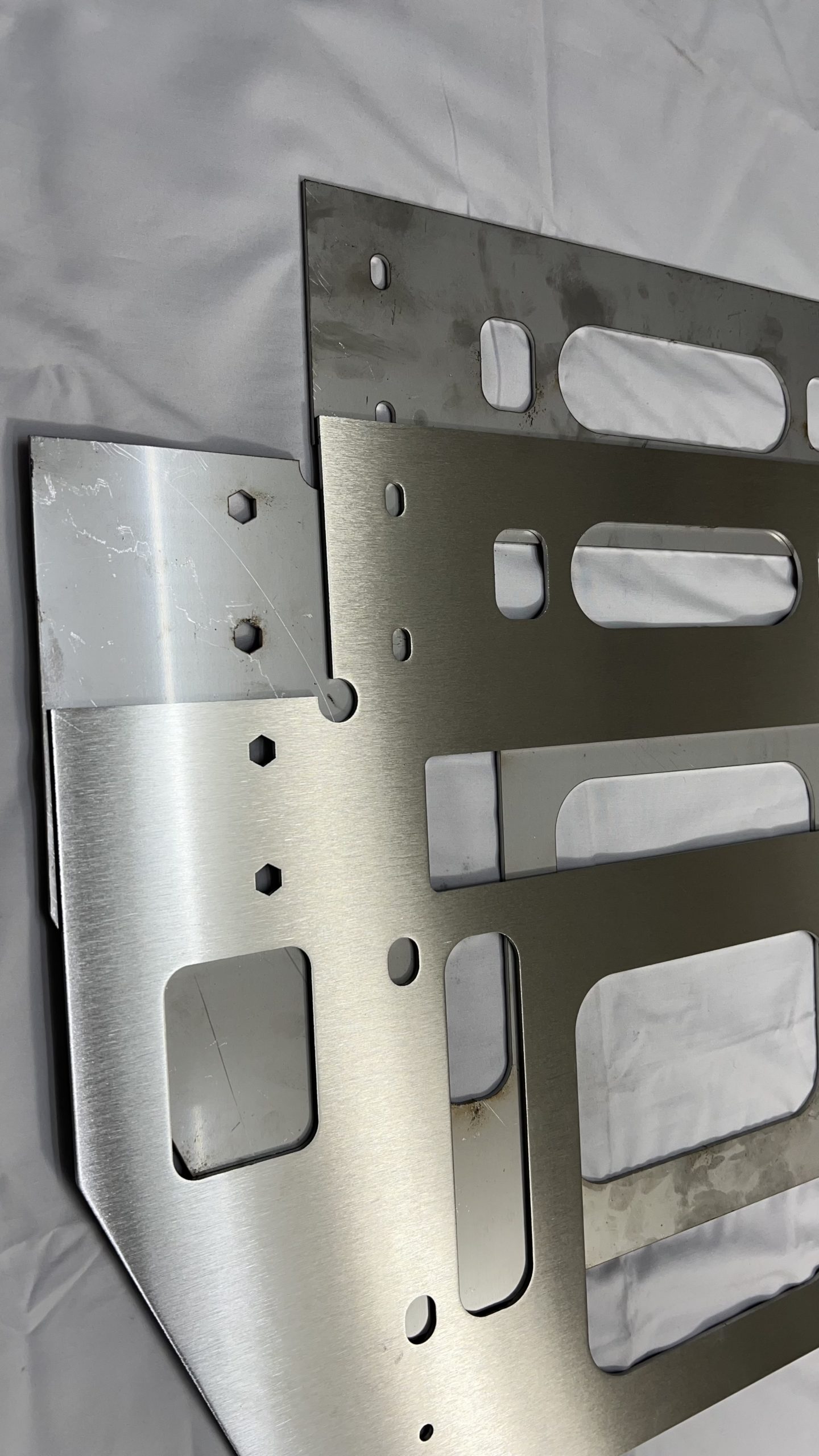

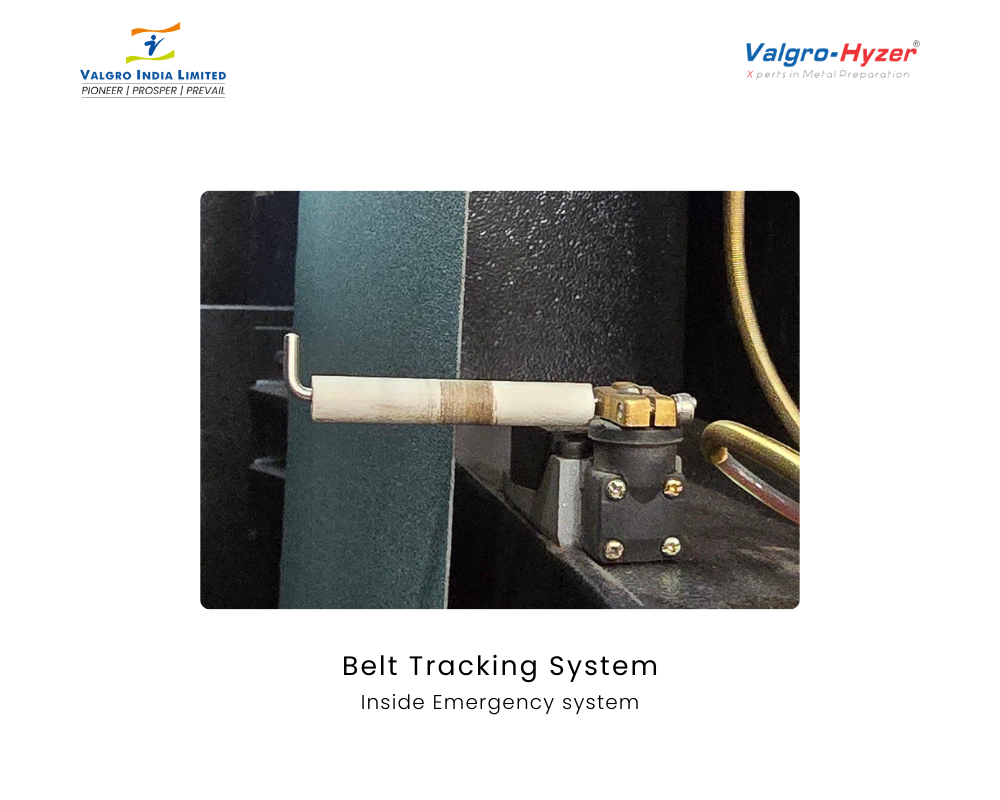

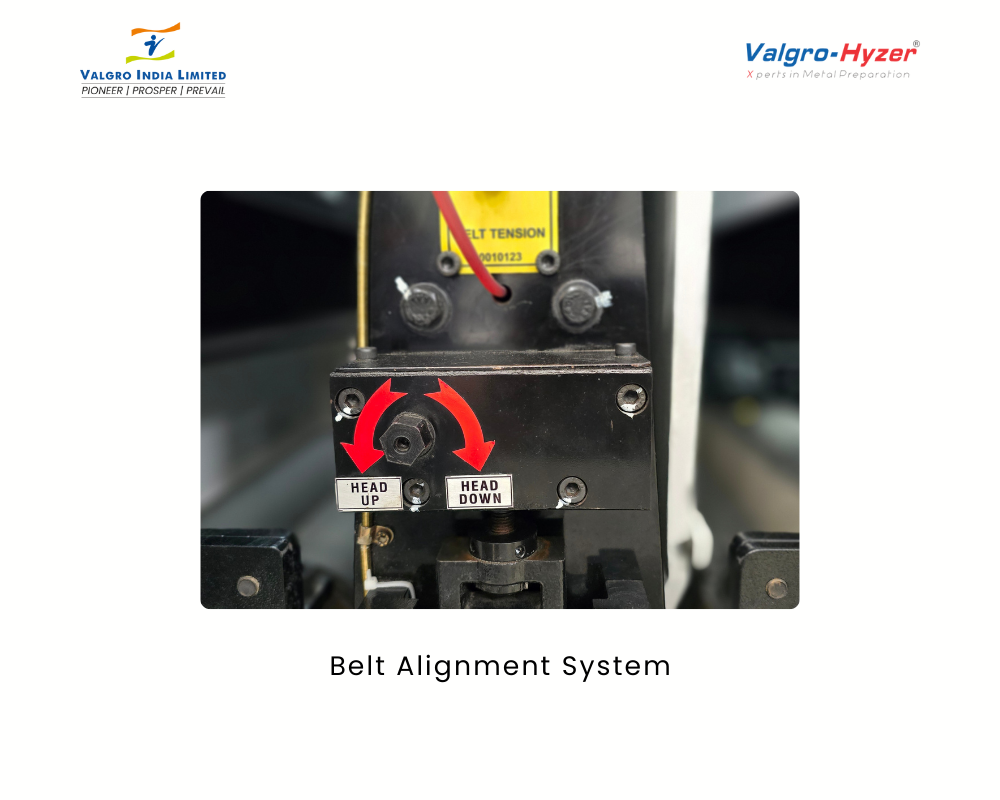

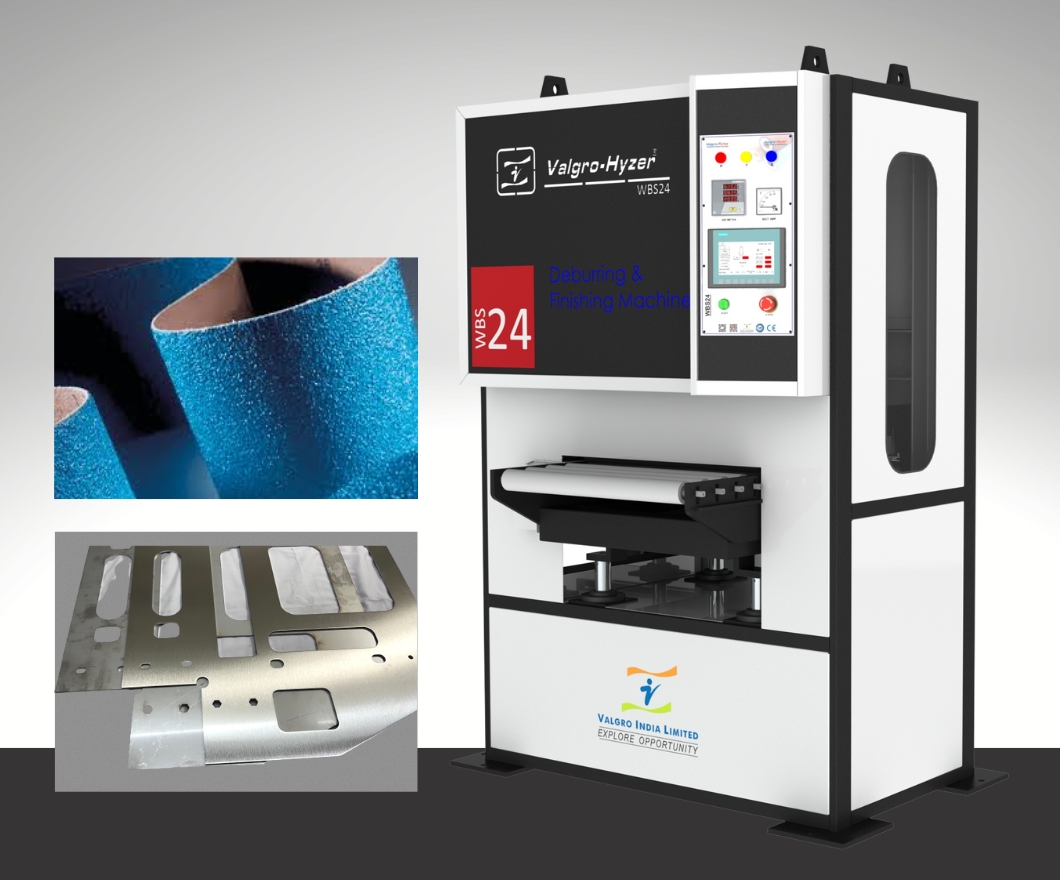

The Samarth Classic Series Deburring and Finishing Machine has head sizes ranging from 600mm to 1600mm, as well as dual pinch wheels for even feeding. It’s belt-compatible and designed for industrial use, handling parts ranging from 0.8 mm to 12 mm thick. It also includes automated abrasive belt tracking for optimal alignment.

