Architects adopted the Valgro brush finishing procedure for its rust-free, rust-resistant, bright, and homogenous surface look.

- More than 25 years of experience in the metal finishing business.

- modern solution provider in the metal finishing industry

- International quality standard with affordable cost

- quick delivery schedules.

- Different brush grits combinations are possible to perform different surface treatment

- Everything in one line with No.4, No.6, Scotch Brite, Hairline Finish

- Synchronise with a full line include Sheet pick N place with One-stop Operational control

The Valgro Scotch Brite roller brush polishing process is rapid and becoming more popular as a finish.

Feature:

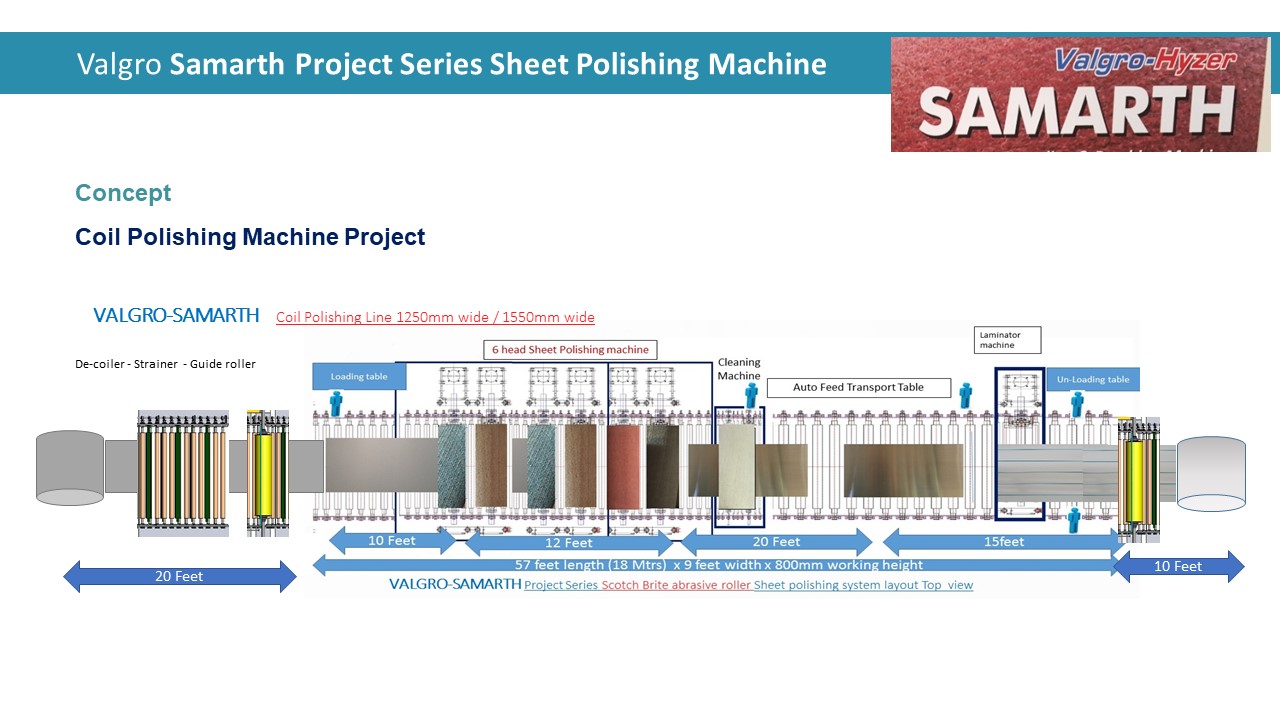

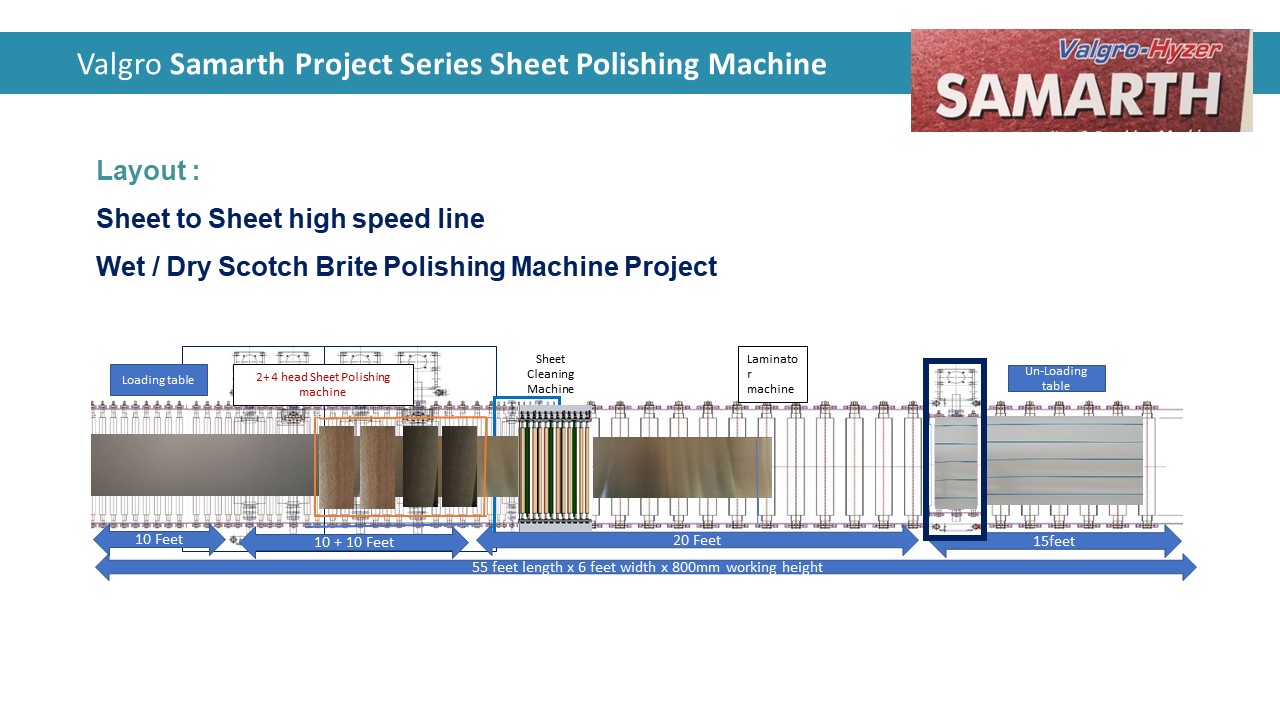

- Multi-head brushing station with 4 or 6 heads

- Horizontal axis rotating and oscillating system

- Soft bright and homogeneous surface appearance.

- Adjustable brushing pressure.

- Wet and Dry both polishing lines (Optional)

- Oil and water mixed, wet type processing

- Dry operation with dust extraction system

- Adjustable Pressure on Polishing station

- Easy abrasives brush roller replacement

- Adjustable conveyor feed speed (Belt / Roller)

- Control by PLC with Touch Screen (Optional).

