For a flawless finish, you need a complete solution.

For a flawless finish, you need a complete solution.

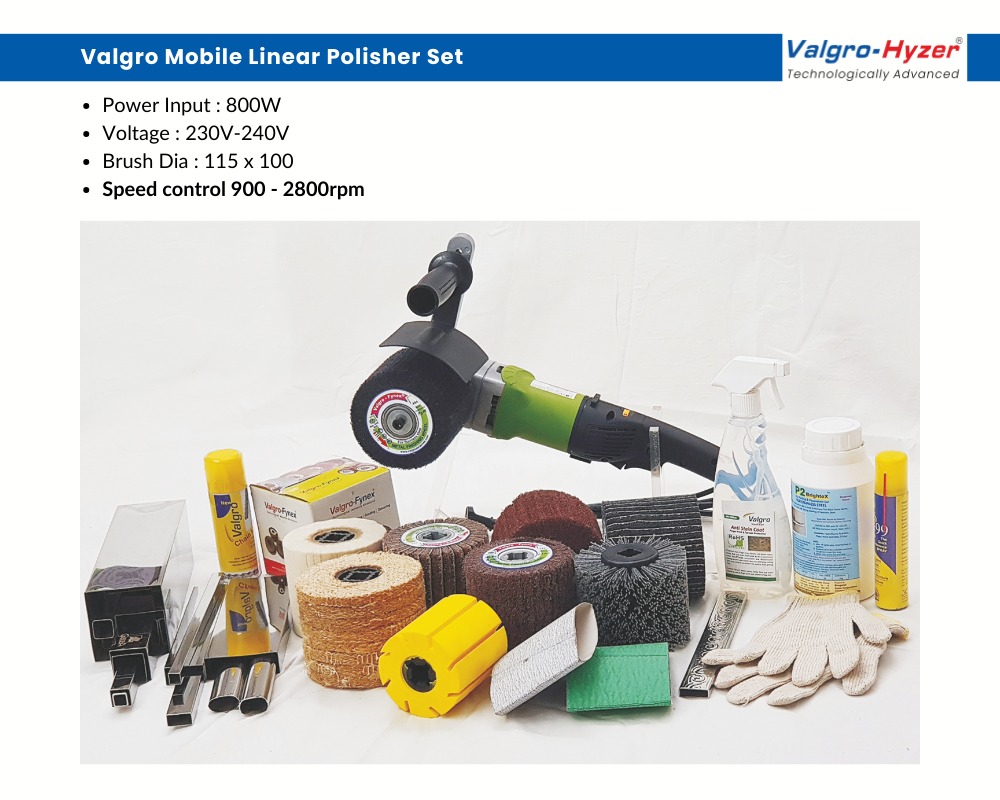

The Valgro Linear Finishing Full Kit is engineered for precision finishing and surface preparation. It effectively handles stainless steel friction finishing, deburring, and polishing tasks. This comprehensive set is tailored to simplify your workflow and deliver outstanding results with minimal effort.

Abrasives & Consumables

The kit includes a range of premium-quality abrasives designed to cater to various finishing needs:

- Non-Woven Wheels: Ideal for creating a uniform satin finish.

- Interleaved Wheels: For blending, polishing, and achieving a fine decorative finish.

