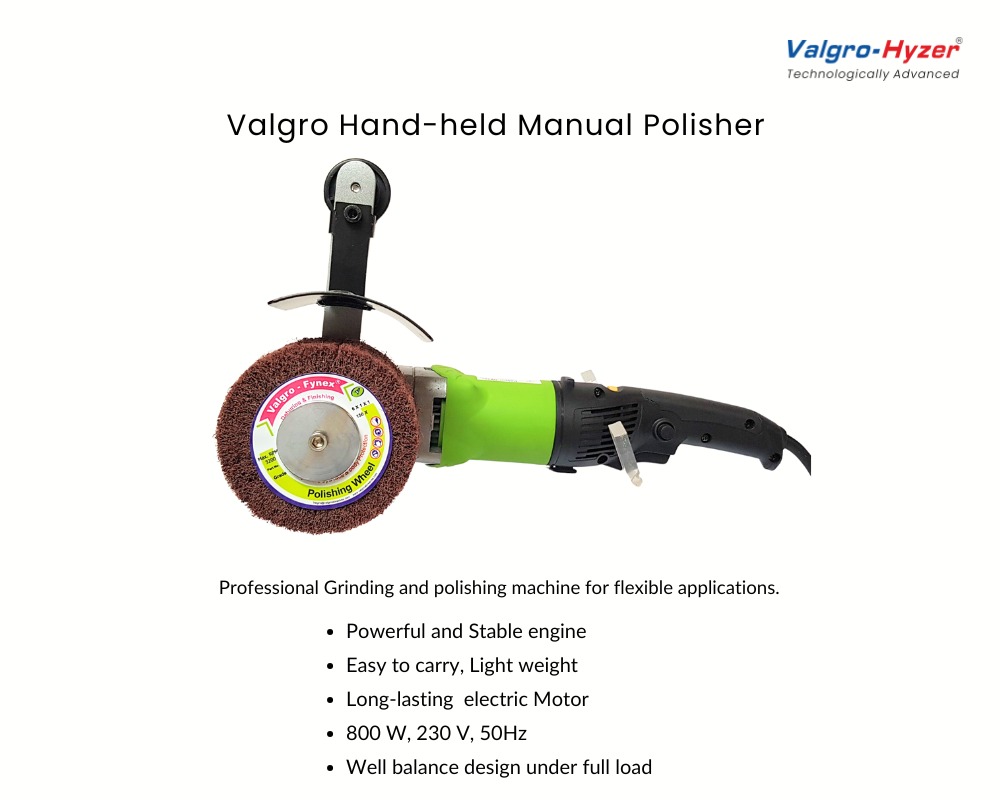

The Portable Burnishing Machine / Linear Polisher is an essential tool for achieving professional-grade finishes in various industries. Its ergonomic design, powerful motor, and versatile applications make it a reliable solution for enhancing surface quality and productivity. Ideal for workshops, construction sites, and fabrication facilities, this machine offers excellent value and performance in surface finishing operations.

The Portable Burnishing Machine is engineered to deliver consistent linear motion, making it ideal for achieving uniform finishes, deburring, and cleaning operations. Its ergonomic design and powerful motor ensure efficient material removal and finishing even on challenging surfaces.

The Portable Burnishing Machine is suitable for:

- Metal Finishing: Ideal for polishing, deburring, and surface preparation on steel, aluminum, copper, and brass components.

- Weld Seam Blending: Efficiently smooths out weld lines for improved aesthetics and structural integrity.

- Wood Finishing: Achieves smooth textures and uniform grain patterns.

- Rust Removal: Effectively removes rust, oxidation, and stains from metal surfaces.

- Surface Conditioning: Prepares surfaces before painting, coating, or anodizing.

- Pipe and Tube Finishing: Suitable for polishing round surfaces with special attachments.

Key Features

- Marathon Motor: Equipped with dust protection for extended service life.

- Vario-Tacho-Constamatic (VTC) Electronics: Maintains customized speeds suited to application materials, even under load.

