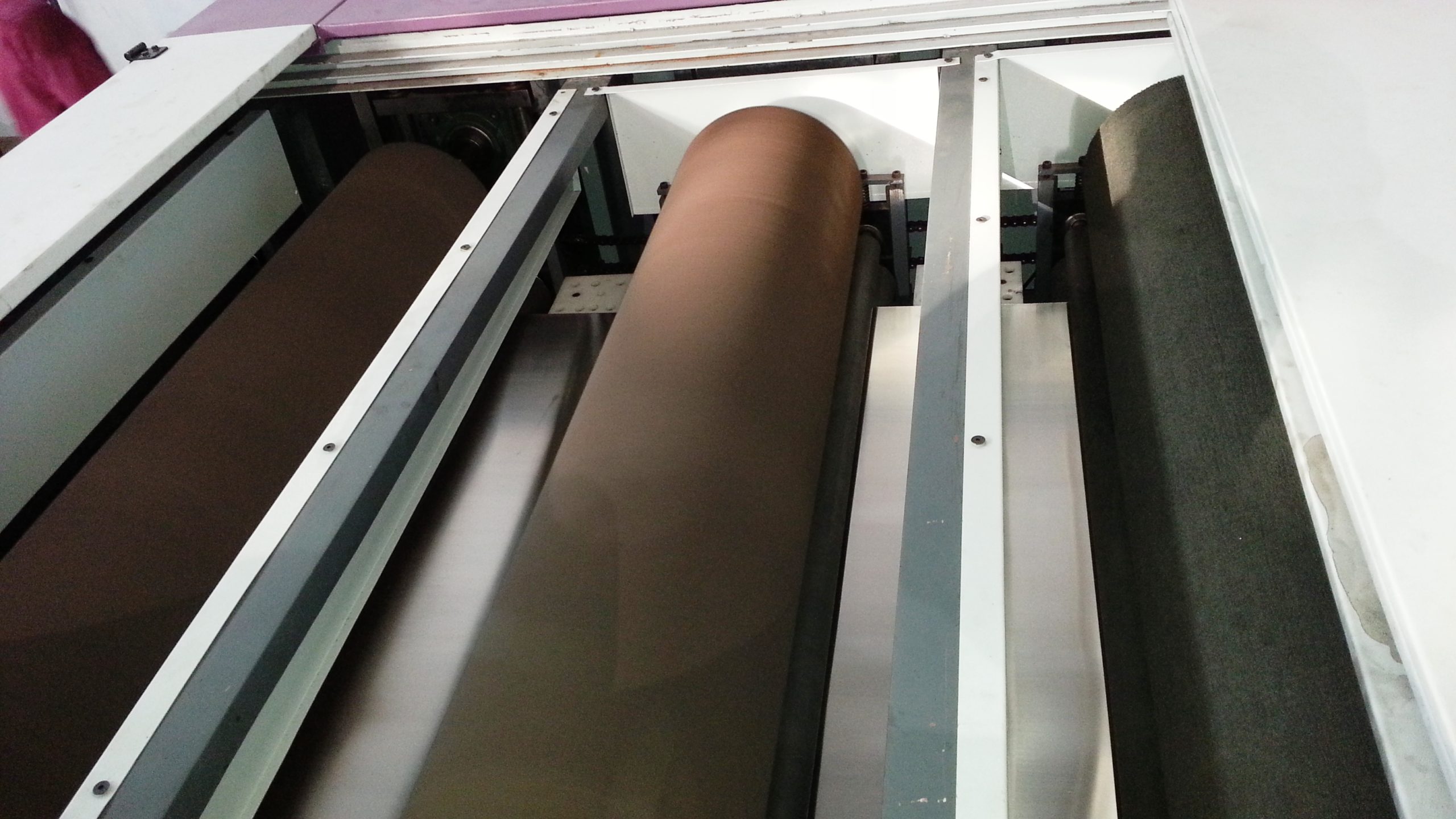

Technical Specification

Available Size OD: 300mm, 350mm, 400mm, 450mm, 500mm Width: 400mm to 2500mm Grade: CRS, MED, FN, VFN, SFN, NFN Special Size can be available on request.

Help to reduce the black carbon suits, Oil patch and other surface related problem which is normally try to removed with the use of hazardous pickling process.

- Effective removal of corrosion, burrs, dirt

- Decorative, even surface finish with a defined roughness depth, e.g. stainless steel, copper and brass

- Removal of punching and firing burrs with defined edge rounding

- Matting and satinizing various metal and plastic parts

- Descaling flame cuts

- Finishing