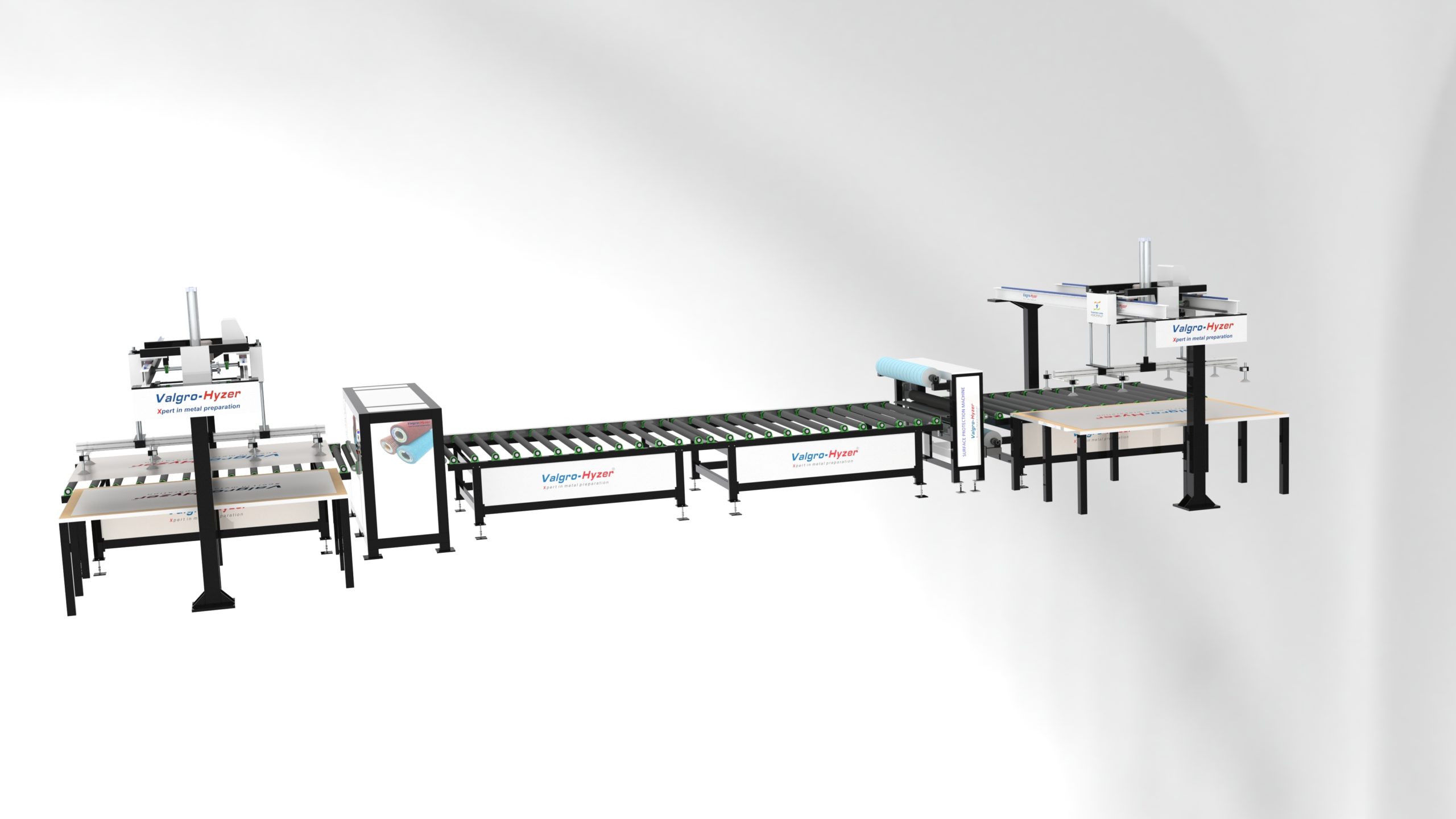

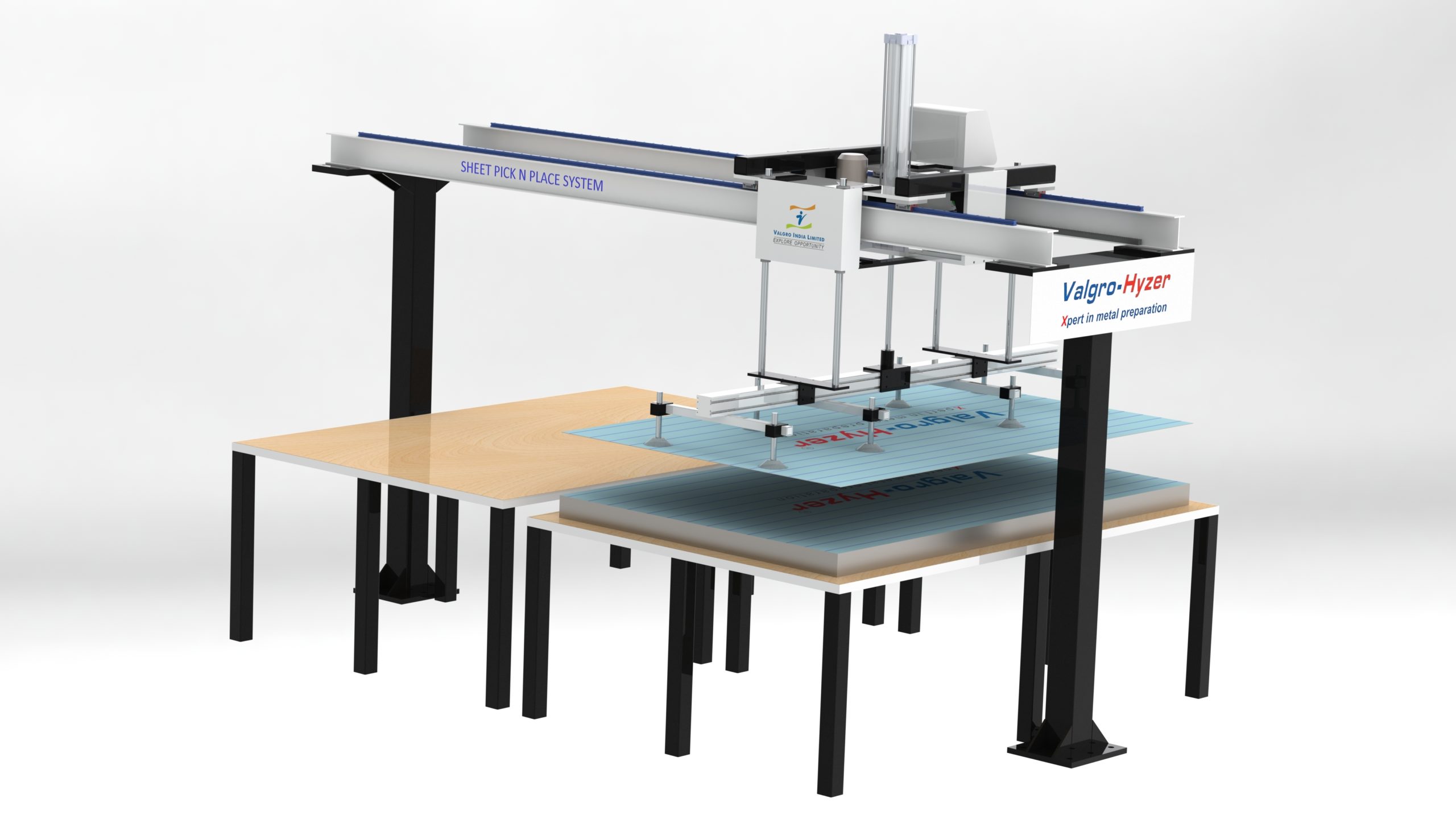

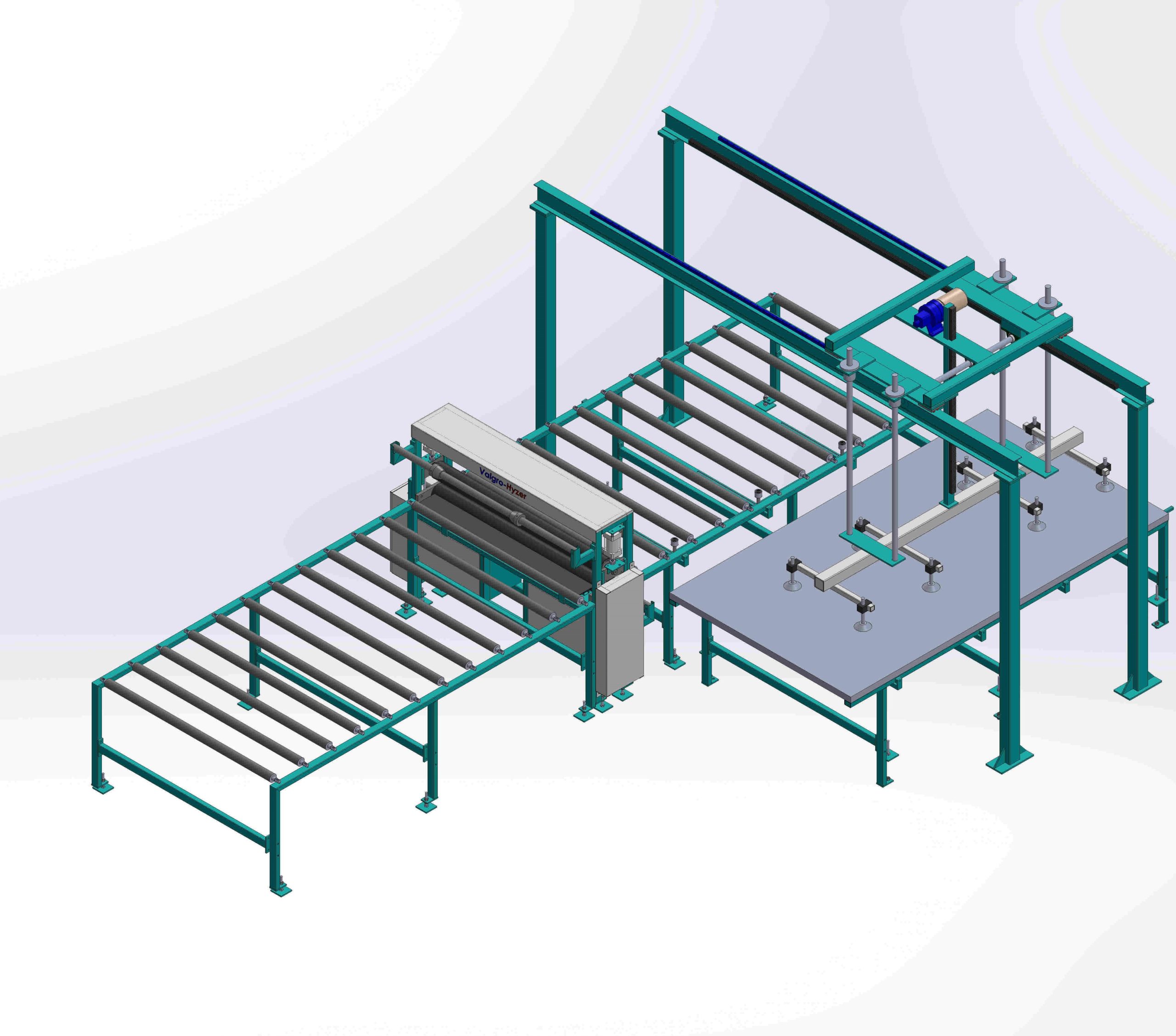

The Valgro Automatic Pick and Place System is designed for high-load sheet handling with a fully automated process. Featuring a vacuum lifting system and controlled by a central PLC system, this innovative solution is equipped with a robust pallet handling system capable of managing up to 3 tons of load. The system incorporates internal lubrication and high-quality, standardized components, providing long-term operational reliability and minimal maintenance.

Features:

- Fully Automatic Operation: No human intervention is required, ensuring a streamlined and safe working environment.

- Pneumatic and Servo-Controlled Systems: Customizable for precise movement and control, catering to various industrial needs.

- Vacuum Lifting System: Designed for efficient and secure sheet pick-up, minimizing damage to materials.

- Pallet Handling System: Capable of managing loads up to 3 tons, optimizing material storage and transport.

- Central PLC Control: Advanced PLC system for centralized control, ensuring precision and coordination across all moving components.

- Internal Lubrication System: Automated lubrication of all moving parts to reduce wear and ensure smooth operation.

- High-Quality Components: All components are of standard make, ensuring high durability and easy replacement if required.

Benefits:

- Increased Efficiency: Automated handling reduces manual labor and boosts productivity, ensuring quicker processing times.

- Enhanced Safety: Eliminates the need for manual handling of heavy sheets, reducing workplace accidents.

- Consistency and Precision: With servo-controlled operations, the system ensures precise and consistent handling of materials, improving the overall quality of the workflow.

- Cost-Effective: By automating the process, labor costs are reduced, and the system requires minimal maintenance due to its robust design and self-lubrication features.

- Scalable Design: The system can be customized and scaled to meet specific production requirements, making it versatile for various industries.