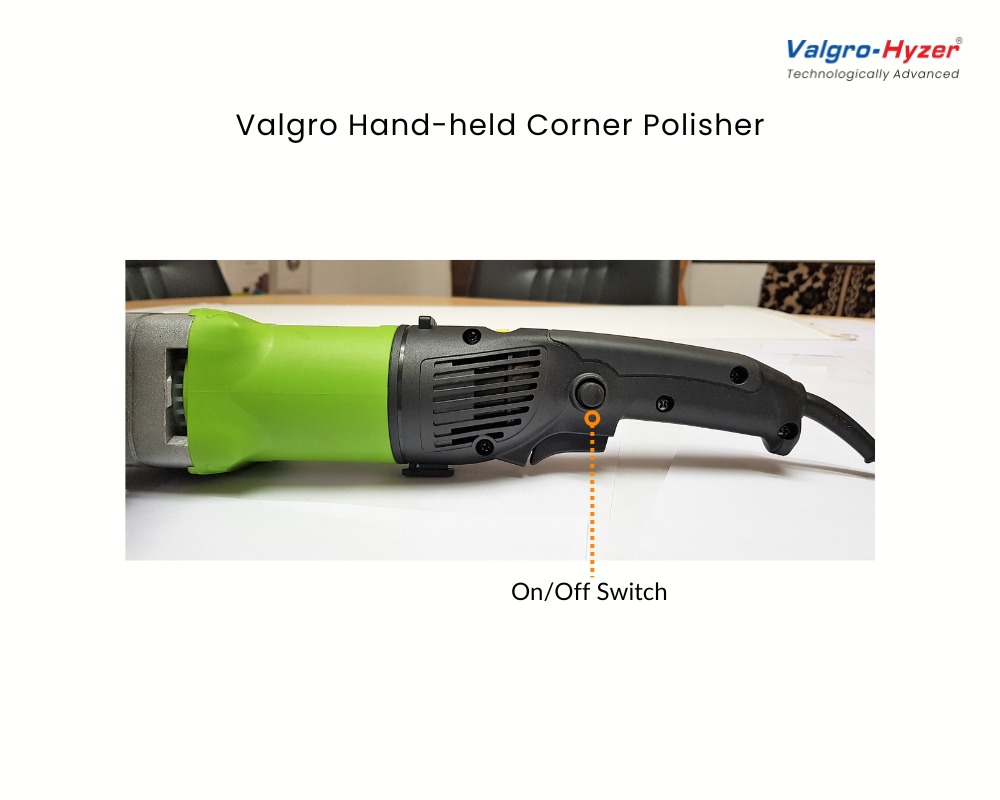

- Spindle Lock and Tool-Free Flange Nut: Enables fast accessory change without tools.

- Quick and Tool-Free Adjustment: Guard and side handle adjustments for ease of use.

- Smooth-running Arbor: Ensures a uniform grinding result.

- Overload Protection: Prevents motor overheating.

- Electronic Soft Start: Provides a smooth start-up.

- Restart Protection: Prevents accidental start-up after a power supply interruption.

- Auto-Stop Carbon Brushes: Protects the motor from excessive wear.

Benefits

- Achieves consistent and uniform surface finishes.

- Provides linear texturing, satin finish, hairline finish, and streak-free matt finish.

- Efficiently cleans dirt, removes scratches, and eliminates tarnishing.

- Effectively removes welded seams and prepares surfaces for coating or painting.

- Enhances productivity by reducing manual effort.

- Ensures improved aesthetics and structural integrity for metal surfaces.

Technical Specifications

Rated Input Power: 800 W

No-load Speed: 800 – 3000 RPM

Spindle Diameter: 19mm

Abrasive Tool Diameter: 115mm OD x 100mm Width x 19mm ID

Weight (without power cable): 1.9 kg @

Cable Length: 2 m / 6 ft @

Noise Emission:

Sound Pressure Level: 91 dB(A)

Sound Power Level (LwA): 102 dB(A)

Uncertainty of Measurement K: 3 dB(A)

Applications

The Portable Burnishing Machine is suitable for:

- Stainless Steel Fabrication

- Kitchen & Restaurant Equipment Manufacturing

- Dairy Equipment Production

- Food Processing Machinery

- Pharmaceutical Processing Machinery

- Packaging Machinery

- Beverage Equipment Production

- Escalators, Elevators, and Doors

- Public Transport Systems

- Metro and Railways

- Shipbuilding

- Automotive Industry

- Architectural Building Construction