Advantages

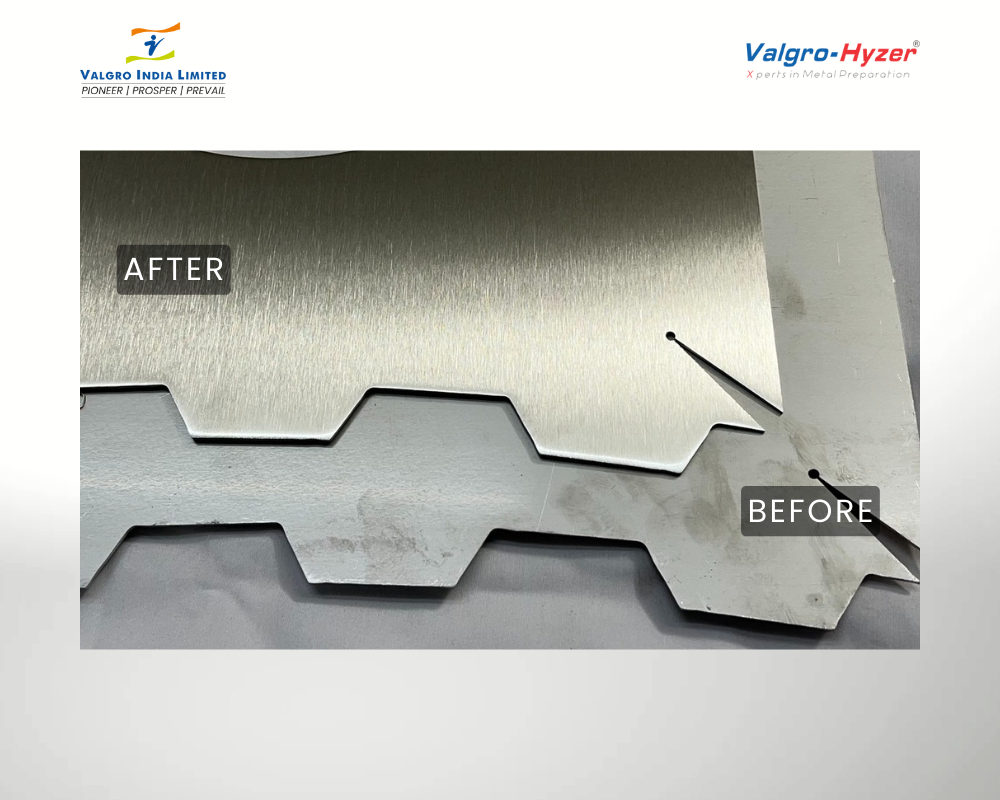

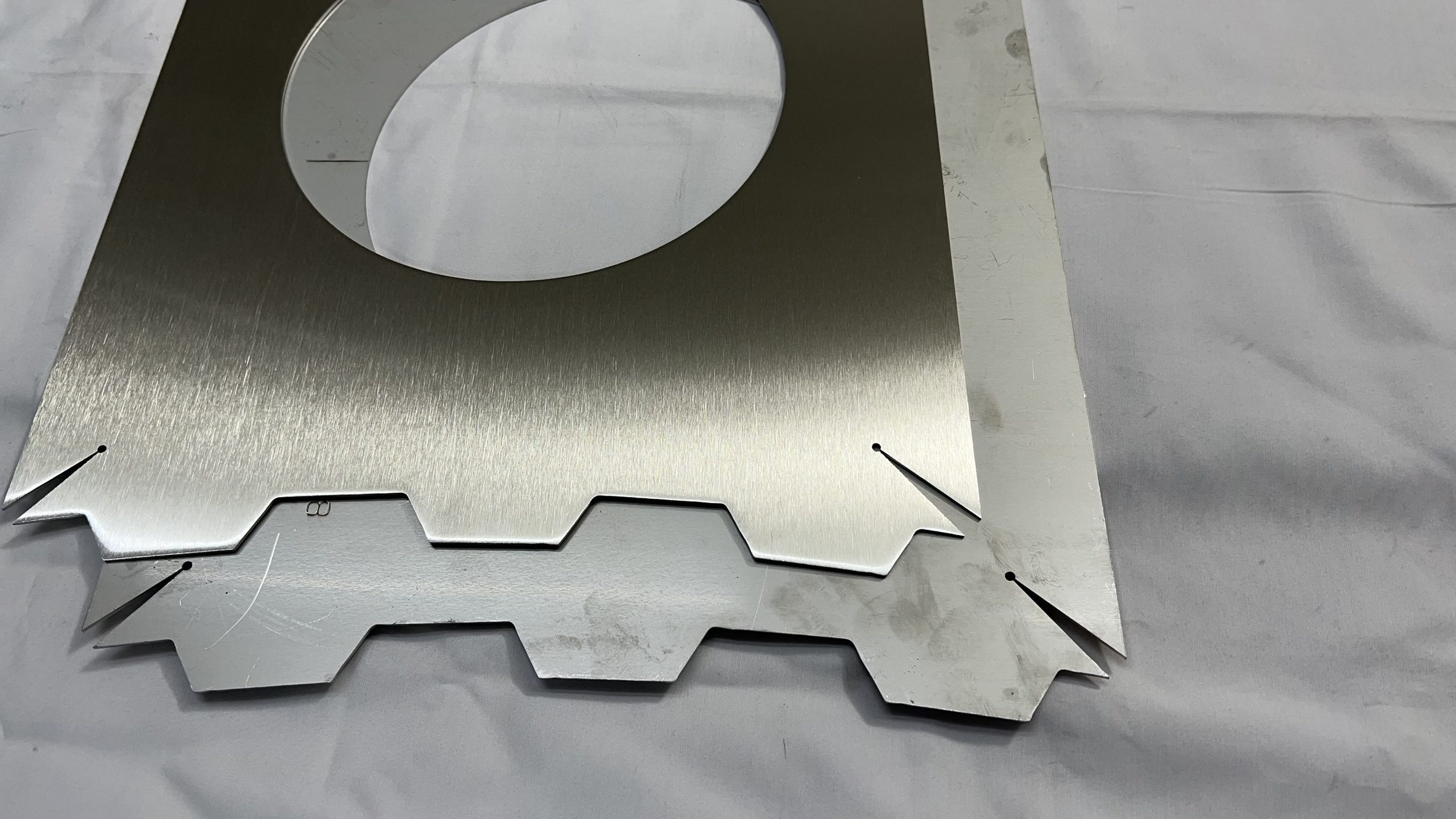

- Superior Finish Quality: Achieves a high-quality finish on stainless steel laser-cut parts, enhancing appearance and functionality.

- High Efficiency: Reduces processing time with a robust and reliable sanding mechanism.