- Load Capacity: 100 kg , 250Kg

- Vacuum Lifting System: Integrated for safe and secure sheet handling

- Control System: Central PLC with real-time monitoring and control

- Lubrication System: Automated lubrication for all moving components

- End Grippers: Custom-designed based on product requirements

- Pneumatic System: Available for custom control solutions

- Servo Control System: Precision handling with scalable configurations

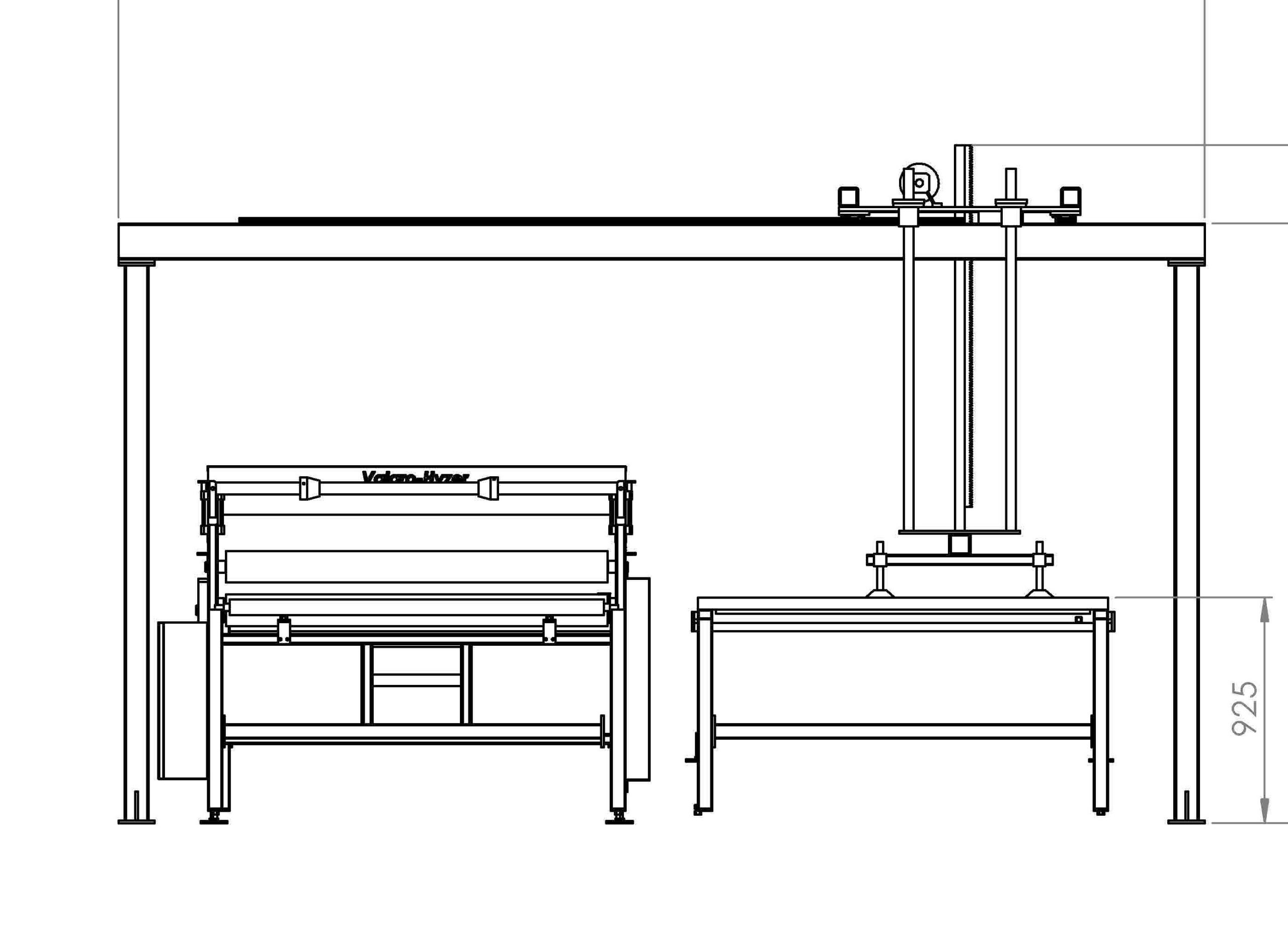

- Installation Requirements: Guide support square pipe or channel for stability; additional technicians recommended for erection at the site

This innovative Valgro Automatic Sheet Pick and Place System offers unparalleled efficiency and safety for modern industrial operations.

Applications:

- Metal Fabrication: Ideal for handling heavy metal sheets in fabricating industries, ensuring smooth, damage-free transfer.

- Automotive Industry: Suitable for assembly lines where sheet handling needs to be precise and consistent.

- Warehouse and Logistics: Perfect for large-scale warehouses where heavy materials are frequently moved.

- Manufacturing Plants: Supports mass production processes, enhancing material handling efficiency and workflow management.