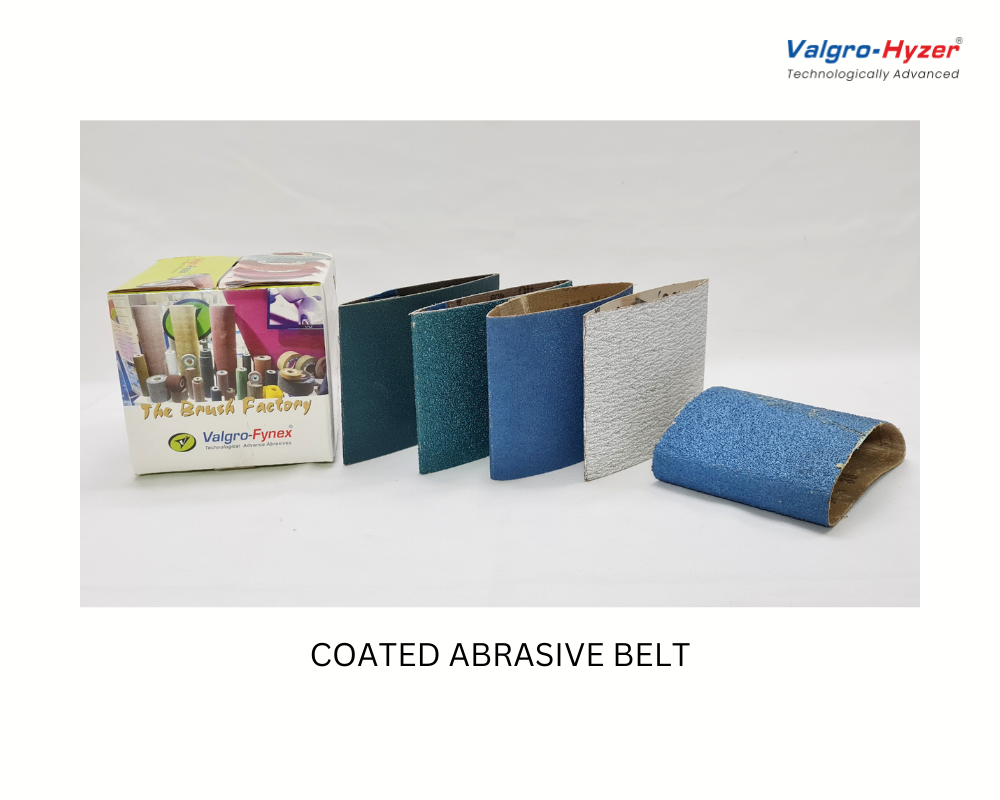

- Abrasive Grinding Belts: Ensure effective material removal and surface refinement.

- Expandable Rubber Drum: Provides excellent flexibility for contour sanding.

- Valgro Kombi Brush (115mm x 100mm): Ideal for versatile finishing applications.

- Valgro Finishing Brush (115mm x 100mm): Achieves smooth and polished results.

- Pickling and Passivation Gel: For removing weld discoloration and enhancing corrosion resistance.

- Antifinger Coating Chemical: Provides a protective layer to maintain the finished surface.

- Gloss Mirror Polishing Cloth Wheel: Ensures a high gloss, mirror-like finish.

- Lustre Bar for Mirror Polish: A vital compound for achieving perfect mirror polish results.

- And Much More

Powerful Performance: Equipped with a high-torque motor for efficient and consistent finishing.

Powerful Performance: Equipped with a high-torque motor for efficient and consistent finishing.- Variable Speed Control: Ensures flexibility for different finishing requirements, from aggressive material removal to fine polishing.

- Ergonomic Design: Lightweight and comfortable to handle, reducing operator fatigue.

- Versatile Applications: Suitable for flat surfaces, curved edges, and hard-to-reach corners.

- Quick Change System: Enables fast and tool-free abrasive changes for improved productivity

- Rated Input Power: 800 W

- No-load Speed: 800–3000 RPM

- Spindle Diameter: 19mm

- Abrasive Tool Diameter: 115mm OD x 100mm Width x 19mm ID

- Weight (without power cable): 1.9 kg @

- Cable Length: 2 m / 6 ft @

- Noise Emission:

- Sound Pressure Level: 91 dB(A)

- Sound Power Level (LwA): 102 dB(A)

- Uncertainty of Measurement K: 3 dB (A)

Applications

- Kitchen & Restaurant Equipment Mfg.

- Dairy Equipment

- Food Process Machinery

- Pharma processing machinery, Mfg.

- Packaging Machinery

- Beverages equipment Processing plant

- Escalator, Elevators, and Door

- Public Transport system

- Metro and Railways

- Shipbuilding

- Automobile

- Architect Building Construction

Benefits

- Comprehensive Solution: Covers the entire finishing process from grinding to polishing.

- Time-saving Efficiency: Reduces manual labor and ensures faster completion of finishing tasks.

- Enhanced Surface Quality: Achieves uniform grain patterns, reducing rework and enhancing product aesthetics.

- Durability and longevity: Built with robust materials to withstand demanding workshop conditions.

- Cost-effective: minimizes abrasive waste and improves overall operational efficiency.