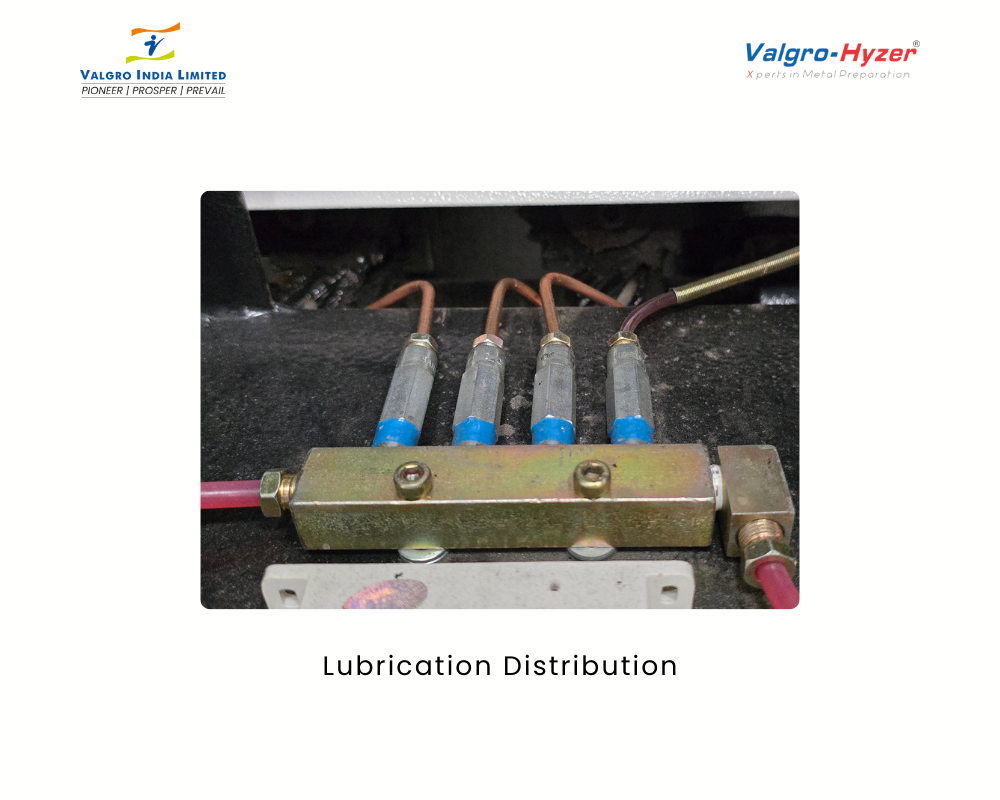

- Cost-effective Operation: Low maintenance and operational costs due to durable components and efficient design.

- Safety Features: This includes emergency stop buttons, protective guards, and safety interlocks to ensure operator safety.

- Wide Belt Mechanism: Ensures uniform sanding and finishing over a large surface area.

