- Perfectly built Recycling System, No environment Pollution.

- Automatic belt tracking pneumatic belt tensioning ensure Optimum.

- Consistency and minimized operational costs.

- Pre-programmable execution settings for part thickness.

- Abrasive belt head and brush head.

- Automatic Thickness Adjustment, with Digital Read-Out.

- Strong Machine Frame, Vibration is well absorbed.

- Large Contact Roller with Perfect Static as well as Dynamic Balance.

- High Spinning And Long life of Abrasive belts is ensured.

- Higher Efficiency.

- Fast Change of Abrasive Belts.

- Best Cost Performance.

Features:

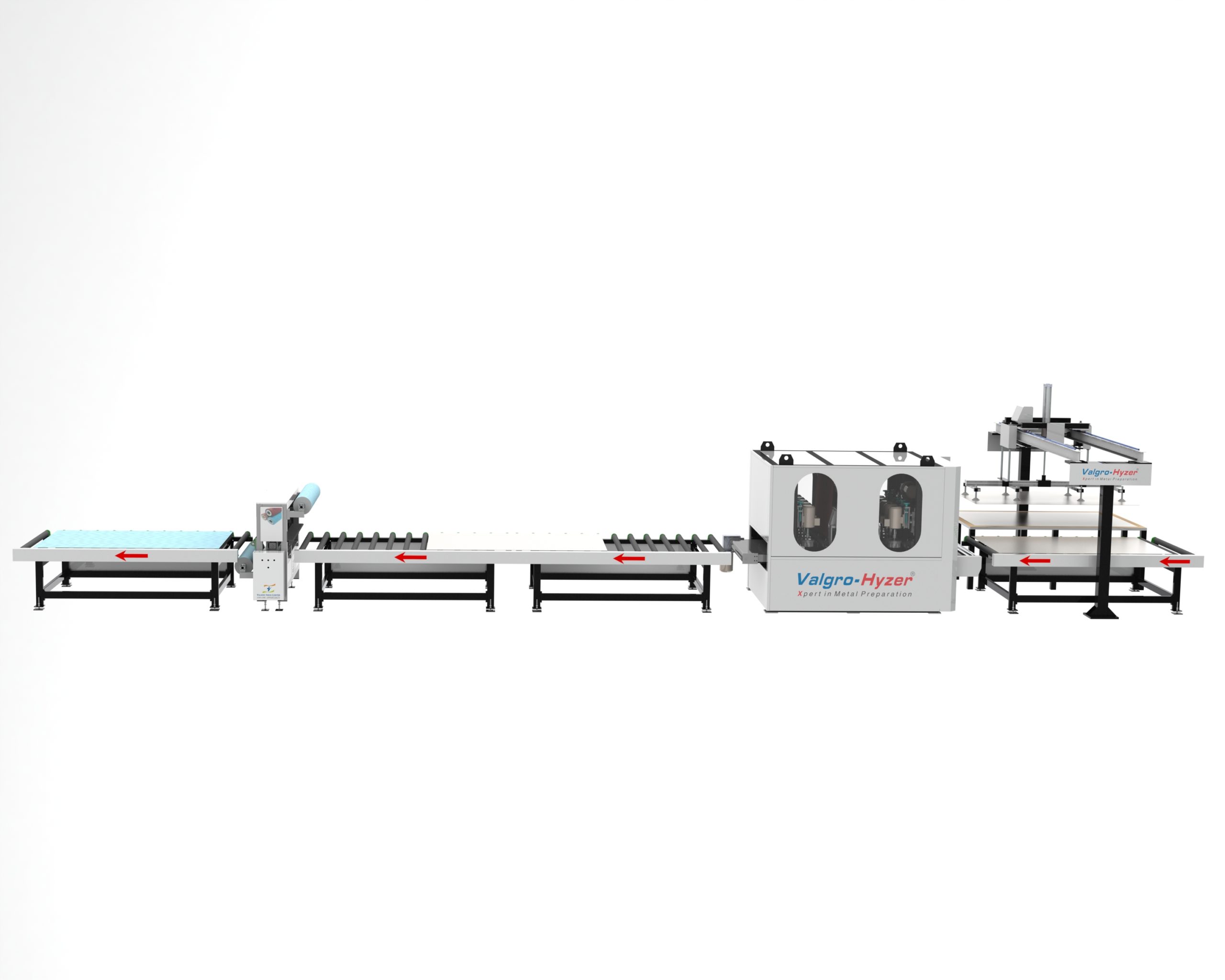

- Multi head Grinding and Polishing station

- Sturdy and latest technological System

- Polishing Station Horizontal axis rotating and oscillating.

- Sheet Auto Feed Conveyor Transport system

- Synchronise with full line with One stop Operational control

- External Electrical Control Panel

- Separate electrical control for all function,

- Dry operation dust extraction system

- Adjustable Pressure on Polishing station

- Easy abrasives brush roller replacement

- Adjustable conveyor speed (belt / roller) from) o.5 to 20 MPM

- Different brush grits combinations are possible to perform different surface treatment

- Emergency security switch

- Reversal conveyor speed for emergency control

Benefits:

- Fastest Grinding Process

- Grinding and Polishing in Single passs

Technical Specification

Custom Build Line

Strip, Sheet & Coil Grinding & Polishing for Stainless Steel Service center