The Valgro PLR Series is meticulously engineered to meet the precise requirements of Deslagging, deburring and edge-rounding laser-cut sheet metal parts. This cutting-edge machine ensures superior edge quality and surface uniformity, making it an essential tool for modern manufacturing environments.

The PLR Series delivers comprehensive edge processing by precisely treating all inside and outside edges from multiple angles, resulting in a uniform and consistent finish. Its advanced design combines rotation and oscillation to produce a non-directional surface finish, making it ideal for a wide range of applications. With customizable operation, operators can adjust variable disc RPMs and select different abrasive grit sizes for both clockwise and counter-clockwise rotation, providing unmatched adaptability across diverse material types. High flexibility is achieved through models equipped with three triple-planetary head units, enabling the machine to handle various deburring and finishing tasks with ease. The compact, space-saving design allows seamless integration into industrial environments, even where space is limited. An intuitive, user-friendly interface simplifies setup and adjustment of processing parameters, ensuring optimal results for different materials and thicknesses. Engineered for high productivity, the PLR Series maximizes throughput by reducing cycle times while consistently maintaining superior quality.

- Multi-head oscillating planetary head mechanism: Ensures uniform sanding and finishing over a large surface area.

- Adjustable Pressure Settings: Allows for precise control depending on the thickness and type of material.

- Advanced Filtration System: Captures dust and particles, ensuring a clean working environment.

- User-friendly Interface: Simplifies operation with easy-to-use controls and settings.

- Separate electrical control for all functions,

- Dry operation dust extraction system

- Easy abrasive replacement

- Adjustable conveyor speed

- Surface treatment is possible with different grit combinations.

- Emergency security switch

- Multi-Stage Processing: The machine may feature multiple processing stages, to handle different aspects of the deburring and finishing process in one pass.

- Adjustable Parameters: Speed, pressure, and other parameters are adjustable, giving operators precise control over the process to achieve consistent results.

- Low Maintenance: Designed for durability and reliability, the EZ Series requires minimal maintenance, reducing downtime and operational costs.

- Simplifies multi-step processes into one streamlined operation.

- Handles a diverse range of workpieces, from delicate thin sheets to heavy-duty thick components.

- Offers exceptional flexibility and precision for high-quality results.

Application Focus:

The PLR Series excels in:

- Deburring and edge Rounding are suitable for aluminum parts and thin sheet metal to heavy, thick plasma—or air-cut components.

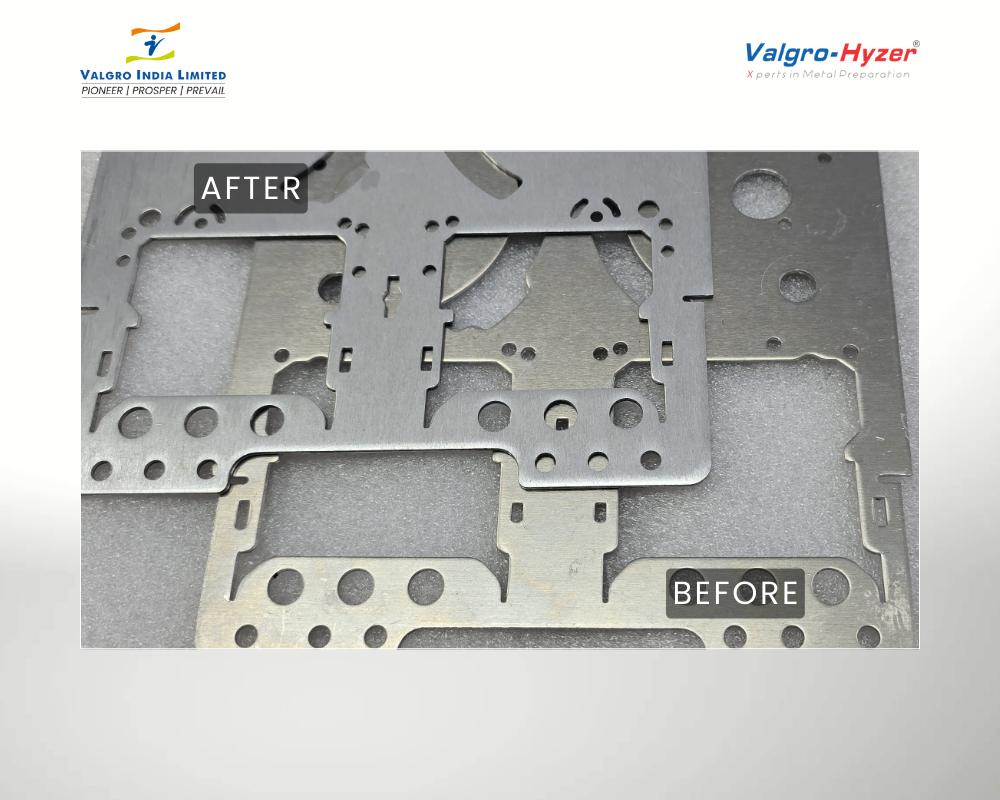

- Slag and Dross Removal: effectively remove residues from plasma and laser air-cut processes.

- Surface Roughening: Ideal for aluminum frames or slightly deformed parts.

- Uniform Finishing: Creates a consistent, non-directional surface finish.