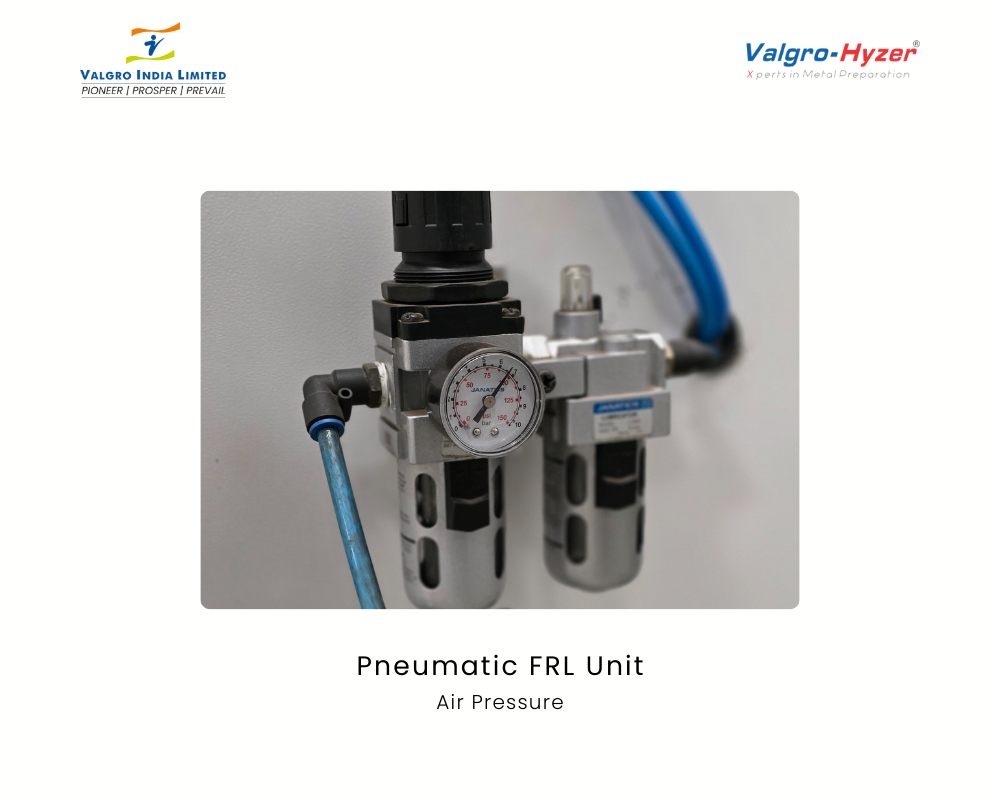

- Adjustable Pressure Settings: Allows for precise control depending on the thickness and type of material.

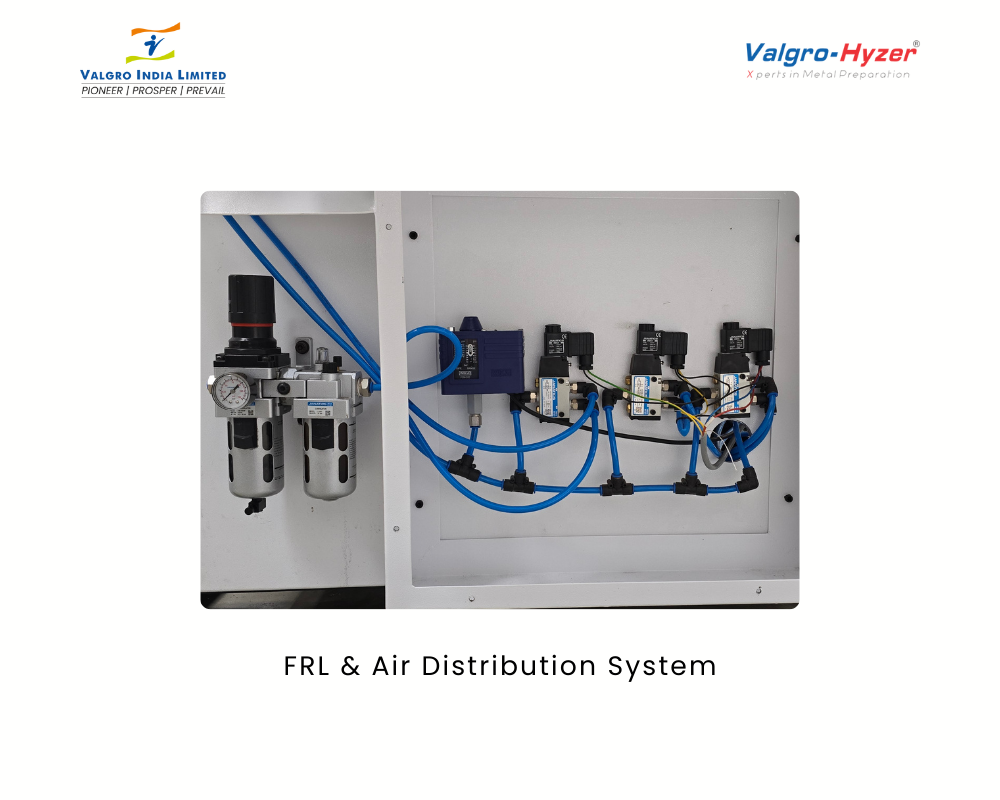

- Advanced Filtration System: Captures dust and particles, ensuring a clean working environment.

