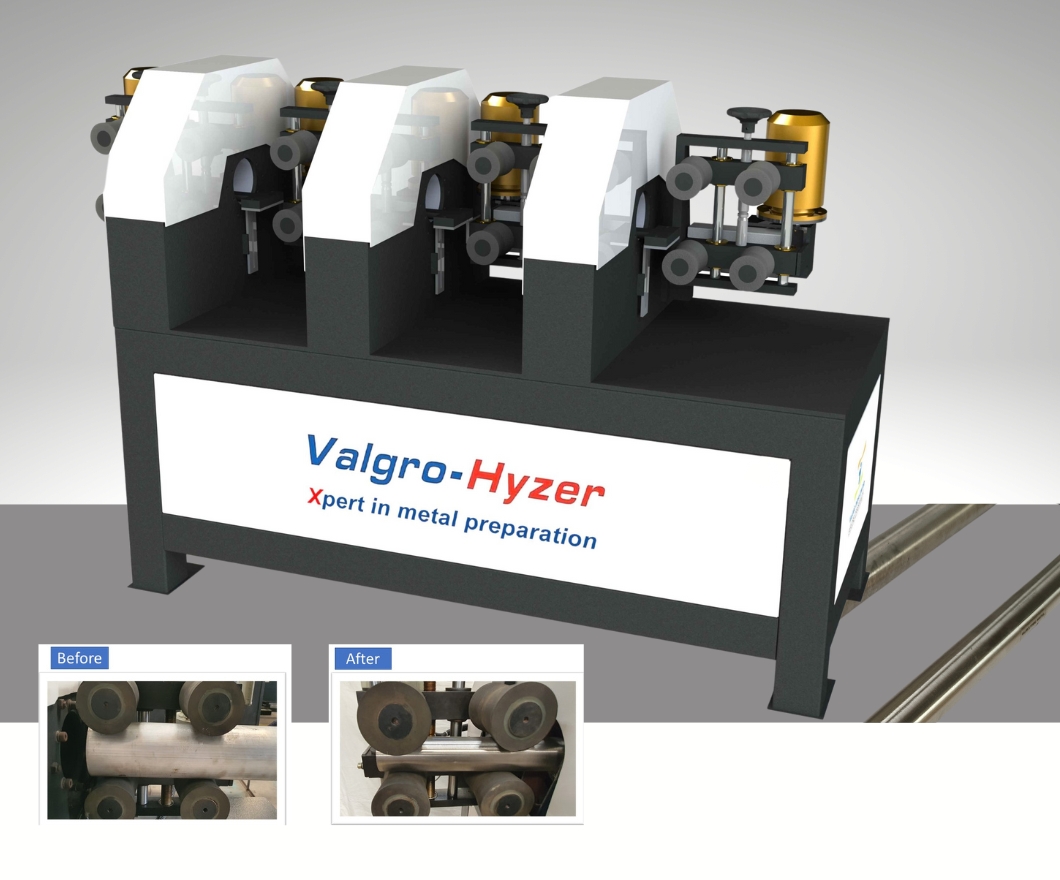

The Valgro Round Tube Pipe Polishing Machine is designed to polish the outer surface of stainless-steel round pipes with high efficiency and precision. The machine features an automatic feeding system that smoothly transports the pipe through multiple polishing heads. After the finishing process, the polished pipe exits onto an inspection table—fully automated, ensuring high-quality output with minimal manual handling. This solution is ideal for applications that require consistent surface finishing and minimal pipe vibration, even on long-length tubes.

Benefits of Planetary Polishing Technology

- Superior Surface Finish

Achieves consistent and smooth polishing with full tube surface coverage. - Enhanced Safety

The non-rotating tube design eliminates the risk of whipping or entanglement during operation. - Process Stability

Low vibration and controlled movement improve polishing consistency, especially on long and thin tubes. - Material Integrity Preservation

Low heat prevents discoloration, warping, or distortion of stainless-steel surfaces. - Versatile Application

Ideal for both straight and curved pipes used in architectural, sanitary, and industrial applications. - Time & Labor Efficiency

Automated feeding and finishing process reduces manual effort, increase productivity, and lowers operating costs. - Quality Control Integration

With an automatic discharge to the inspection table, every polished piece is ready for immediate review and packaging.

Automatic Pipe Feeding System

Ensures consistent material handling and reduces manual intervention.

Stationary Tube Operation

The tube does not rotate; abrasive belts rotate around it for safety and uniform finish.

Planetary Belt Head System

Abrasive belts orbit the tube in a planetary motion for full 360° surface contact.

Minimal Vibration Design

Specially engineered for long-length tubes with reduced movement during processing.

Low Heat Generation

Soft contact with belts reduces friction and thermal stress on the tube surface.

Straight & Curved Tube Compatibility

- Straight tubes: Polished automatically

- Curved/bent tubes: Hand-fed for manual finishing

Integrated Inspection Table

Finished pipes are automatically discharged onto an inspection table for easy quality checks.

Technical Specification

Grinding and Polishing Tube & Rod:

- Suitable for grinding both round and oval tubes

- Suitable for variety of materials such as stainless steel, aluminum, brass, copper, wood