Polishing Compound feeds the workpieces continuously from the source and then is filtered & recycled by the assistant filtering system, which will afterwards, feeds the cleaned compound back to its source for reuse.

After Polishing is done, workpieces will be processed by the following cleaning & drying unit before they are laminated with Protective Film for usage or further treatment.

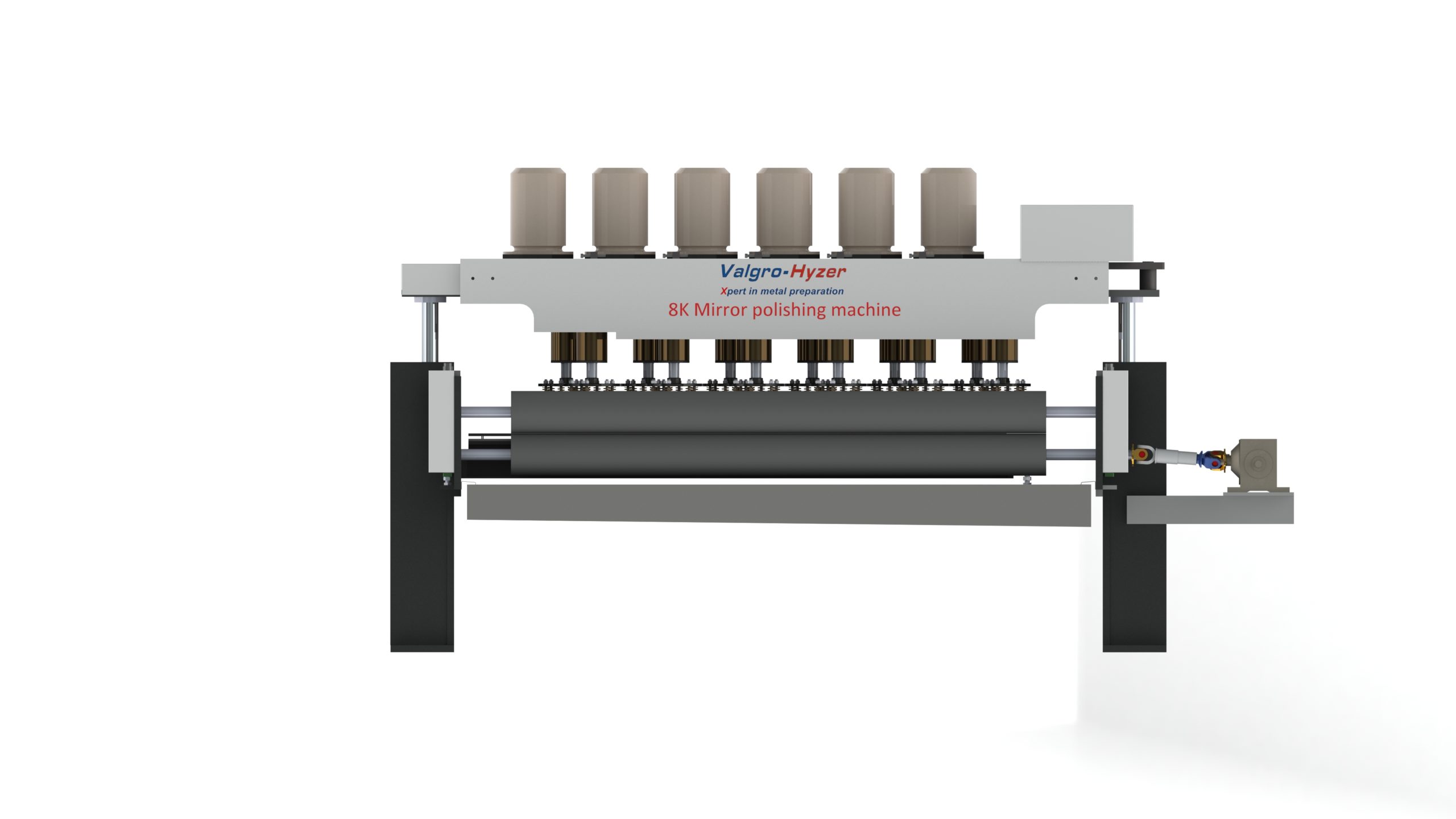

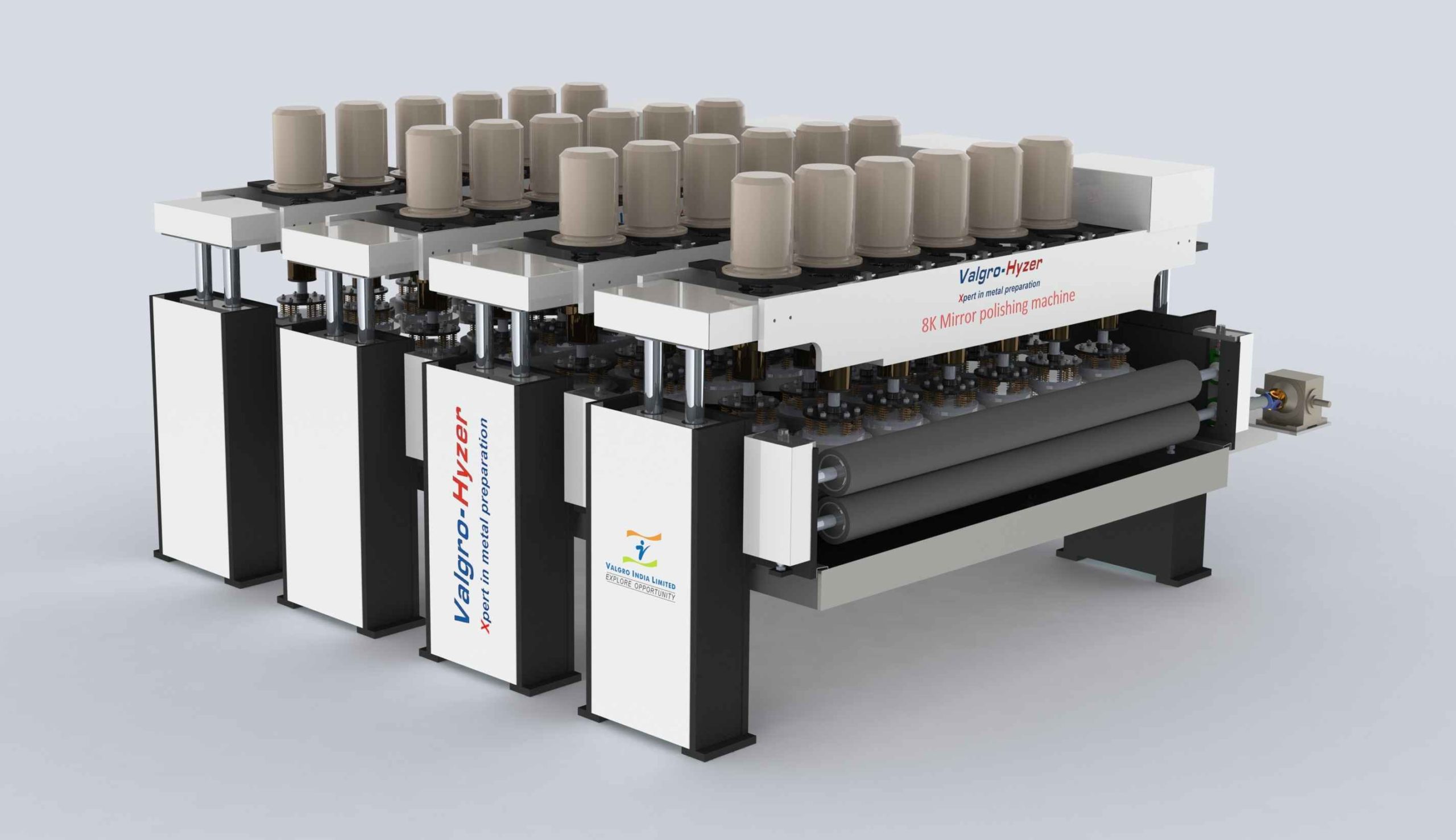

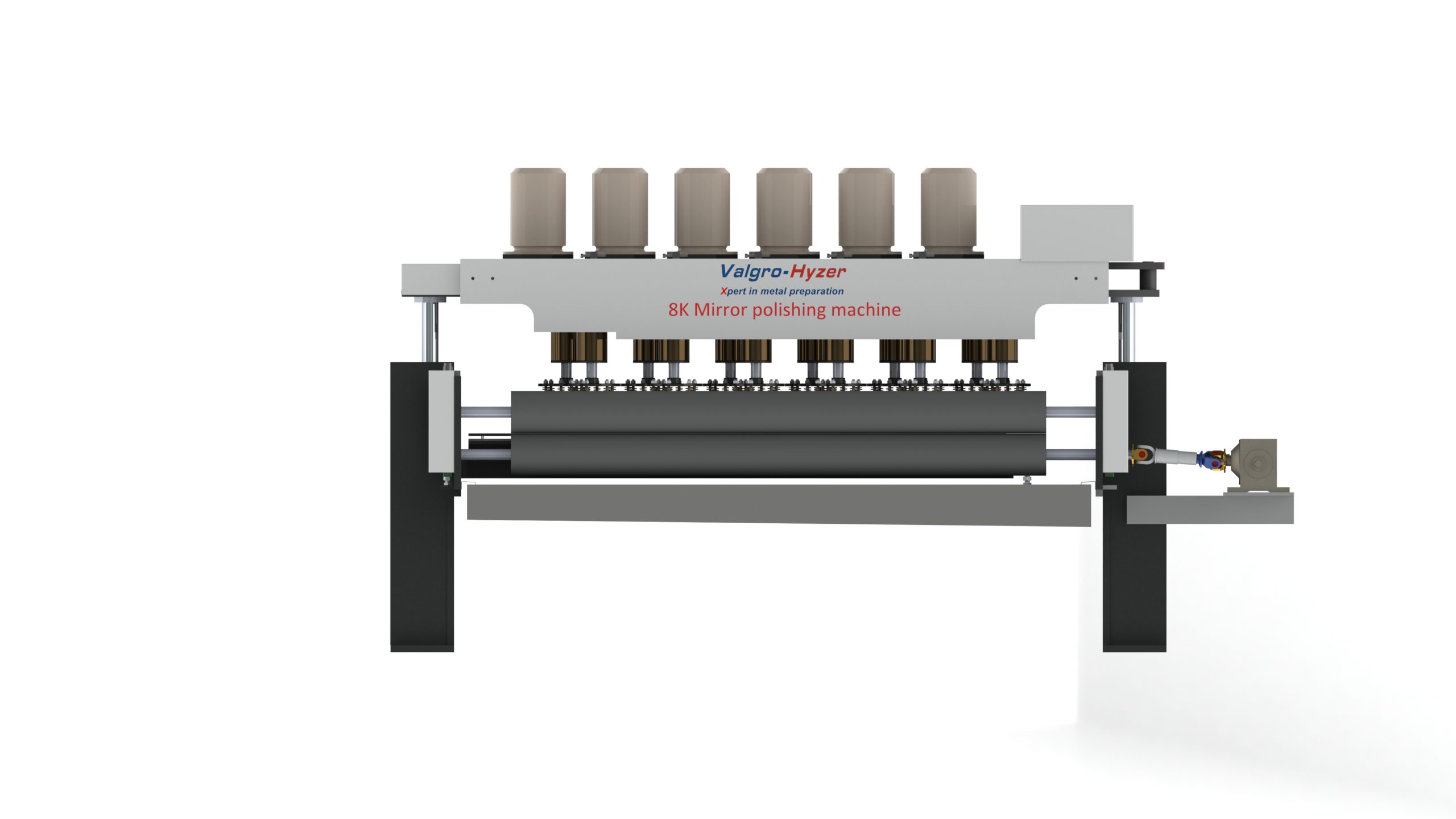

Feature:

- Environment Friendly

- High Working efficiency

- Compact Design

- Stable Oscillation System

- Adjustable Transmitting Speed

- Adjustable Polishing Pressure

- Fast Change of the Polishing heads

- Perfect Cleaning & Drying Unit

- Large Machine Space for Maintenance and Repairing.

- Easy Operation

Benefits:

- Liquid compound will be recycled and reused, No Compound leakage or Splash.

- Low Operation Cost.

- Machine parts are free from being etched by Polishing Compound.

- Vibration lines are avoided

- Forward and Backward Transmission

- Fast Change of the Polishing heads

- Automatic thickness Adjustment, With Manual Assistance

- No Watermark or dirt is left after Laminating

- Best Cost Performance

Technical Specification

- The reflectivity of Super Mirror creates light and space and is easily fabricated, it has reflectivity of Glass Mirror, but unlike Glass Mirror, It will not cause the so-called Light Pollution, Which is why it is widely used in Modern Society.

- Typical Application of Mirror Polished sheet is elevator, escalator, interior cladding, building facades, Medical & Chemical purpose, etc.

- Mirror Polished Sheets or plated can be further treated with Etching, PVD, or other processes.