- User-friendly Interface: Simplifies operation with easy-to-use controls and settings.

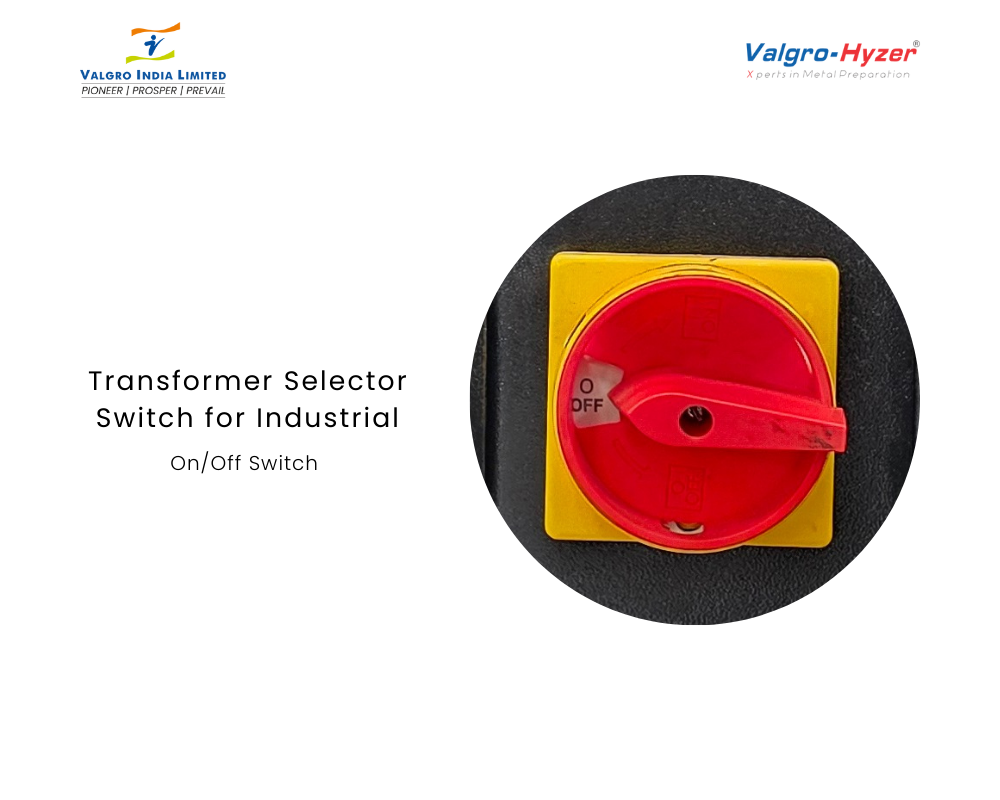

- Separate electrical control for all functions,

- Dry operation dust extraction system

- Adjustable Pressure on Polishing station

- Easy abrasive belt roller replacement

- Adjustable conveyor speed (belt/roller) from) 0.5 to 12MPM

- Surface treatment is possible with different grit combinations.

- Emergency security switch

Customization Options

- Additional Attachments: Optional attachments for specific finishing requirements.

- Automation Compatibility: Can be integrated into automated production lines for increased efficiency.

- Customization: Tailored solutions to meet specific customer needs and applications.

- Application: Designed for the finishing and deburring of stainless steel laser-cut parts.

- Versatility: Suitable for various types of metal sheets.