- Sturdy and latest technological System

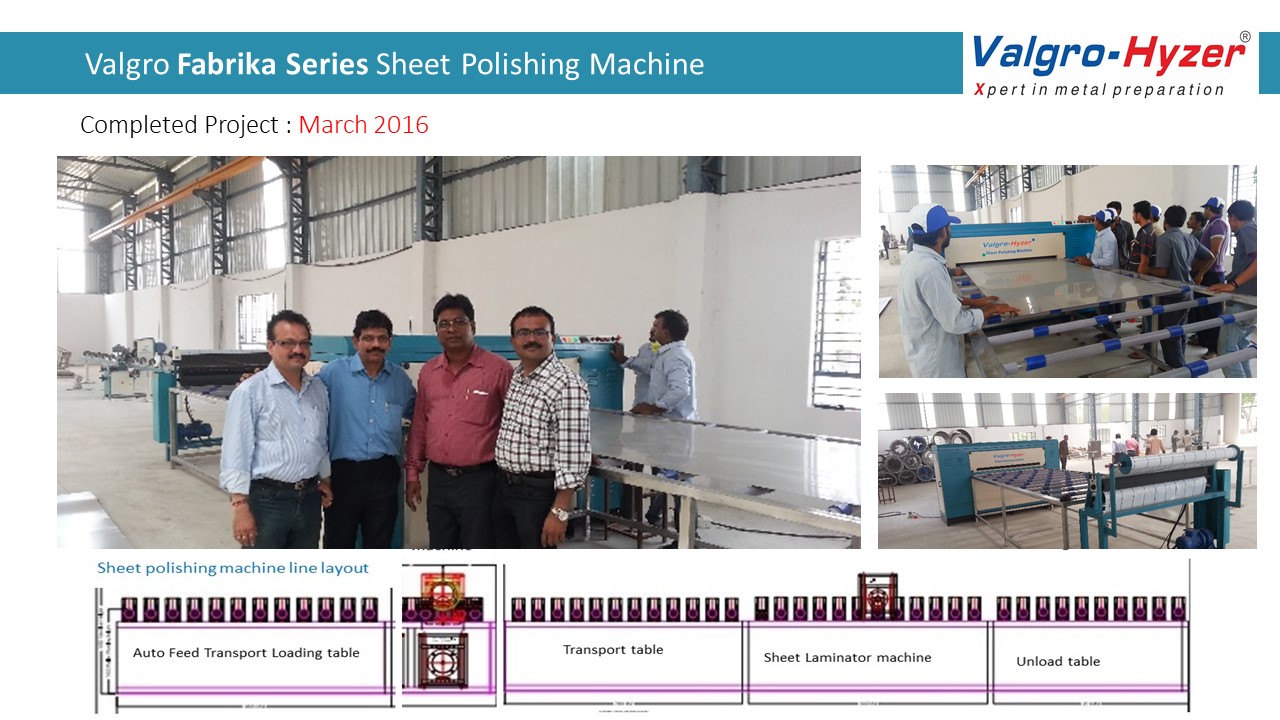

- Sheet Auto Feed Conveyor Transport system (optional)

- External Electrical Control Panel

- Separate electrical control for all functions,

- Adjustable conveyor speed (belt/roller) from) o.5 to 20 MPM

- Emergency security switch

- Reversal conveyor speed for emergency control

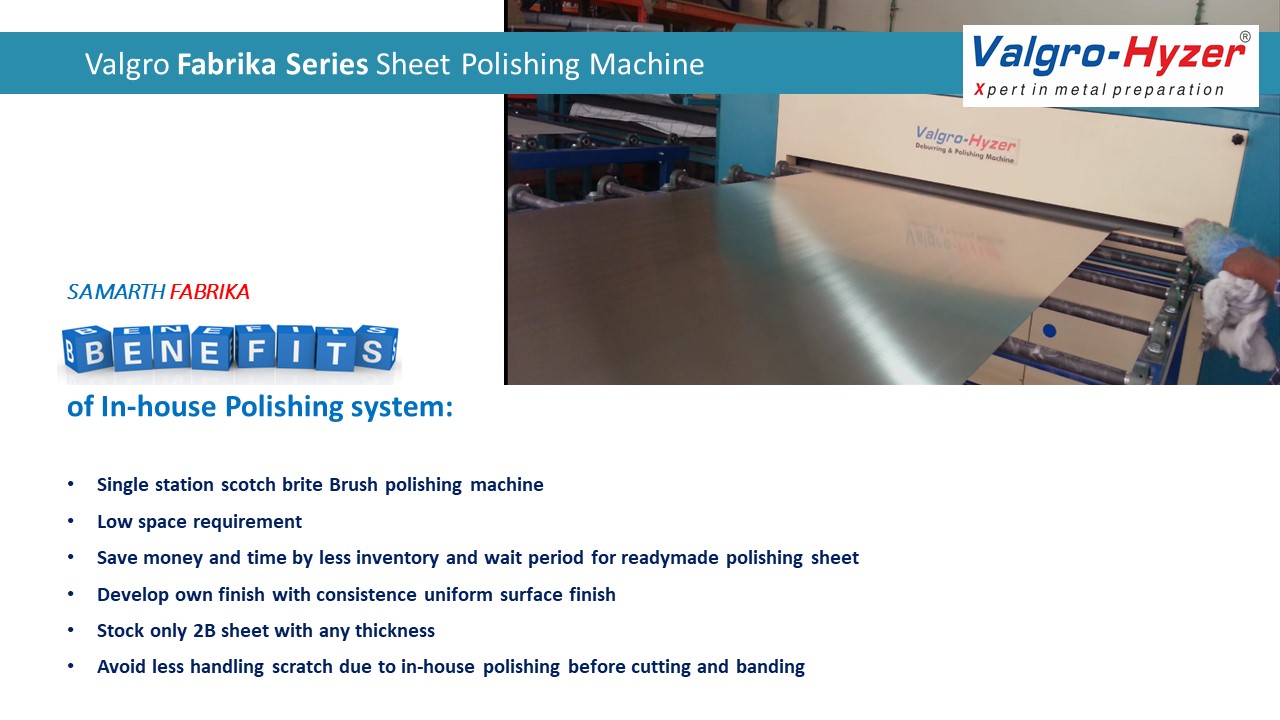

Benefits :

- Rust Free – Rust Resistant Surface

- Easy to Clean

- Consistent Surface Finish

- Low Space requirement

- Save money and time

- Reduce labor and manpower cost

Technical Specification

- Kitchen & Restaurant Equipment Mfg.

- Dairy Food Equipment Process Machinery

- Pharma processing machinery Mfg.

- Packaging Machinery

- Beverage equipment Processing plant

- Escalator, Elevators, and Door

- Public Transport system

- Metro and Railways

- Shipbuilding & Automobile

- Architect Building construction (A.B.C. Sector)